MilliporeSigma, the US life science business of Merck KGaA, Darmstadt, Germany, expanded its contract, development and manufacturing organisation (CDMO) facility in Verona, near Madison, Wisconsin, to increase the production capacity for highly potent active pharmaceutical ingredient (HPAPI) and antibody-drug conjugate (ADC) linker-payload.

Developed with an estimated investment of $69m (€59m), the new facility was opened in June 2022. The expansion facilitated the production of increasingly potent compounds for potential cancer treatment, creating 50 full-time new jobs.

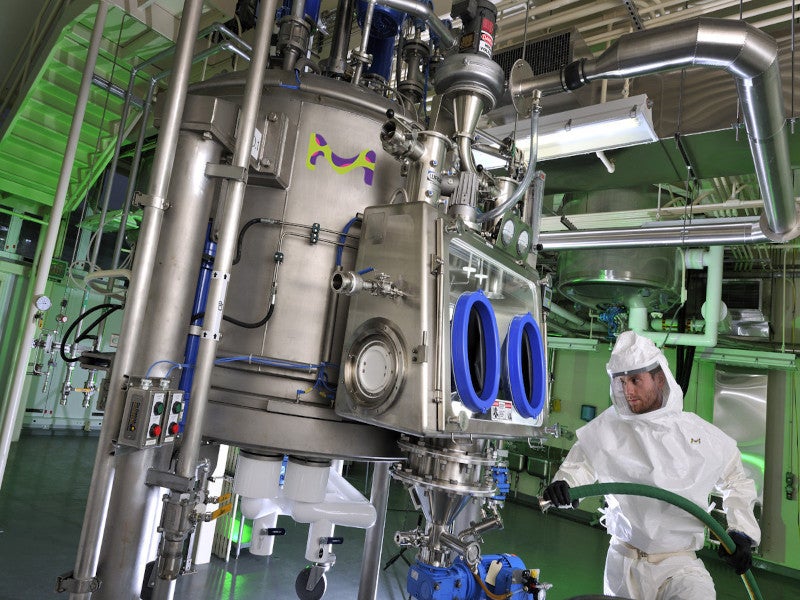

The expansion has doubled the company’s HPAPI production capacity, positioning it as one of the biggest single-digit nanogram occupational exposure limit (OEL) CDMO providers in the world. HPAPIs are assessed using a potency scale, where the most powerful ones have measurements below ten nanograms per cubic metre. Handling HPAPIs with single-digit nanogram potency requires extremely specialised equipment, rigorous procedures and training programmes.

MilliporeSigma’s ADC manufacturing facility expansion

Announced in 2020, MilliporeSigma added a new 6,500m² (70,000ft²) commercial building dedicated to the HPAPI manufacturing facilities near its established Madison campus.

The new structure features one of the largest single-digit nanogram containment production facilities for the manufacturing of HPAPIs. It handles nanogram-single-digit OEL materials, allowing for a continuous flow of ADCs production.

The Madison facility is the first commercial plant in the US dedicated to the development of ADC and handles highly active materials.

The new expansion builds upon the company’s ADC manufacturing capabilities at the existing campus in St Louis, Missouri, which specialises in ADC bio-conjugation, and was the first FDA-approved facility in the US for the manufacture of commercial ADCs.

The company launched ChetoSensar™ technology to address the solubility challenges of ADCs in October 2021. It improves ADC solubility, offering reduced ADC aggregation and improved therapeutic index.

The new ADCore payload intermediate portfolio significantly reduces the time required for ADC development and manufacturing, accelerating the time to market for maytansine, dolostatin and PBD-based ADC payloads by up to a year.

ADC details

ADCs are a group of therapeutics originally designed as a targeted therapy for cancer treatment, developed by linking a cytotoxic anticancer drug payload to a highly specific antibody via a biodegradable linker. Clinical ADCs have expanded to other indications with a variety of payloads and targeting antibodies/ antibody fragments.

The biochemical reaction between the antibody and targeting antigen absorbs the ADC into the cancer cells where the cytotoxic drug is released to destroy the cancer cells.

The production of ADCs is complex and requires a strict containment infrastructure. Its structural exceptionality requires experience in various technologies for small and large molecules, as well as analytical capability.

There are currently 13 different ADCs in the world that hold approval, with the ADC market projected to hit $15bn by 2030.

Details of MilliporeSigma’s ADC manufacturing facility in Madison

MilliporeSigma’s existing manufacturing facility in Madison and Verona handles HPAPIs, APIs, linkers, cytotoxic materials, payloads, and secondary metabolites.

The facility has a wide range of manufacturing spaces and equipment. It not only has the requisite versatility for the multi-step synthesis of complex and HPAPIs but it can support the development and production of complex small molecules from pre-clinical to commercial scale.

Kilo and pilot-scale facilities and equipment are certified for handling Safebridge® Cat IV materials and can support HPAPI manufacturing. Large-scale production facilities can also handle potent APIs (Safebridge® Cat III) qualified.

Some of the safety features of the facility include differential room pressure designed for containment, airlocks, HEPA-filtered single-pass air and contaminants captured with safe-change filters.

The Madison and Verona facilities’ experience in linker and payload technology manufacturing combines with the St Louis-based clinical and commercial ADC facilities to provide comprehensive supply chain solutions.

The solutions include the company’s capabilities for process development and cGMP monoclonal antibody manufacturing for clinical and commercial supplies.

Marketing commentary on MilliporeSigma

MilliporeSigma is a global life science company that delivers vast expertise in both clinical and commercial manufacturing, development and testing. Furthermore, it has more than 35 years of experience in the production and manufacture of small molecules, biologics, and ADC technologies.

The life science business of Merck KGaA, Darmstadt, Germany, which operates as MilliporeSigma in the US and Canada, has more than 28,000 employees and more than 55 total manufacturing and testing sites worldwide, with a portfolio of more than 300,000 products focused on scientific discovery, biomanufacturing and testing services.

BioReliance® Contract Testing Services and the recently formed Millipore® CTDMO Services are part of the Life Science Services business unit, which together with the process solutions business is one of the “Big 3” growth drivers of Merck KGaA, Darmstadt, Germany. The company aims to increase its group sales to approximately €25bn ($27bn) by 2025. Around 80% of the planned sales growth is to come from the “Big 3” businesses.