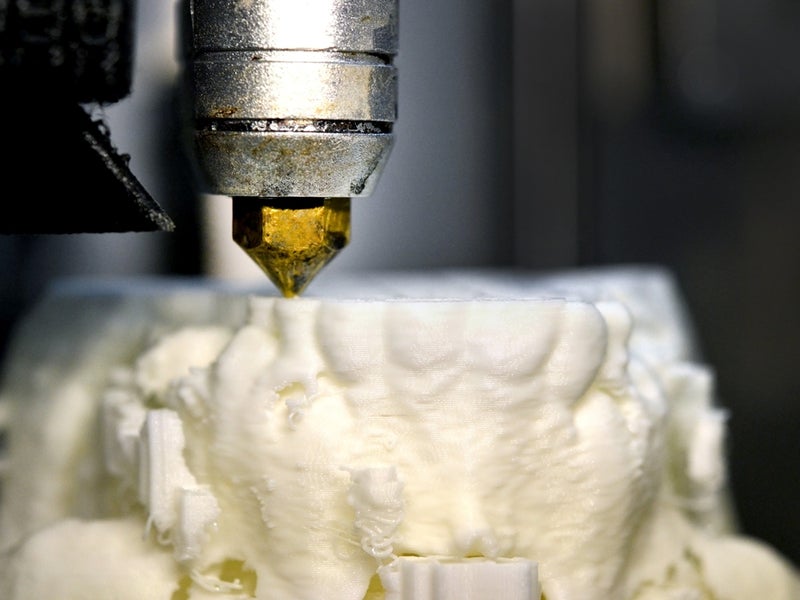

In healthcare, 3D bioprinting is used to create living human cells or tissue for use in regenerative medicine and tissue engineering. Organovo and EnvisionTEC are the pioneers of this technology. 3D printing is also used to manufacture precision and personalised pharmaceuticals. Aprecia Pharmaceuticals’ Spritam for epilepsy is the first and only FDAapproved 3D printed drug.

Listed below are the key healthcare trends impacting the 3D printing industry, as identified by GlobalData.

Use of 3D Printing to fight the Covid-19 pandemic

The rapid proliferation of Covid-19 has been putting great strain on healthcare systems across the world, with demand for critical medical equipment and supplies mounting. Major manufacturers to individuals, have responded to the Covid-19 crisis by supporting the production of vital medical equipment for hospitals. 3D Systems, Carbon, and Renishaw have begun designing and manufacturing open-source PPE for healthcare workers worldwide.

Use of 3D Printing in regenerative medicine

There is a major health crisis in terms of the shortage of organs, as the population is living for longer due to medical advances. Since 2013, the number of patients requiring an organ has doubled, while the actual number of available donor organs has barely moved (HRSA, 2020).

Regenerative medicine involves many different areas, using scaffolds, biomaterials, cells, or a combination of biomaterials and cells to attempt to create organs for transplants instead of relying on the current donor model. Recently, the creation of multilayered objects (tissues/organs) from soft biomaterials such as living cells and biomimetic synthetic polymers has been the most challenging technological advancement in the field.

Although many problems need to be solved for complex organs (such as the heart or liver) to be 3D bioprinted and subsequently transplanted into a patient, simple organs such as the bladder have been transplanted into patients since the early 2000s.

Use of 3D Printing in personalised/ precision medicine

3D printing offers a completely new opportunity for the development and preparation of personalised medicines at both the pharmacy and industrial scale. Introducing 3D printers to pharmacies and hospitals would allow physicians, nurses, and pharmacists to form a dose and delivery system based on the patient’s body size, age, lifestyle, and sex. This would make medicine personal to the patient, and also save money and resources.

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalDataAprecia Pharmaceuticals is the only company with an approved 3D printed pharmaceutical, Spritam for the treatment of epilepsy.

Streamlined and more efficient R&D processes

There is a growing R&D crisis occurring in the pharmaceutical industry, as drugs are failing at later and later stages. Bioprinted tissues and organs are already being used to help increase the success rate of clinical trials. With bioprinting, researchers can print fully functional organs made of human cells to test a drug’s efficacy prior to using in vivo animal or human tests. This not only reduces the damage caused to animals, but also expedites the entire R&D process.

Accessibility

Pharmaceutical R&D and production is expensive. In many Western countries, the cost is supplemented in some way by the government, but in other areas worldwide, particularly poverty-stricken countries, there is simply no viable way for these patients to afford treatment. Additive manufacturing promises to bridge that divide. 3D printing is already being implemented to produce pharmaceuticals by the US company Aprecia.

Prosthetics have historically been expensive. Certain organisations have been designing prosthetics that can be 3D printed from commercially available, affordable desktop printers.

Diagnosis and medical training

3D printing of models affords further insights into pathological changes, as well as a visualisation of patient-specific organ anatomy. The education and surgical planning fields are two of the heaviest investors in 3D printing for the healthcare industry.

Leveraging additive manufacturing as a pre-operative planning tool has shown extremely promising results. The influx of organs required for transplant, particularly livers and kidneys, together with the scarcity of cadavers is increasing the need to use organs from healthy donors.

The aging population and rise of chronic diseases

Chronic conditions that are associated with later life, such as cancer, diabetes, arthritis, cardiovascular (CV) disease, Alzheimer’s disease, and Parkinson’s disease, are a challenge to healthcare systems.

According to the World Health Organization (WHO), there is a disproportionately greater prevalence of chronic, debilitating, and difficult-to-treat diseases in the elderly population. Cancer and CV disease occur more frequently in ages 70–75 years old, 80% of circulatory diseases occur in ages over 65 years, and the risk of developing dementia increases significantly after age 60 years (WHO, 1998).

There is a need for new treatments with reduced side effects and improved quality of life (QoL), leading to improved patient outcomes, reduced burden on primary care, and reduced hospitalisations. In addition, the aging population is leading to an increased demand for orthopaedic implants, and for spinal fusions.

Removing the need for animal testing

Traditionally, most new drugs, vaccines, and cosmetics undergo testing on animal models to ensure their efficacy and safety before human testing begins. These animals are typically specifically bred for testing and euthanised once the experiment has concluded.

3D bioprinting offers the potential to create functional, living, 3D human tissues of particular organs. These 3D tissues provide much more accurate mimicry to reality, resulting in much more predictive results for drug candidates, thereby reducing late-stage failures. Together with organ-on-chip devices, bioprinting is being implemented to create more robust in vitro models.

Partnerships

Since 2018, a large number of partnerships in 3D printing have been formed in the healthcare space to drive technology advancements and R&D. These include collaborations between other 3D printing companies, the biopharmaceutical industry, research institutes, and universities.

Biogelx and Regemat3D partnered to develop a new skin model and to offer complete bioprinting solutions for research institutes. Cellink and Volumetric Inc. co-developed the Lumen X Digital Light Processing (DLP) bioprinter to produce large vascular structures. 3D Systems and Collplant combined their technologies to generate artificial tissues and scaffolds.

In the biopharmaceutical space, recent collaborations include Aprecia Pharmaceuticals and Purdue University on 3D printed pharmaceuticals, and Poietis and the Assistance Publique – Hôpitaux de Marseille (APHM) on a Phase I clinical trial of a 4D bioprinted product for skin healing.

This is an edited extract from the 3D Printing in Healthcare – Thematic Research report produced by GlobalData Thematic Research.