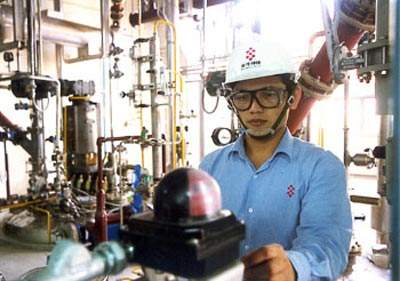

The ScinoPharm bulk pharmaceutical plant is located at the Tainan Science Industrial Park in Shan Hua, Tainan County in southern Taiwan.

The company produces bulk active pharmaceutical ingredients under contract for other pharmaceutical companies. This lucrative subcontracting market sees the production of around 50 main raw materials, which are the precursors for higher-level products.

Project make-up

ScinoPharm was first set up in the US in 1994 as a bulk material subcontractor to major pharmaceutical firms. The first phase of the plant was declared finished in the last quarter of 1999 and the second phase started in January 2000. This was completed ahead of schedule in Q4 2001.

The total cost of the project for construction and outfitting was in the region of $125m, which was $32m under budget.

The administration buildings, technology buildings, a wastewater processing plant and the main factory were completed in the first phase of the project. The total plant area is 200,000ft².

VECCO and Fu Tai Engineering were the contractors for the construction of Phase I and Phase II.

Batch automation solutions

Fisher-Rosemount Systems supplied ScinoPharm Taiwan with a DeltaV scalable process system, which was chosen due to its expanded input / output (I/O) capacity and the advanced batch software of DeltaV Version 3.

The installation was carried out in two phases. Phase I commenced in June 1999, while Phase II began in December 1999. The project cost $3.5m.

Phase I of the project required more than 4,000 connected I/O devices, 12 operator stations, and 20 programmable logic controllers (PLC) connected to DeltaV by open platform communications (OPC) technology.

Phase II added an additional 4,000 I/O and another nine operator stations. The systems were installed by FuTai Engineering, which was the general contractor for the project. The plant also benefits from highway addressable remote transducer (HART) instrument control.

Water systems for ScinoPharm

In December 2002, ScinoPharm realised that the raw water supply within the park was not of a high enough quality to support a contract active pharmaceutical ingredient (API) production facility.

The raw water supply needed to be treated to attain World Health Organization (WHO) potable water standards and provide different levels of ultrapure water throughout the facility.

In addition, the company needed to be able to treat all facility wastewater to meet discharge standards.

To solve these problems the engineering / design firm ZENON was awarded the contract to be the full-service supplier / installer of suitable systems. Zenon was able to install:

- A centralised raw water supply treatment system to meet WHO water standards

- Multiple laboratory point-of-use (POU) water purification units for the entire facility

- A centralised United States Pharmacopeia (USP) water system with installation qualification (IQ) / operational qualification (OQ) validation documentation

- A denitrification membrane bioreactor (MBR) wastewater system for variable solvent laden wastewater

The system was designed, fabricated and installed by December 2002, making ScinoPharm the first pharmaceutical research and development (R&D) and manufacturing facility in Taiwan to meet USP requirements.

The central raw water supply treatment was achieved with a packaged treatment system, incorporating duplexed media filtration and water softening with pre-chlorination chemical injection at the treatment system.

The POU system requirements were fulfilled using several ZENON Ultra-70 bench-top laboratory systems. These systems incorporate pre-filtration for chlorine removal, reverse osmosis (RO) for type III water generation and storage with a POU discharge port. The type III water reservoir is the supply source for the post IX, ultrafiltration (UF) for pyrogen removal and final absolute filtration prior to a second type I water POU discharge port.

The centralised USP water system is comprised of a ZENON high-resistivity double pass RO (DPRO), achieving USP XXIV water quality requirements without post-treatment. A 30 US galleon per minute (US gpm) UF system was included for loop distribution to ensure pyrogen-free distributed water. The system was supplied with a complete IQ/OQ validation support package.

The 65,000 galleons per day (gpd) (250m³/d) wastewater treatment system treats all R&D and production wastewaters aerobically with a ZeeWeed membrane bioreactor (MBR) system, including denitrification.

The wastewater is highly variable with high solvent concentrations. The influent chemical-oxygen demand (COD) of 50,000mg/l is effectively degraded to a final effluent concentration of less than 500mg/l.

Plant facilities operation and products

The facility is able to realise commercial production using a variety of batch processes from 20l to 8,000l.

It also has the capability for high-potency products and bulk for sterile dosage forms.

In addition, the plant has an integrated management information system using a distributed control system (DCS), manufacturing resource planning (MRP) and laboratory information management system (LIMS).

The plant has seven operating areas designed to handle any scale of production from kilo-lab scale 1kg up to a commercial scale of 100kg.

The plant produces a range of products, including Paclitaxol, Mestranol, Riluzole, Flumenazil and Lisinopril. It is staffed by approximately 285 employees. The company also has an R&D facility in Shanghai, China that employs 40 personnel.

Biotechnology at ScinoPharm

The ScinoPharm biotechnology plant in Tainan was started in 2003 and was completed on schedule in Q2 2004.

The plant required an investment of $35m and produces recombinant proteins and monoclonal antibodies.

The reactors range from 20l to 8,000l and the plant employs 100 staff.

The plant will work closely in conjunction with a ScinoPharm biotech subsidiary, which is working in the drug discovery area. The plant will also provide contract manufacturing services for the worldwide biotech industry.