Boehringer Ingelheim officially opened the new active ingredients plant in Ingelheim in early 2003. The plant will be able to produce over 20 different active ingredients, which require over 100 production steps. The company already has existing production facilities in Ingelheim, where products covering respiratory diseases and diseases of the central nervous system are manufactured.

The new multi-purpose facility will be able to produce up to 1,000t of active pharmaceutical ingredients (API) per year. The plant will be able to offer a wide range of organic synthesis operations, phytochemical extraction and derivatisation in addition to a wide range of purification methods including crystallisation, chromatography, extraction and distillation.

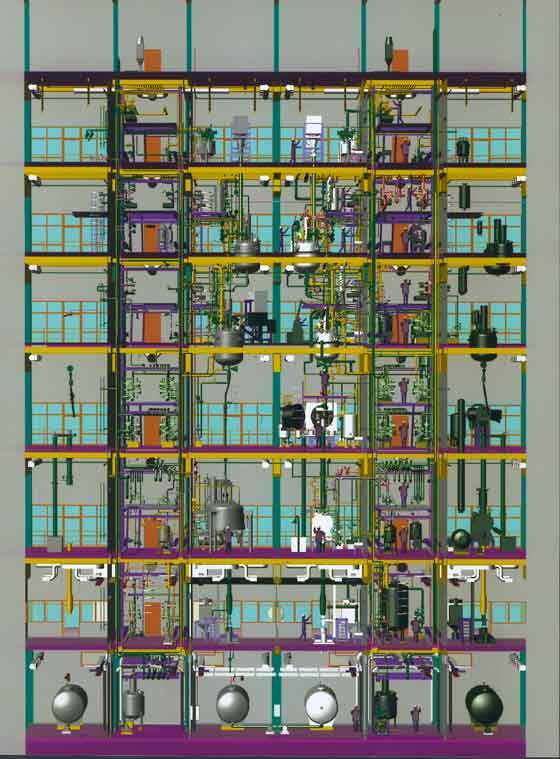

PLANT CONSTRUCTION

Construction of the new development began in June 1999 and was expected to be ready for inspection and approval by the regulatory authorities by December 2001, with production due to start in early 2002. The actual time-scale was a little behind schedule with the plant opened and at full production early in 2003.

The initial investment of €180 million ($168 million) in the new plant is one of the largest investments made in the company’s history. The new plant has replaced the outdated synthesis Plants 2 and 3 at the Ingelheim site. These two plants have been cut back in terms of production output and will be phased out when the new plant has proved it can meet its production targets. It is intended that the production processes in the Boehringer’s Special Products Plant (BfS) will also be transferred to the new plant in due course.

LURGI OEL GAS CHEMIE

Lurgi Oel Gas Chemie won the construction contract for the new plant in April 1999. The contract included the design, the building of the plant and purchase, qualification, assembly and validation of the equipment.

The basic engineering was agreed before Lurgi became involved. This included the precise details of the plant, such as the design and circuiting of equipment, pipelines and automation solutions. An agreement covering this work was signed in December 1997. This phase revealed the enormous complexity of the project and the fact that the costs incurred were considerably higher than originally planned.

CONSTRUCTION

The 49m-high plant was originally designed to comprise nine synthesis sections to be built with additional laboratory and social amenity buildings. The APIs produced will be used in Ingelheim as well as other Boehringer plants around the world. The plant was originally supposed to include nine synthesis bays, but due to cost overruns only six were built, with provision being left for the other six in a future expansion. Building the remaining three wings will depend on several factors which will include new developments from Boehringer Ingelheim R&D and successful positioning in the market.

FACILITIES FOR ORGANIC SYNTHESIS

The facility has four plants for organic synthesis, which include 90 glass-lined and stainless steel reactors totalling 178m³ (capacities ranging from 0.5m³ to 6m³). There are three bromination reactors, one cyanobromination facility, 15 hydrogenation units (pressures from 6bar to 150bar). The reactors can carry out reactions over a temperature range of -70°C to 250°C. The processing facilities include four rectification columns, 35 dryers, 30 centrifuges of various types and a tankfarm for solvent storage.

FACILITES FOR PHYTOCHEMICAL PROCESSING

There are two extraction plants for herbs (volumes of vessels 3m³ and 6m³). In addition, there are 16 glass-lined and stainless steel reactors of volumes ranging from 500 to 2,000 litres. There are also ten crystallisers, high vacuum distillation apparatus, a Robinson-Schöpf condensing plant and five liquid-liquid extraction plants. The facilities are able to process quantities from a few kilograms to several tonnes of material.

SIGNIFICANCE OF NEW PLANT

The significance of the project is clear when considering that the new plant will produce the active ingredients for pharmaceuticals which together will account for almost half the corporation’s total world sales. The location of the new site also means that the existing Ingelheim site will continue to play a key role in the production of drug substances in the long term. The plant will play a central role in providing Boehringer-Ingelheim’s European network of process and finishing plants supplied with the raw active pharmaceutical ingredients it needs to fulfil its production commitments.

FINANCE

The company signed a loan agreement with the European Investment Bank (EIB) to help finance the construction of the new plant. The loan is worth €100 million ($94 million) and is brokered via a German bank. The European Investment Bank’s aim in granting the loan was to promote European industry in a key high technology and potentially high growth industry against a background of market globalisation.