West Pharmaceutical Services has long been a reference point in primary packaging for injectable therapies. Its latest launch—the West Synchrony™ prefillable syringe (PFS) system—has won the Product Launches award in the Prefillable Syringe Systems category in the 2025 Pharmaceutical Technology Excellence Awards.

West Pharmaceutical Services won the award for introducing an integrated, data-driven syringe platform that simplifies development, strengthens supply reliability, and better supports the complex requirements of biologics and vaccines. The recognition reflects how West has moved beyond a component-by-component mindset to deliver a fully verified, system-level platform that is designed for the specific needs of today’s biologics and vaccine pipelines.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

“Leaders in drug development face pressures to meet milestones efficiently amid complex challenges, amongst them, selecting prefillable syringes. They currently rely on fragmented approaches—assembling component data from multiple suppliers or outsourcing piecemeal verification, which risks delays, increased costs and regulatory setbacks,” said Andy Polywacz, President of Integrated Systems at West. “With West Synchrony prefillable syringe system, it enables pharmaceutical companies to streamline design, accelerate regulatory submission, and secures a reliable supply chain for combination products that meets quality and volume needs.”

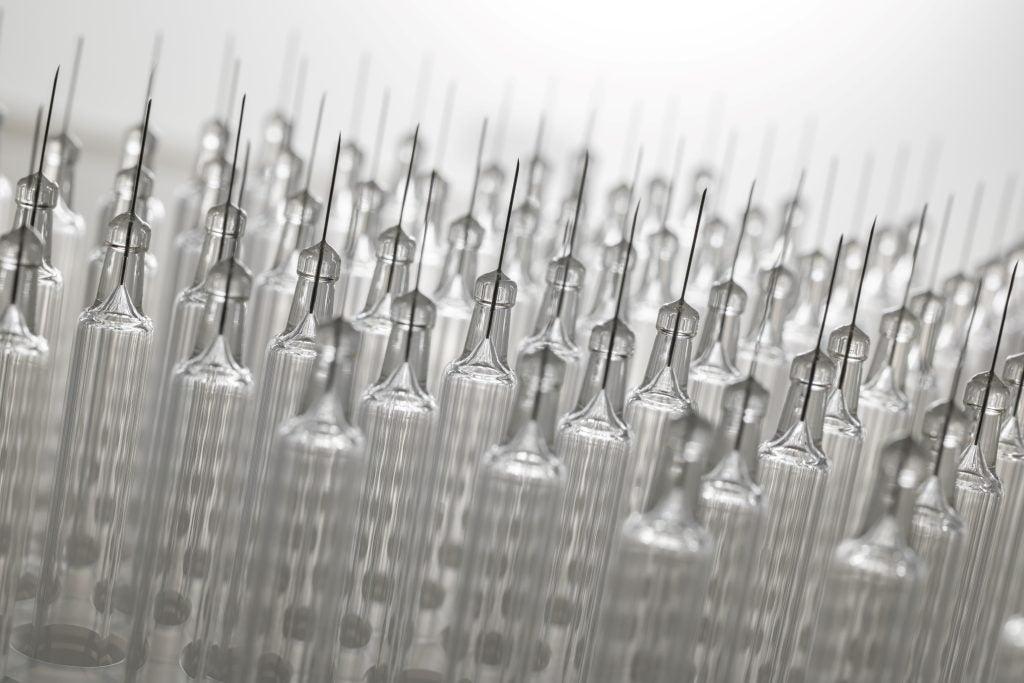

A fully integrated prefillable syringe system for biologics and vaccines

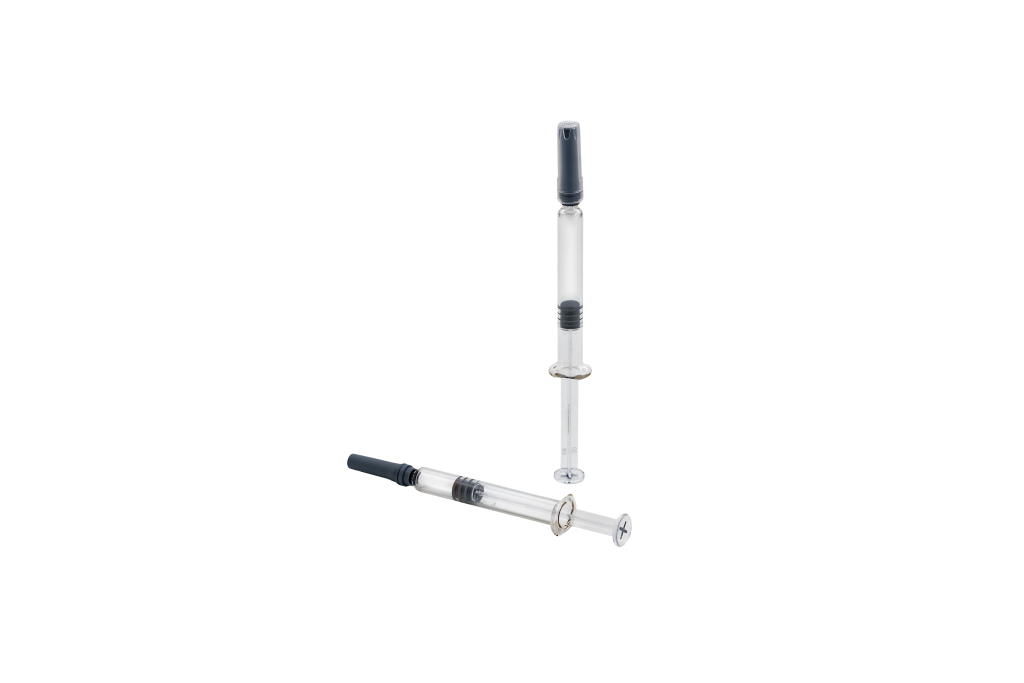

At the core of the award is West’s shift from supplying individual components to offering a harmonized PFS system. The West Synchrony PFS system integrates the syringe barrel, plunger, and needle shield or tip cap into a design-verified configuration, sourced entirely from one supplier. This moves the focus from assembling parts to deploying a single, engineered system that has been designed and verified for form, fit, and function as a whole.

That distinction matters for biologics and vaccines, which are often more viscous, more sensitive to contact materials, and more demanding in terms of container closure integrity (CCI) than traditional small-molecule injectables. In such cases, minor variability in glide force, dead volume, or sealing performance can translate into meaningful risk for dose accuracy, device performance, or product stability. When different elements—such as glass syringe barrels, plungers, and needle shields—come from multiple vendors, these interactions have to be characterized and managed by the drug developer, adding complexity and uncertainty.

The West Synchrony system is designed to reduce much of that burden. Instead of requiring drug developers to create custom assemblies and then demonstrate that the combination performs adequately, West provides a single design verification and characterization package that covers the entire syringe system. The system-level data demonstrate how the integrated barrel, plunger, and needle shield or tip cap behave together, rather than as isolated components. For development teams, this means they are not starting from a blank slate with each new project; they can work with a configuration that has already been tested as a complete device constituent part.

This approach is particularly relevant for combination products and for delivery via autoinjectors, where consistency in break loose and glide forces is critical to predictable device performance. By supplying a harmonized system instead of a set of parts that need to be matched and revalidated, the West Synchrony platform helps reduce the technical and operational risks associated with integrating multiple suppliers. The single-supplier model also consolidates accountability for performance, quality, and change control at the system level, which is increasingly important as biologics and vaccines become more central to pharmaceutical pipelines.

Data-led development and streamlined regulatory pathways

A further factor behind the award is the way the West Synchrony S1 PFS system translates technical integration into gains in development efficiency and regulatory clarity. The platform is built around the idea that PFS component selection should be supported by robust data, rather than relying on extended trial-and-error evaluations. To that end, West provides a comprehensive, system-level verification data package. Additionally, the system is filed under single drug master file and has a unified regulator package to supper non-DMF regions, which consolidates the documentation covering the full PFS configuration.

This unified package is intended to simplify a process that has traditionally been fragmented. When different components come from different suppliers, development and regulatory teams must assemble data sets from multiple sources, reconcile different formats, and assess how changes on one component might affect the overall system. With West Synchrony, the verification and regulatory information is aligned to the complete syringe system from the outset, which allows teams to make decisions based on an integrated performance profile.

In practical terms, this helps compress timelines on multiple fronts. During early development, teams can narrow options using existing performance data rather than commissioning extensive, bespoke testing for every configuration change. When moving toward clinical or commercial stages, regulatory affairs teams can work from a single, harmonized dossier instead of compiling and reconciling multiple files, each with its own structure and change-control practices. This reduces the number of interfaces and handoffs that can introduce delay or uncertainty.

The platform is also structured to support continuity across the product life cycle. The same system-level data and regulatory foundation underpin key stages of a typical development journey: scouting and evaluation, technology transfer, engineering and clinical runs, and preparation for market readiness. During scouting, information packages enable an early assessment of fit without requiring a full custom program. As programs advance, the same system and data carry through to FlexQTY™ and StdQTY™ supply.

A single letter of authorization and a single point of contact further reduce friction as sponsors move through these stages. Instead of re-negotiating relationships and documentation frameworks with multiple component suppliers as they scale up, drug companies can maintain one consistent system architecture and regulatory reference. For combination products, which already involve coordination between drug, device, and often delivery software, this consolidation helps limit the risk of late-stage changes, additional file work, or re-architecture of submissions that can affect launch timing.

Scalable, quality-focused supply that protects sensitive molecules

The West Synchrony S1 PFS system also stands out for how it connects technical performance with scalable supply and quality controls. On the supply side, West has structured the offering around FlexQTY and StdQTY pathways that align with clinical and commercial milestones. FlexQTY batches are intended for early development and clinical testing, offering low minimum order quantities while maintaining the same verified system attributes as larger runs. This allows drug developers to conduct drug-dependent testing and early clinical work without committing to commercial-scale volumes or altering the underlying syringe system.

As programs progress, sponsors can transition to StdQTY volumes designed for broader clinical and commercial needs. These larger quantities are based on the same nested tub formats and system configuration as FlexQTY, so the move from smaller to larger batches does not introduce a new syringe design that would require additional validation or changes to regulatory files. For example, the standard 1 ml long prefillable syringe format is offered in both FlexQTY and StdQTY, with consistent system components and performance characteristics across order sizes. This continuity supports planning, reduces scheduling friction with contract manufacturers, and helps limit the need for repeated qualification work as volumes increase.

Within the West Synchrony S1 PFS system, high-performance plungers are a core element of the design. All plungers available in the system undergo West’s Envision™ verification process, which is used to proactively screen for defects, contamination, and particulates. This inspection step is applied systematically, reflecting growing expectations around particulate control in injectable products. By integrating this level of verification into the standard offering, the platform aims to reduce quality variability at scale.

Plunger options include West NovaPure® and FluroTec(TM) barrier film plungers, as well as other plungers equipped with FluroTec™ barrier film. These are configured into the system to deliver low and tightly controlled break loose and glide forces, parameters that are important for consistent injection behavior and for compatibility with leading autoinjector platforms. Consistent break look and glide force profiles can help support reliable device actuation and dosing, especially for higher-viscosity biologic formulations where variations in forces can be more pronounced.

From a drug product perspective, the system incorporates barrier film technologies such as FluroTec to help protect sensitive molecules. The FluroTec film acts as an effective barrier between the drug and the elastomeric plunger surface, minimizing direct contact and thereby helping to reduce the risk of chemical interaction, adsorption, and absorption. In doing so, it supports container closure integrity and contributes to maintaining drug stability over time, issues that are particularly relevant for biologics and vaccines.

The combination of proactive particulate control, reliable break loose and glide force performance, and barrier properties is aligned with the quality expectations associated with advanced injectable therapies. Furthermore, the configuration options available within the West Synchrony S1 PFS system allow companies to leverage these attributes across a range of formats. High-demand presentations – such as 1 ml long and 2.25 ml staked needle syringes with commonly used gauges, thin wall or special thin wall needles, and small round flanges – are available on a make-to-stock basis, enabling relatively rapid readiness for launch or scale-up where these formats are appropriate.

Alongside these standard offerings, a broad make-to-order catalogue provides additional flexibility. Options include different needle gauges and lengths (for example, regular wall, thin wall, and special thin wall variants), flange geometries (small round, large round, or cut flanges), luer lock versions for both 1 ml and 2.25 ml formats, and multiple plunger constructions, including unlaminated and barrier film variants. These configurations are all delivered within the same overarching system architecture and regulatory framework. As a result, pharmaceutical companies can align drug delivery characteristics with the needs of specific molecules, devices, or administration routes, while staying within a standardized, system-level platform that has already been characterized and documented.

Company Profile

West Pharmaceutical Services, Inc. is a leading provider of innovative, high-quality injectable solutions and services. As a trusted partner to established and emerging drug developers, West helps ensure the safe, effective containment and delivery of life-saving and life-enhancing medicines for patients. With over 10,000 team members across 50 sites including 25 manufacturing facilities worldwide, West helps support our customers by delivering over 41 billion components and devices each year.

Synchrony, NovaPure, FluroTec, Envision, StdQTY, and FlexQTY are trademarks or registered trademarks of West Pharmaceutical Services, Inc. FluroTec technology is licensed from Daikyo Seiko, Ltd.

Contact Details

Chris Gross, Director, Business Development

Katie Falcone, Director, Technical Services

Links

Website: www.westpharma.com