Atlantic Coast Crushers is a specialist manufacturer of machinery that shatters and disintegrates agglomerations, including chunks and lumps formed from friable materials. We manufacture a wide range of size reduction machinery, including crushers, lump breakers, granulators, pulverizers and comminutors for the pharmaceutical industries. Whilst we stock default machinery, the varied requirements of our customers means that we continuously produce original client-orientated designs and / or modifications of our standard equipment for precise usages and processes.

The breaking down of oversize substances to a steady, regular free-flowing size eliminates possible line blockages in advance, so ensuring that product transport equipment can run at maximum efficiency. Crushing and lump breaking also increases the available surface area of materials, allowing reactive procedures, such as dissolving, mixing and melting, to occur with greater speed and effectiveness.

The following equipment designs outline our standard machinery, but we can accommodate many other special requirements.

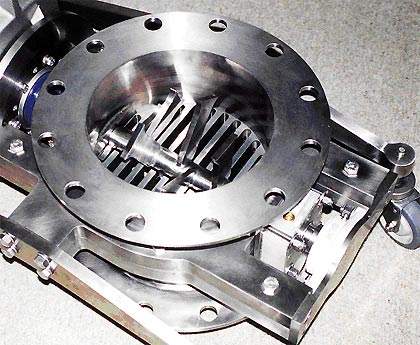

ROTATING BLADE CRUSHING DEVICE

The Flow-Sentry is a fully enclosed crushing device that exercises a single set of rotating blades to impact and shatter at close range any large lumps or chunks of material as they travel through the impact area of the machine. Ideal for protecting pumps or preventing clogs in pressurized piping systems, the patented design of the Flow-Sentry allows us to offer the machine with most common flange styles, i.e. ANSI or DIN Pipe Flanges, sanitary ferrules, etc., with custom fabricated shapes or with our very short face-to-face ‘wafer’ design, for easy integration into existing installations. It can also be incorporated into the inlets or outlets of reactor vessels, storage silos, bulk bag unloaders, or other similar locations.

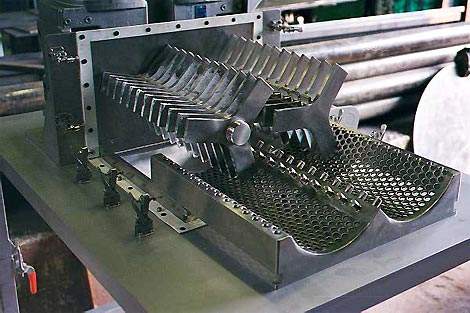

HEAVY DUTY LUMP BREAKER

Flow-Smasher Crushers are heavy duty, high torque, low-speed and high capacity machines, which are capable of breaking down oversize solids to produce consistent, free-flowing material. The Flow-Smasher is available in numerous sizes and with several different blade/shaft configurations, including the ‘Brick-Breaker’, ‘Hedgehog’ and ‘Bear-Claw’ designs, which allow us to break down a variety of troublesome materials. This machine can be made to be suitable for sanitary applications and can be made in a variety of exotic materials of construction.

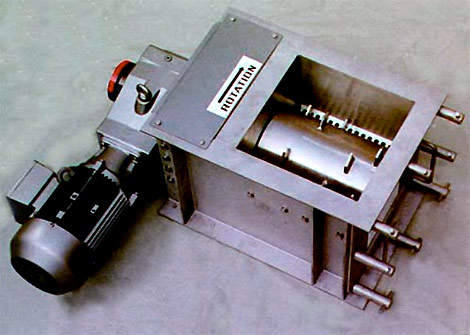

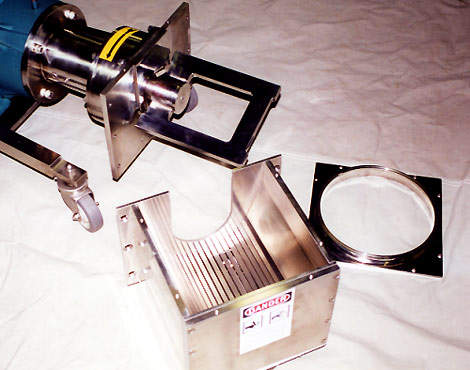

LUMP BREAKER FOR DRY BULK MATERIALS

The Flow-Sizer is an economical, heavy-duty medium speed crusher designed to reduce dry bulk materials to a consistent, fine, free-flowing size. The Flow-Sizer’s dynamic crushing action shatters and disperses troublesome oversize materials. The short blades allow for a powerful and effectual crushing action, producing a fine output size at high capacity. Standard inlet sizes are readily available, up to 12in x 48in, with additional custom sizes and materials as required. This machine can be made to be suitable for sanitary applications and can be made in a variety of exotic materials of construction.

HIGH-SPEED ROTARY CUTTER FOR FINE GRINDING

The Particle-Sizer is a compact device with a high output capacity that can be used to reduce large chunks or lumps of dry bulk solids to a fine powder. The Particle-Sizer uses a high-speed rotary cutter to sweep the solids past a series of sharp stationary cutter bars mounted in a ‘Sizing Cage’. The Particle-Sizer can be used by itself with moderately oversize materials or in combination with one of our other crusher designs for very large chunks, and optional cutter designs and cage sizes allow for output size adjustability. This machine can be made to be suitable for sanitary applications and can be made in a variety of exotic materials of construction.

See also Chemicals Technology – Atlantic Coast Crushers – Crushers and Lumpbreakers