In June 2006, US-based pharmaceutical company Bristol-Myers Squibb pledged to build a large-scale multi-product biopharmaceutical manufacturing plant in Devens, Massachusetts.

The development, named Project Hummingbird by the company, was earmarked for the site near Harvard due to several factors, including tax incentives, the availability of an educated workforce and the existing infrastructure.

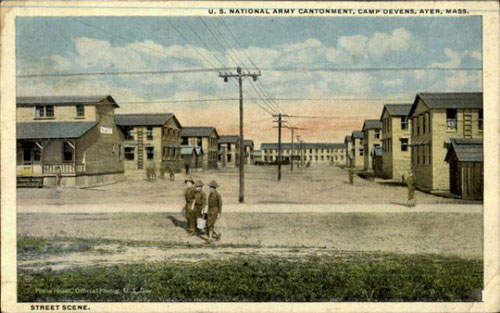

The site is situated on a former army base 35 miles north-west of Boston, which used to be called Fort Devens. As such, substantial service infrastructure is already in existence. The site was bought by MassDevelopment for $17m in 1996 and has been developed as a business park ever since.

The facility’s construction began in May 2007 and was operationally complete by 2009. The validation process for commercial production began in February 2010, when Bristol-Myers Squibb applied for US Food and Drug Administration (FDA) regulatory approval of the facility. In May 2012, the FDA approved the facility for the production of Orencia.

The project required an investment of around $750m. Its first phase employed around 350 personnel, while subsequent phases required more than 550 workers.

Details of the Bristol-Myers Squibb facility in Devens

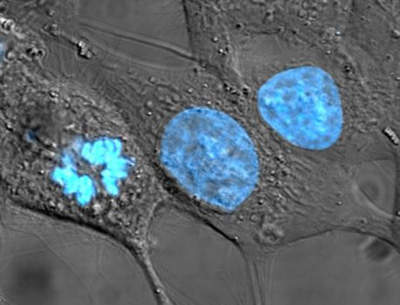

The plant will manufacture multiple biotech products, but will initially manufacture orencia (abatacept), a rheumatoid arthritis (RA) drug (T-cell co-stimulation modulator). Orencia is the company’s first approved biotechnology drug and is expected to generate $1.1bn in sales in 2012.

Orencia intravenous (IV) infusion formulation was approved in 2005. In August 2011, the subcutaneous (SC) formulation of orencia (abatacept) was approved for the treatment of RA in adult patients.

Bristol-Myers Squibb has also developed Nulojix (belatacept), a kidney transplant drug that will be manufactured at the facility. The drug was approved by the US FDA in June 2011.

In April 2010, the biologics manufacturing facility received Leadership in Energy and Environmental Design (LEED) Silver certification. This certification was granted to the facility’s laboratory and office building in December 2009.

Construction of Bristol-Myers Squibb’s Devens plant

The project involved building six 20,000l bioreactors, one purification train and several tower pipe racks measuring more than 100ft high.

There are five main buildings, including a central utility building, large-scale cell culture manufacturing building, quality control/quality assurance and cafeteria/administrative block, warehousing building, chemical storage building and wastewater pre-treatment plant.

The plant has been built in a modular fashion, which is intended to make subsequent expansions to increase its capacity easier.

The facility was built by Fluor Corporation and Parsons Corporation, companies based in South Carolina and California respectively.

The design phases for two of the buildings (lab/office and manufacturing) were overseen by local consultant Vanasse Hangen Brustlin (VHB), with the aim of facilitating LEED certification for these sections of the facility.

Bristol-Myers Squibb completed the Phase II expansion at the Devens facility in May 2016. The $280m expansion added a biologics development building and a clinical manufacturing building to the site.

Wastewater facility at the biopharmaceutical manufacturing plant in Devens

The $600,000 wastewater pre-treatment plant, set in a building with 5,000² of floor space, is designed to handle a flow capacity of 530,000gal a day. This includes a redundant system with a 265,000gal capacity for each component.

The system handles wastewater from the bioreactors, used buffer solutions and blowdown from the cooling tower and boiler.

The contractors responsible for installing these systems were O’Brien and Gere (architect and engineer), Fulcrum Associates (construction manager), Brookside Co, Overhead Door Co, Structural Systems, Ten Sales, Universal Steel Erectors, and VP Buildings.

The system uses two 265,000gal sequencing batch reactors for biological treatment, together with two 200,000gal wastewater equalisation tanks.

Incentives for Bristol-Myers Squibb choosing Massachusetts

Bristol-Myers Squibb was awarded $33m in tax credits by the state of Massachusetts, following legislation that changed the state’s investment tax credit rules such that the company could claim a refund for 5% of its investment in the facility.

The state also put through a $34m bond issue for infrastructure relating to the new biopharma plant, along with new waste treatment and sewage facilities. The total incentive awarded to the company has been estimated at around $60m.