The University of Nottingham in the UK has announced the development of a new method enabling the creation of 3D-printed personalised pills.

The innovative technology has been developed by scientists from the university’s Centre for Additive Manufacturing and its Schools of Pharmacy and Life Sciences.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

The technique utilises multi-material inkjet 3D printing to produce tablets with personalised drug release profiles, which can release drugs at a controlled rate.

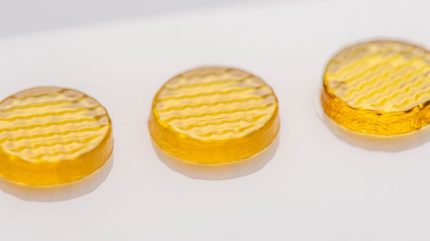

It leverages a unique ink formulation based on molecules sensitive to ultraviolet light. Upon printing, these molecules form a water-soluble structure.

The interior structure of the tablet is intricately designed to time the dosage release precisely.

Assistant Professor Dr Yinfeng He of the University of Nottingham’s Faculty of Engineering’s Centre for Additive Manufacturing stated: “This is an exciting step forward in the development of personalised medication.

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalData“This breakthrough not only highlights the potential of 3D printing in revolutionising drug delivery but also opens up new avenues for the development of next-generation personalised medicines.”

The advancement is significant as it prints multiple drugs into a single tablet, streamlining complex medication regimens into one dose.

This approach could be advantageous for developing medications that require timed drug release – critical for treating certain diseases.

The potential for scalability of the approach was demonstrated by the ability to print 56 pills in a single batch.

Professor Felicity Rose of the University of Nottingham’s School of Pharmacy stated: “The future of prescribed medication lies in a personalised approach. We know that up to 50% of people in the UK alone don’t take their medicines correctly and this has an impact on poorer health outcomes with conditions not being controlled or properly treated.

“A single pill approach would simplify taking multiple medications at different times and this research is an exciting step towards that.”