US-based pharmaceutical company Pfizer broke ground for the development of a Global Biotechnology Centre in China’s Hangzhou Economic Development Area (HEDA) in June 2016.

The company announced that it will invest around $350m to develop its first biotechnology centre in Asia to support China’s national healthcare reforms to provide world-class biological medicines for patients worldwide.

The biotechnology centre is expected to be fully operational by 2018. The company expects that the facility will increase the complexity and value of China’s biopharmaceutical manufacturing sector by 2025.

Details of Pfizer’s Global Biotechnology Centre

The Global Biotechnology Centre is intended to ensure the production of high-quality, affordable biosimilars using technologies that meet international standards of quality, safety, efficacy, construction and superior environmental standards.

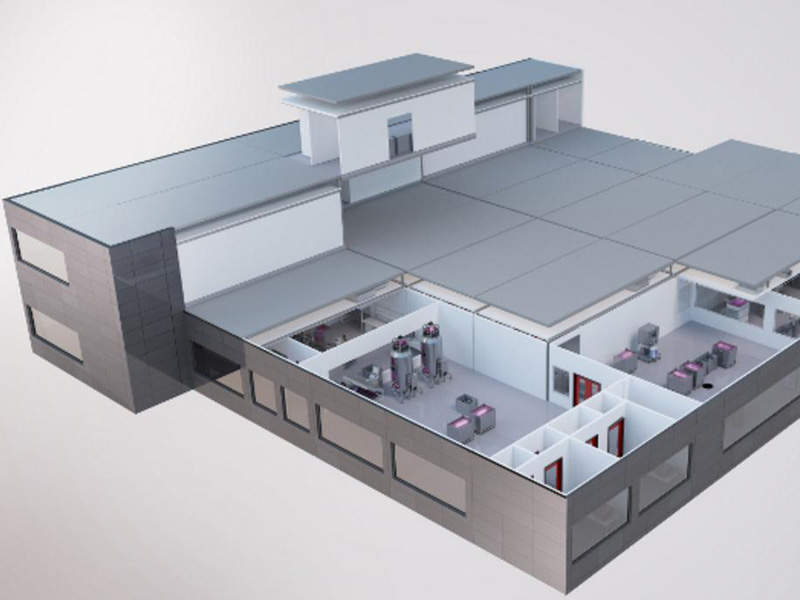

It will house Pfizer China’s biosimilars and biologics quality, technical services, divisions for engineering and logistics, commercial manufacturing, process development site and clinical supply site.

It will also contain filling and packaging units for accommodating start-to-finish manufacturing capabilities in a single facility.

Construction of Pfizer’s biotechnology centre in Hangzhou

The facility will make use of GE’s KUBio modules, which will be prefabricated with Flexfactory processing technology, to reduce construction and installation time. The technology is claimed to reduce carbon dioxide emissions, water usage and energy consumption by 75%.

The advanced modular solutions installed with the Flexfactory bioreactors will be used for growing cultures and manufacturing biologics.

The KUBio pre-fabricated modules will be shipped from Germany to China and assembled on-site. The modules usually consist of biomanufacturing platforms with around 250 components such as single-use technologies, associated process hardware, automation and control components to provide end-to end manufacturing of biosimilars.

Benefits of Pfizer’s Global Biotechnology Centre

The Global Biotechnology Centre is expected to generate more than 150 jobs during its operation phase and strengthen regional biotechnology expertise.

Its establishment will represent Pfizer’s further investment in research and development (R&D) and clinical research and contribute to the growth of China’s biopharmaceutical industry.

The facility also contributes to growth in local and government economy by attracting additional investments from both domestic and foreign sources into sectors such as healthcare and R&D.

Marketing commentary on Pfizer

Pfizer is dedicated to discovering and developing new and improved solutions to prevent or treat diseases and healthcare challenges.

The company works in partnership with healthcare providers, managed care organisations, world governments and non-governmental organisations to provide access to patients across the world to innovative treatments and quality health care.

Pfizer’s leading medicines and products portfolio supports wellness, prevention, treatment and cure for diseases in different therapeutic areas.