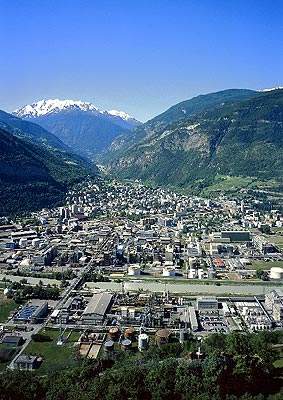

Lonza Biotec completed the construction of new manufacturing capacity with a multi-product design at Visp in Switzerland in mid-2005. Work on the site had commenced in March 2003. The capacity expansion was for the production of biopharmaceuticals using microbial fermentation and also for the production of recombinant vaccines. The facility houses two separate fermentation and downstream processing lines that are fully validated for cGMP manufacture of biologics.

The plant was designed to allow a modular addition of further equipment when deemed necessary. The facility was built and equipped in two phases. The first phase involved the construction of a small-scale 1,500l reactor and processing stream, which was operational by November 2003. The second phase included two 15,000l reactors, which were constructed alongside phase one and became operational by the end of the first quarter of 2005 and the second half of 2006, respectively.

The initial investment by Lonza was CHF100m. In September 2004 Lonza also started up a cGMP (current Good Manufacturing Practice) single train 1,000l bioreactor with primary product recovery and protein purification facilities that required an investment of CHF30m. This expansion project was started construction in 2003 as a response to a demand for additional capacity for production of recombinant vaccines by fermentation.

Visp small-scale production plant

The Visp site has also undergone extensive refurbishment and expansion of its process research and development facilities; this was completed by the last quarter of 2003. Lonza announced in June 2003 that it was ready to bring on-line a new small-scale production plant at the Visp site, to enable the company to expand its operations in the chemical manufacturing of pharmaceutical products.

The plant was designed for the production of quantities from 10kg to 150kg and closes the gap between the production capabilities for laboratory use and commercial-scale manufacture, allowing it “to support the whole life cycle of pharmaceutical products, from pre-clinical trials to commercial production”.

The facility consists of 14 reactors, with volumes in the range of 160l to 250l, and was integrated into the R&D centre of Lonza Exclusive Synthesis and the microbial fermentation unit, Lonza Biotec, at the Visp site.

Plant capacity subscripton

Following the investment made in new capacity Lonza was hit by product manufacturing cancellations in mid 2005, which hit its custom manufacturing profits.

The two new production lines at Visp were to be used for the production of parenteral grade therapeutic proteins. The scale of the fermentation vessels would provide sufficient material for preclinical and clinical studies and also eventually be able to scale-up for commercial supply. In 2005 Lonza had spare capacity and third-party manufacturers did not want to take it up.

In July 2003, Lonza Biotec had announced an agreement with Celltech to manufacture a range of PEGylated antibody fragment-based drugs. The two companies also reached an agreement on a prior deal relating to Celltech’s arthritis drug, CDP571.

Celltech reserved a fixed annual manufacturing capacity at Lonza Biotec’s 1,500l and 15,000l fermenter systems for recombinant microbial products in Visp, Switzerland, covering the period 2004 to 2010.

Lonza was to provide technology transfer, scale-up, cGMP manufacturing and quality control testing services for Celltech. Celltech was then sold in 2005 and this agreement was thrown into jeopardy. The buyer, UCB of Belgium then decided that the best option for manufacture of the PEGylated antibody drugs was to use the Lonza facilities.

UCB struck a new deal with Lonza booking manufacturing capacity from 2006 to 2012 with an optional extension and also booked both of the 15,000l trains. The first train came into operation in 2005 and the second one came into operation in the second half of 2006. The facility manufactures CDP571 and CDP870 (Cimzia), a treatment for Crohn’s disease and rheumatoid arthritis.

Downstream facilities

The new facilities at Visp are able to offer a fully-validated cGMP ‘ex-proof’ plant with refolding capabilities. The plant is able to process intracellular soluble products such as those produced in inclusion bodies that require refolding, as well as extracellular-expressed products. Refolding is a process of treating proteins that have been formed intracellularly, but when extracted from the cell they may become insoluble. Refolding is a chemical process where these proteins can be encouraged to rearrange their secondary/tertiary structure and form the required product.

Furthermore, the facility is ‘ex-proof’ and therefore able to process organisms which require a feed of organic solvents for successful culture. The purification train at Lonza Visp offers large-scale separation methodologies based upon ion exchange, hydrophobic interaction chromatography, traditional high-performance liquid chromatography, size exclusion and gel-filtration.

Further downstream, facilities at Visp for use on the new production lines include a membrane purification system, a high-pressure homogenizer operating at 12kbar and a new spray drier suite. The project also includes an expansion of Quality Assurance (QA) and Quality Control (QC) services, as well as the R&D activities in Visp. Installation and the supply of equipment was undertaken by BBS Systems, Aerni Ag and Orbimatic.

Compliance and validation

The plant design complies with the FDA’s Centre for Drug Evaluation and Research (CDER) and Centre for Biologics Evaluation and Research (CBER) requirements, including a complex and carefully considered environmental monitoring system. The new facilities are fully compliant with Biosafety Class 2 regulations.

API manufacturing plant

In June 2007 Lonza announced the construction of a new plant in Switzerland, which subsequently opened in June 2010. The plant has provided Lonza with the capacity to manufacture highly potent active pharmaceutical ingredients (APIs) on a large-scale.

The new facility required an investment of CHF80m (€48m, $64.38m) and is situated on the existing site in Visp, where there are also smaller-scale API manufacturing facilities.

The plant was built to meet growing demand for existing highly potent API products and new API opportunities”. High potency APIs and hazardous chemistry markets are fast emerging as more profitable alternatives since the pharmaceutical sector is suffering from over capacity and pressure from lower cost alternatives from India and China.

The extension of the existing API-capacity in Visp is an important component of the overall Lonza Exclusive Synthesis (LES) strategy.

Expansion

In May 2011, Lonza announced plans to further expand the Visp site to provide additional cytotoxic manufacturing capabilities.

The cytotoxic expansion is planned within the existing GMP laboratory suites to increase the production capacity to commercial-scale. The project is estimated to cost CHF24m and is scheduled to be completed in the second quarter of 2012.

The expansion will offer end-to end solutions for range of technologies and catapult the Visp site into a centre of excellence for high-potency manufacturing.