Next-Generation SCHOTT EVERIC™ Vials

Each drug formulation is unique, as is every patient. Especially high-potency medicines breaking into the market have exacting pharma packaging must guarantee drug stability.

With every drug requiring specific packaging features, pharma companies are looking for a concept that combines established packaging standards and a modern approach.

The filling process

Traditional fill and finish operations rely on bulk filling lines. While these allow for high throughput in a short period, the pharmaceutical containers are exposed to direct glass-to-glass contact. Subsequently, this can create glass particles that may end up inside the container or lead to defects and glass breakage.

On top of this, developing and producing highly potent drugs such as biologics or vaccines comes at a high price. The need to reduce possible glass breakage and to increase yields at the same time is, therefore, putting additional pressure on the pharmaceutical filling process.

External impact

Although glass has a remarkably high natural strength, the risk of breakage increases when pre-damaged glass faces mechanical load. On conventional bulk filling lines, containers are exposed to axial and side pressure, for example, when they encounter glass-to-glass contact with other vials or glass-to-metal contact between the vials and the filling machine. These situations may lead to scratches or cracks, which can result in glass breakage.

Climbing effect

Although glass has a remarkably high natural strength, the risk of breakage increases when pre-damaged glass faces mechanical load. On conventional bulk filling lines, containers are exposed to axial and side pressure, for example, when they encounter glass-to-glass contact with other vials or glass-to-metal contact between the vials and the filling machine. These situations may lead to scratches or cracks, which can result in glass breakage.

As vials come into direct contact with one another, the containers may stick together or begin climbing upwards. Both scenarios increase the risk of creating waste.

Risk of drug/container interactions

As a majority of sensitive and biologic drugs are filled below nominal filling volume, the risk increases of the drug interacting with the container. This happens as the bottom-near heel region of standard vials may acquire an inhomogeneous chemical structure during the forming process and is prone to ion exchange. In other words: A lower filling volume is met with a higher amount of leachables from the container, which may harm the drug and reduce drug stability.

Multiple needs, one solution

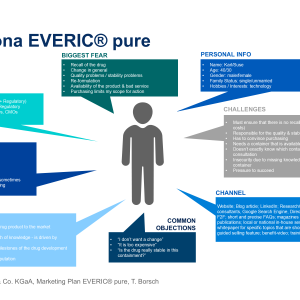

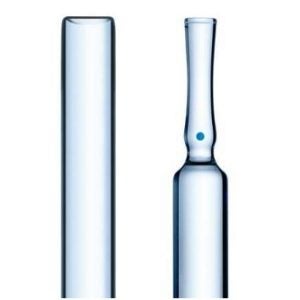

In order to meet the various exacting demands of sensitive drugs and drugs with low filling volumes, SCHOTT developed a modular vial concept known as SCHOTT EVERIC. Manufactured from an improved FIOLAX borosilicate glass tubing, namely FIOLAX CHR (controlled hydrolytic resistance), the ultra-pure vials offer a packaging solution that serves individual drug and patient needs.

The story behind EVERIC™

Dr Robert Frost, Dr Florian Maurer and Stephanie Mangold from the development team present key features from EVERIC and share insights about why drugs of the 21st century benefit from a modular primary packaging set-up.

For a healthy future

Health plays a vital role in society and as novel drugs and treatment options are being developed, requirements for the drug packaging will only become more complex. Whether it is to protect the drug formulation or to improve the patient experience, an extended EVERIC vial portfolio including, for example, an inner coating for enhanced drug stability will ensure that all needs – both from the drug and the patient – are covered.

For more information, please fill out the enquiry form attached to this page.