Freeze drying is a crucial technique to prolong the shelf life of pharmaceutical products. Also known as lyophilisation, the technique stabilises and preserves sensitive products such as biologics, and diagnostic kits, in a permanently storable state.

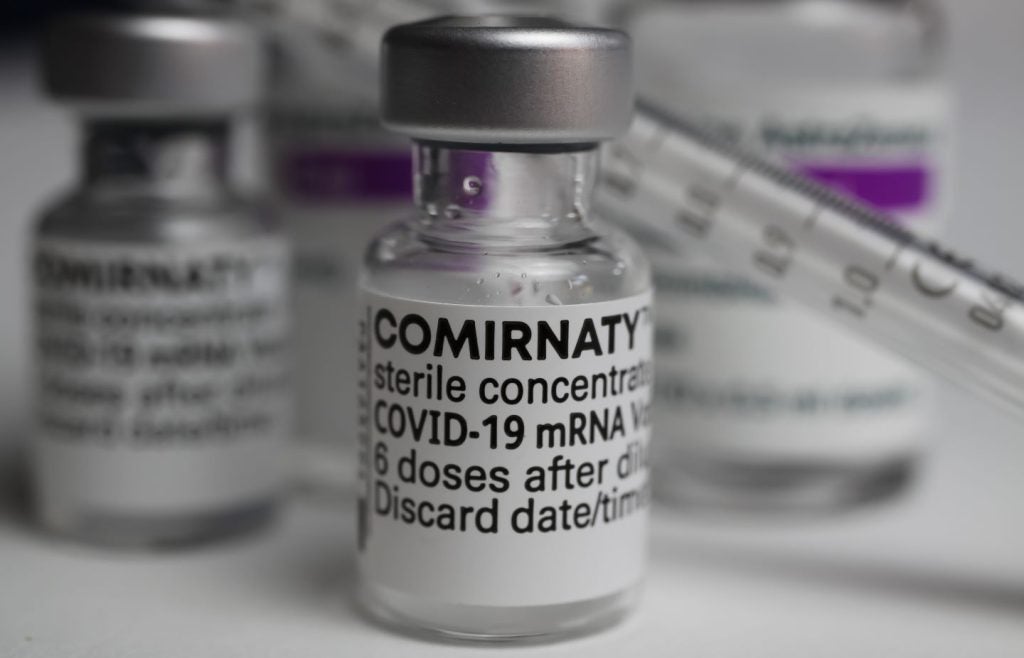

Pharmaceutical and biotechnology industries widely use freeze-drying systems to protect vaccines, antibodies, antibiotics such as penicillin, blood plasma, proteins, enzymes, hormones, viruses, and bacteria from heat and minimise their biological activity.

The pharmaceutical freeze-drying systems market is expected to be driven by the integration of smarter technologies in lyophilisation methods such as electron microscopy, biochemistry, and advancement in surgeries.

Discover the top freeze-drying systems companies for pharmaceuticals

Pharmaceutical Technology has listed some of the leading freeze drying systemscompanies based on its intel, insights, and decades of experience in the sector.

The list includes companies that offer freeze-drying products including, but not limited to, laboratory freeze dryers, industrial freeze dryers, nested vial systems, dry evaporators, concentrators, cold traps, glove boxes, freeze drying trays and shelves, glassware washers, water purification systems, and fume hoods. The list also includes manufacturers and suppliers of biological safety cabinets, clean benches, nanotechnology enclosures, drying chambers, vacuum pumps, filters, remote blowers and exhausters, loading and unloading systems as well as controlling and monitoring systems.

See Also:

The information contained within the download document is intended for pharmaceutical executives, sales managers, manufacturers, business development managers, technicians, freeze-dry operators, freeze-dryer market managers, refrigeration project engineers, packaging and inventory management associates, research associates, and any other individual involved in freeze drying in the pharmaceutical industry.

The document contains detailed information on the suppliers and their product offerings, alongside contact details to aid your purchasing decision.

Role of freeze-drying systems in the pharmaceutical industry

The pharmaceutical freeze-drying market is highly governed by stringent standards and laws. Freeze-drying systems companies help in the verification and validation monitoring of the freeze-drying process to comply with the latest regulations and good automated manufacturing practice (GAMP) guidelines. They offer security in pharmaceutical manufacturing by fulfilling the security rules such as process control settings and specific requirements for the collection of batch production and control records, based on which the pharma products should be produced.

The companies offer systems for more dynamic freeze-drying of products with more precision in control. They help in addressing any unforeseen fluctuations in process conditions and keep the manufacturers more informed during the process by sending prompt email notifications in case of an issue.

Advantages of pharmaceutical freeze drying

Pharmaceutical freeze-drying does not damage the physical structure of the product and allows delicate, unstable or heat-sensitive drugs and biologicals to be transported to longer distances and stored for a long period. The process eliminates the disadvantages of conventional drying methods or freezing.

Freeze-dried pharmaceutical products can be quickly reconstituted and are easy to use, making them suitable to be used as emergency vaccines and antibodies.