The Annan facility, situated on a 154-acre site in Dumfriesshire, is currently part of Phoenix Chemicals. It has three independent manufacturing and development buildings, all of which have been upgraded to provide new capacity for manufacturing scale, pilot scale and scale-up development for contract manufacturing.

The site was once part of GlaxoSmithKline. Rhodia Pharma Solutions acquired it in 1997, and invested more than £10m in the facility in the ten years up to 2006. Another £1.8m of investment was supplied in this period as a grant from the Scottish Enterprise R&D Plus programme

Shasun Chemicals & Drugs bought the facility from Rhodia in March 2006, but after two years it announced it would close the site and focus it activities at a larger site at Cramlington, near Newcastle. The closure finally came about in March 2009, owing to reduced demand for one of the key products produced there.

Phoenix Chemicals acquired the site in September 2009 for an undisclosed amount. In November the company announced that it had received permission from the Scottish Government to reopen the plant. Phoenix plans to invest £4m in the facility up to 2012, creating more than 50 new jobs.

API manufacturing facilities

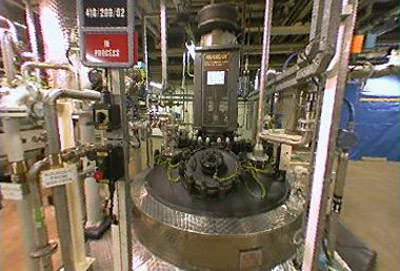

The Annan facility is cGMP (current good manufacturing practice) validated and specialises in the production of bulk active pharmaceutical ingredients (APIs). It also has facilities for development and scale-up operations if required. The site has 31 reactor systems of up to 9,000l in size, giving a total capacity of 30,000gal.

The A3 production building (built in 1990 at a cost of $60m) is dedicated to API manufacture. It’s equipped with a 7,000l crystallisation vessel, a 7m² pressure filter, a 4,000l dryer, a high-vacuum distillation unit, 50,000l of reactor capacity and an isolation suite in a Class 10,000 cleanroom.

The A2 production building has 35,000l of reactor capacity in two glass-lined vessel trains with 6m² and 7m² pressure filters, and 2,500l and 4,000l blender dryers. In addition, there is a 10bar hydrogenator and a Class 10,000 cleanroom.

The A1 production building also has 35,000l of reactor capacity in two vessel trains (both glass and Hastelloy) with three pressure filters (7m², 5m² and 2.4m²) and two 2,500l blender dryers.

Rhodia also introduced hydrolytic kinetic resolution to the Annan facility. The process allows the selective hydrolysis reaction of one enantiomer of a racemic mixture of terminal epoxides (in conjunction with a chiral Co(Salen) catalyst) to produce a chiral diol, which can be easily separated from the unreacted epoxide. This process makes chiral resolution much easier.

Facility upgrades

DawTech was responsible for the upgrade of the A3 building and its Class 10,000 cleanroom, which consists of an offload area with two airlocks, a keg-handling area, an air suit changing area and a dirty changing area. DawTech technology incorporated into the system includes a double HEPA (high efficiency particulate air) filter Trox BOX design, which allows make-up air to be discharged into the building instead of outside, minimising duct work.

Upgrading the other buildings on the site relied upon modern laser scanning techniques as part of the planning process. The laser scanning was carried out by Babcock Rosyth Engineering on behalf of Foster Wheeler, who planned part of the facility upgrade.

Products

Rhodia used the Annan plant to produce WS-23 (N-2,3-trimethyl-2-isopropylbutanamide), a favour and fragrance building block often used in pharmaceutical products as a taste enhancer. It is also used in beverages, cosmetics, chewing gum and shower gel.

The plant has also been used to produce APIs for use in the manufacture of a new drug to treat bone cancers.