NextPharma’s Clinical Trial Services (CTS) facility in Gottingen, Germany, launched in December 2008. The facility is an addition to NextPharma’s Gottingen site, which also accommodates a cephalosporins facility and a solid-dosage form manufacturing and packaging facility.

The facility is cGMP compliant and meets European compliance regulations. It is currently being validated by the US Food and Drug Administration (FDA). The facility can support randomisation, double-blinding, emergency letter generation, packaging, kitting and labelling of drugs, and provides cold-chain storage, distribution, drug accountability and destruction.

In February 2011, NextPharma was acquired by an affiliate of Sun European Partners.

CTS Facility

The CTS facility is designed to meet the specific requirements of pharmaceutical and biotechnological companies, universities and contract research organisations. It houses a range of packaging suites to support the primary and secondary packaging for non-clinical, Phase I and II clinical trials. There is an extended cold storage area that operates on temperatures ranging between -28°C and -°20°C.

One packaging suite has been dedicated to the secondary packaging of high-potency drugs. The suite can also carry out primary packaging under inert gas conditions.

The facility also boasts a suite for packaging investigational medicinal products that are sensitive to humidity.

A new ModuC LS IPC encapsulation / over-encapsulation machine was installed at the facility in April 2011. The fully automatic line is designed to fill and over-encapsulate a host of products in solid and liquid form. It is equipped with filling stations for powders, granules, pellets, tablets, capsules and microtablets, and can be operated separately or in combination. The new line allows NextPharma to encapsulate and over-encapsulate up to 20,000 units per hour.

Production

Besides servicing non-clinical Phase I and II trials, the facility provides packaging and distribution services for significant Phase III and Phase IV trials. Pharmaceutical forms packaged in the facility include tablets (film-coated, chewable, effervescent, dispersible), hard gelatine capsules, granules, pellets, ointments, gels, creams, emulsions, suspensions, suppositories and foams in solid and semi-solid categories.

Within the liquid and sterile category, the facility undertakes aseptic packaging of syrups and oral liquids and topical sprays, parenteral liquids, nasal sprays, eye and ear drops.

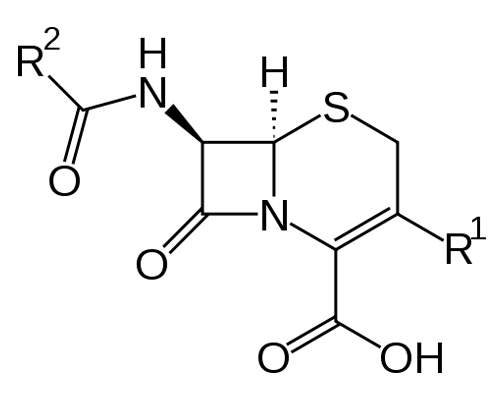

The facility also provides packaging for special product capabilities, including cytotoxics and biologics in freeze-dried and solution-dosage forms, hormones in solid and semi-solid dosage forms and penicillins, cephalosporins and controlled substances in solid dosage forms.

CTS manufacturing at the facility includes blinding of the investigational medicinal products for clinical trials. Development of matching placebo and de-blistering of investigational medicinal products is also undertaken.

The facility also offers analytical services, including method transfer, development and validation, stability testing and storage in compliance with International Conference on Harmonisation requirements. It also offers API and excipients testing for import, EU release and microbiological investigation, in accordance with pharmacopeia.

Process technology

Primary packaging at the facility uses nitrogen cover gas. High-density polyethylene and glass bottles are used for bottle filling packaging. Blister packaging uses polyvinylidene chloride-coated polyvinyl chloride films, alu-alu foils, cyclic olefin copolymer and Aclar films.

For secondary packing, blister cards are used. Special label design and printing is carried out using booklet labels and tear-off labels. Blinding of investigational medicinal products is achieved through over-encapsulation.

NextPharma’s Gottingen Site

NextPharma also operates a production facility that produces cephalosporins in multiple dosage forms. The 1,600m² facility produces film-coated tablets, fills glass and plastic bottles of dry syrup, packages hard gelatine capsules and conducts all kinds of blistering. It has a 900m² GMP production area and a 700m² warehouse, goods arrival and dispatch area.

The solid-dosage form manufacturing and packaging facility at the site occupies 9,000m². It has 4,600m² GMP production space, 950m² of quality laboratories, a 2,600m² warehouse goods arrival and dispatch area, 2,000m² administration area, 600m² CTS department and 750m² space for an R&D building.

A new bottle filling line for tablets was added to the facility in July 2010. The 45m U-shaped line is equipped with a separate primary filling and sealing area and a secondary area for labelling and packaging.

The facility carries out the tableting of film coated, chewable and effervescent tablets, granulation, capsule filling and sachet filling, as well as all varieties of blistering.

Designed to meet the highest GMP and FDA requirements, the line can also fill different types of tablets, capsules and coated tablets into differently sized plastic and glass bottles. It can currently support six bottling formats.

In September 2010, the microbiology facilities at the site were expanded with the addition of three new laboratories. These laboratories have been equipped with advanced air ventilation, laminar flow benches and incubators with improved temperature control. They are EU and FDA compliant and meet the highest GMP requirements.

The laboratories have been designed for the development and validatation of microbiological methods, and for testing the microbial purity and preservative efficiency of non-sterile pharmaceutical products, medical devices and cosmetics. The laboratories will additionally be used to process samples and increase the rate of testing. The microbiology department currently operates at an annual testing capacity of 40,000 samples.