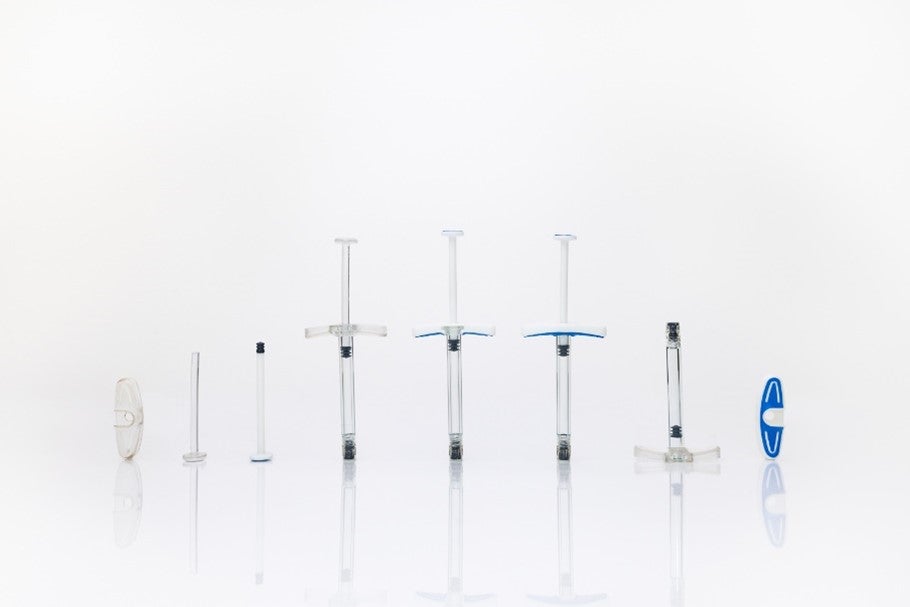

Pre-Filled Syringes with Better and Safer Handling

Making syringes safer to use for all parties involved is one of the Sanner Group’s intentions when developing and manufacturing finger rest extensions and plunger rods. Oncology medicine must be easy to administer for doctors; insulin should be easy to use in self-administration for all patients; and aesthetic medicine also does not forgive the slightest safety flaw in administration. However, there are subtle differences in the different industries, which require a stronger individualization of pre-filled syringes. Hence, it is advisable for pharmaceutical producers to combine their glass or plastic syringes with individually adapted components, which increase not only customer and patient orientation but, above all, safe usage. All these different requirements can be met with a simple recipe: individualization.

Therefore, a contract design and manufacturing partner like Sanner offers you multiple solutions. As far as safety and handling aspects are concerned, the design of individualized syringe components focuses on ergonomics. However, optics also play an important role: while end users, especially in the aesthetic field, prefer to undergo their expensive treatment by means of a high-quality and visually appealing device, pharmaceutical companies primarily want to set their products apart and gain a competitive advantage. They can apply the brand name or logo, use different colours or indicate dosage strengths. Moreover, regional traceability, safety, and information requirements can be met with simple but effective means.

The Sanner Idea-Design-Product Process® which is a standardized stage-gate process for device development is starting from concept and design generation up to prototyping and industrialization. Prototypes for example can easily be done with additive-manufactured tool inserts. Here you get your syringe accessory already in the final material for testing.

Thanks to our usability engineering, we also manufacture piston rods and finger rest enlargements using two-component injection moulding (TPE) in the smallest shot weights for better grip and even more safety during the injection. The ability to rotate the syringe barrel in the support enlargement allows the syringe needle to be optimally aligned, so the syringe does not have to be applied several times.

Sanner is manufacturing plastic syringes in accordance with GMP, also in a class 8 clean room, and are DIN EN ISO 13485 and DIN EN ISO 15378 certified. 100% traceability through integrated ME systems are standard. The professional and experienced production of the plastic syringes in the injection moulding process ensures precise dimensions, perfect concentricity and an even surface structure for an optimal print image as well as siliconisation.

Our engineering team and our product design implements your existing plastic syringe concept or develops a new one that is tailored to the current requirements of the pharmaceutical industry and the filling systems.

Find out more about the options to make your pre-filled syringes safe and convenient.