Italvacuum has recently introduced an innovative horizontal paddle dryer. Planex system, a multi-patented machine, is ideal for the most demanding operators, by guaranteeing results unavailable with conventional systems, both horizontal and vertical.

Designed to dry wet feed from filtration and centrifuging processes, the Planex system is suitable for the production of APIs, fine chemicals and intermediates.

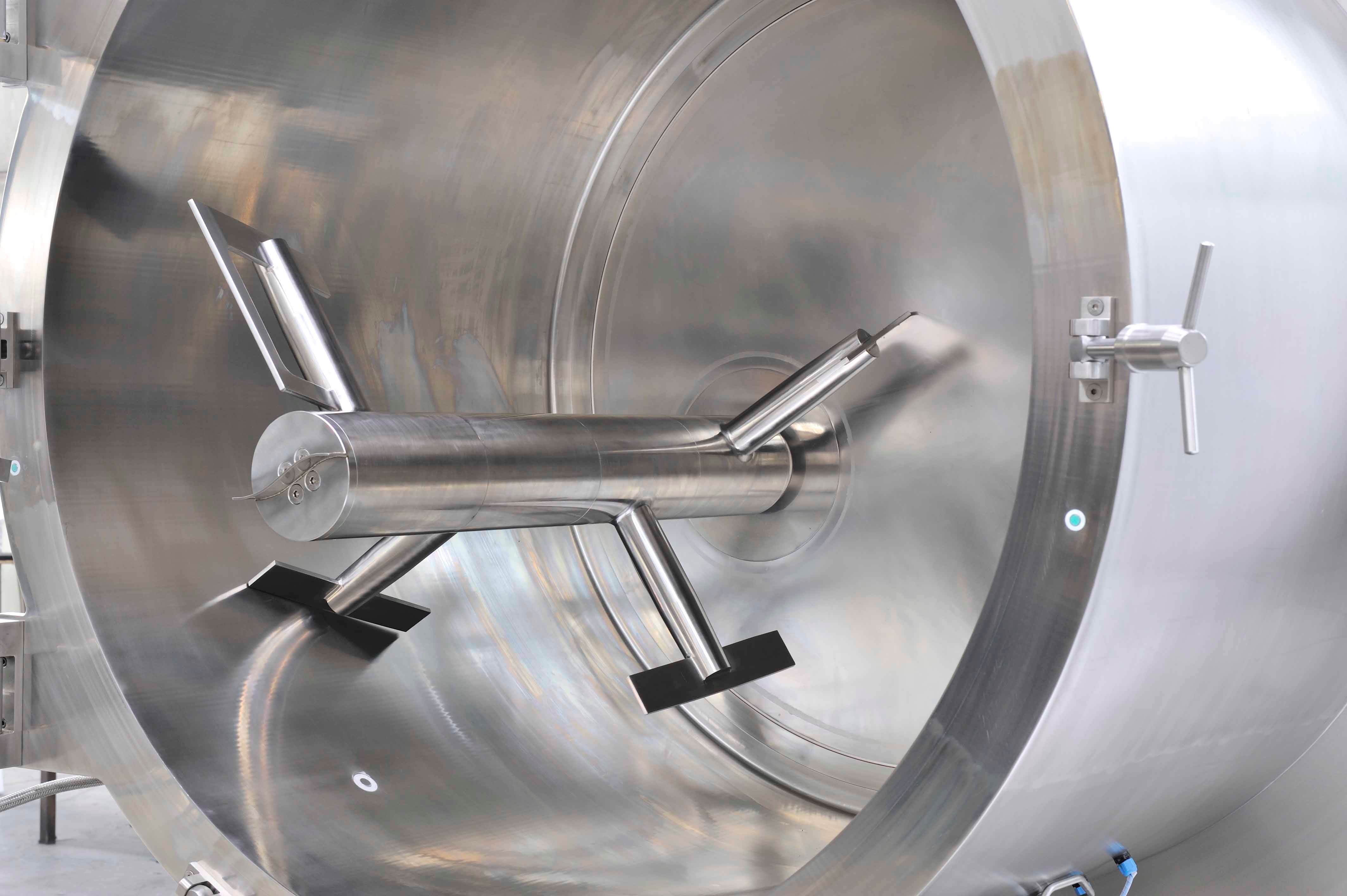

The added-value of the Planex system is the eccentric agitator with two independent movements that can simultaneously revolve around its own axis and rotate tangentially to the drying chamber.

Combined rotations of the agitator and its small size compared to the drying chamber diameter ensures the perfect mixing of the entire batch, and consumes at least three times less energy than conventional dryers with concentric agitators.

This means a threefold reduction in mechanical and thermal stresses on the batch being dried . As a result, even temperature-sensitive products are treated with maximum care.

The Planex system control software allows the user to automatically command the agitator movements with the Stop & Swing programme. The agitator swings back and forth, remaining immersed in the product, and guaranteeing continuous mixing. This approach is particularly effective when processing small batches.

In addition, the Planex system, due to its agitator’s ZeroFriction planetary movement, prevents the product from being rubbed against the drying chamber walls and heating up due to friction, a typical problem in conventional paddle systems.

The rotation of the paddles tangentially to the chamber walls conveys the product into the small clearance between the agitator and the chamber surface, preventing lumps from forming and guaranteeing effective drying and a controlled final particle size distribution, which is hard to achieve with conventional dryers.

The minimum clearance between agitator profile and chamber walls not only prevents product buildups, but also makes discharge significantly easier.

In addition, there is a specific automatic programme for the discharge operations. These operations are more effective due to the agitator ‘pendulum’ movement, which swings by 90° in the discharge area. As a result, the amount of product left in the chamber after discharge is minimal, averaging less than 1% of the volume.

Planex system features outstanding loading flexibility. The system is available with total volumes ranging from 150l to 3,200l. Maximum loading capacity depends on the product to be processed, and can vary from 15% to 80% of the chamber volume.

The system can meet all production needs of the pharmaceutical and chemical industries, as it is capable of processing small amounts of product, as well as large batches.

Planex system is safe for operators, the environment and the product because it is designed and manufactured in compliance with European Union ATEX directives and CE marking requirements, as well as US FDA standards and cGMP regulations.

Manufacturing materials

All parts that come into contact with the product are made of AISI 316L stainless steel, but other weldable materials such as Alloy C-22 and AISI 904L are available on request.

The drying chamber walls, agitator shaft and access hatch are heated by diathermal fluid circulation to prevent cold spots that can cause solvent condensation or product buildup.

Internal surfaces of the drying chamber are lapped or electropolished to optimise corrosion resistance, reduce adhesion and friction on the product, improve powder flow behaviour and facilitate cleaning operations.

The shaft of the agitator is complete with a double mechanical seal system, studied to guarantee the perfect vacuum tightness and the absolute purity of the dried batch, avoiding any risk of contamination of the product. The mechanical seal can be conventional type with wet flushing or run dry with nitrogen immission.

Ease of cleaning

All operations involved in washing the interior of the dryer, removing internal parts, inspecting the unit and cleaning the exterior are simple and straightforward.

Internal washing

The fully accessible chamber interior, with no hard-to-reach zones, ensures the entire dryer can be perfectly cleaned. To make the washing operation even more effective, the dryer is equipped with an efficient CIP system with retractable rotating washing head.

This also provides significant savings as the agitator’s off-centred position enables it to rotate during washing, reducing the amount of liquid needed.

Internal parts removal

Due to its special structure, the agitator can be readily disassembled into removable sectors, making cleaning operations even more effective. This is an exclusive feature that makes Planex system a one-of-a-kind dryer.

In conventional systems, the agitator is made of a single structure and removing it requires the use of bulky equipment and long system downtimes.

Internal inspection

The big front-opening hatch provides full access to the entire drying chamber. Other advantages include the agitator’s off-centred position. This allows the operator to have more room to work, making it faster and easier to carry out swab testing.

External cleaning

The exterior of the Planex system is also easy to clean. The entire machine is housed in a sealed external casing (cGMP particle-free configuration), which encloses the insulation and all electrical, hydraulic and pneumatic circuits.

In addition, no support to the machine is present in the clean room, as the drying chamber is flange-mounted on the wall. In this way, the chamber exterior can be cleaned quickly and effectively, avoiding product accumulations in slots or junctions.

These features, combined with the partitioning approach, permit clean room installation, so the clean area can be pressurised and kept separate from the technical area.

Pilot trials

In its factory Italvacuum has a Planex system pilot, which allows it to conduct drying tests.

1 Analysis by Politecnico di Torino’s Department of Materials Science and Chemical Engineering