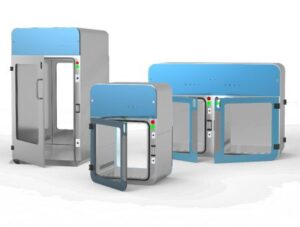

Concept Modular Cleanrooms

Metisafe’s pre-engineered unique approach to building modular cleanrooms comprises over 100 models that are suitable for installation in pharmaceutical production facilities.

Instrument concept modular cleanrooms

The units’ steel structure provides strong, self-standing, leak-proof panel connections. They are quickly assembled on-site, and consistently achieve high-performance indicators without any intervention.

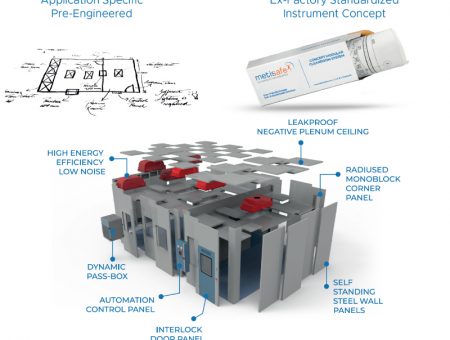

Application-specific modular design concept ensures that its units contain independently controlled HEPA fans, optimized airflow, negative plenum designs and self-standing steel structures, along with automation-controlled critical areas and facility-independent box-in-box layouts.

The systems need only an electric power source and chilled water supply for positive pressure rooms and additional exhaust duct outlet localization for negative pressure rooms. They also feature an improved warning system that notifies improper operation.

Reduction of operational costs

The units have a low maintenance cost, are optimized for energy use and have decreased annual validation costs. Their total investment and operational costs are lower than conventional cleanrooms.

Options include pre-engineered modifications, pre-assembled integrated laminar flow (LAF) units, sinks, fire alarm sensors and building management system (BMS) integration.

Negative plenum recirculation ducts for pharmaceutical cleanroom particle sweeping

Metisafe uses the negative plenum concept in its cleanroom designs to increase particle-sweeping efficiency in pre-engineered recirculation ducts and prevent particle leaking.

The units feature homogenous temperature distribution, which enhances safety and conformity performance during operation. They also save energy and provide active noise control.

Modular airflow instrumentation for cleanrooms

Metisafe’s portfolio of cleanroom equipment includes self-standing steel wall and rounded corner panels, HEPA fan units, interlock doors, pass-boxes, automation control panels, illuminations and ultraviolet (UV) lamp armatures, as well as other cleanroom parts and controlled environment equipment.