EMD Serono, a wholly owned subsidiary of Merck KGaA, which is based in Darmstadt, Germany, launched a new research facility in Billerica, Massachusetts, US, in February 2011.

The $65m project, constructed over a period of three years, is Merck’s fourth R&D centre. Merck also operates three research centres in Germany, Switzerland and China.

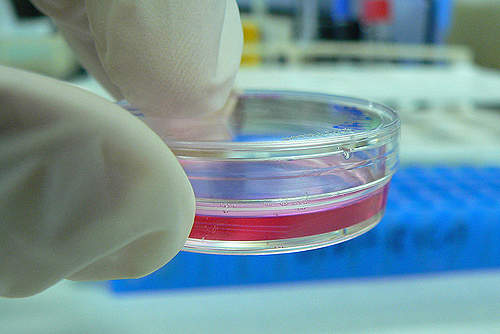

The new Billerica facility will operate with 200 scientists who have proven skills in cancer biology, cancer immunotherapy, oncogene signalling, medicinal chemistry, molecular modelling, protein engineering, therapeutic antibodies and manufacturing cell lines across the key therapeutic areas of neurodegenerative diseases, cancer and infertility.

The expansion resulted in approximately 100 jobs in Massachusetts.

In April 2011, the facility received Leadership in Energy and Environmental Design (LEED) certification at gold level for five categories including indoor environment quality, sustainable sites, water efficiency, energy and atmosphere, and materials and resources.

It is the sixth LEED Gold certified laboratory in Massachusetts and is one of 89 facilities across the US that have been recognised with LEED GOLD certification. It has also been verified by the Green Building Certification Institute (GBCI).

EMD Serono project

The EMD Serono project involved structural upgrades and improvements to an existing building as well as expanding the campus footprint with a new ground up construction.

During construction, a 54,000ft² fully operational laboratory remained connected to the new facility.

Billerica facility

EMD Serono’s Billerica facility spans 140,000ft² over a 225 acre parcel of land that also houses an R&D building and a protein production laboratory, which were constructed in 2003. It includes more than 115,000ft² dedicated to laboratories and offices.

Approximately 25,000ft² is allocated to chemistry and screening laboratories. Biology and cell culture laboratories occupy 25,000ft² and nearly 22,000ft² is for general laboratory support purposes. Offices and conference rooms together constitute 20,000ft². The facility also includes approximately 23,000ft² of mechanical space.

A 25,000ft² central node area houses a reception zone, a fitness centre, a cafeteria / auditorium with a capacity for 225 people, as well as additional offices and conferences rooms.

Contractors

EMD Sereno employed several Massachusetts-based contractors for the project. The contract for the management of the facility’s construction was awarded to Jones Lang LaSalle.

The contractor constructed the facility in 370,000 man hours with no lost time and recorded injuries.

Ellenzweig was the architect for the Billerica project. The company provided programming, site planning, laboratory planning, design and construction administration services. Other contractors involved in the project include consulting engineer BR+A, LLC, which provided mechanical engineering services, and BSC Group, which was the civil engineer.

The geotechnical engineer for the project was GEI, which provided site planning and design services.

Production

The EMD Sereno research facility will be dedicated for the discovery and development of novel treatments in areas of oncology, neurodegenerative diseases and infertility.

Sustainable features

The facility’s design includes several environment friendly features and was designed to consume 19% less energy and 72% less water compared with similar buildings.

The facility has energy-saving cooling towers, high efficiency boilers and variable speed chillers, low flow fume hoods, low velocity / pressure drop, energy saving air distribution systems, lighting and controls, exhaust energy recovery systems and a low flow water system.

To maximise natural daylight, solar panels were installed throughout the facility to generate electrical energy for the lobby zone.

A daylight monitoring system ensures minimum usage of electricity.

Over 20% of the facility was constructed with recycled materials. Approximately 95% of the construction waste, including brick and steel content, was recycled. Nearly 50% of the wood used for the facility is certified by the Forest Stewardship Council.