Sandoz, a generic pharmaceuticals company based in Switzerland, opened an antibiotic manufacturing facility in Kundl, Austria, in November 2023.

The facility supports increased production capacity of finished dosage form (FDF) penicillin, the most widely used class of antibiotics worldwide, in Europe. It helps to better serve patients with critical antibiotics in more than 100 countries.

The facility, together with a new biosimilar development centre in Holzkirchen, Germany, supports the company’s plans to strengthen sustainable production and supply of crucial medicines in Europe and beyond.

The ground-breaking ceremony for the facility was held in November 2022. The facility became fully operational in March 2024.

AMR certification

In November 2023, Sandoz’s new facility became the inaugural site to undergo the pilot process for the newly introduced global Minimized Risk of Antimicrobial Resistance (AMR) certification. The certification programme, initiated by the business improvement and standards organisation BSI in June 2023, aims to validate responsible antibiotic manufacturing practices within the global supply chain.

Sandoz consequently emerged as the pioneer among all companies worldwide to attain the BSI Kitemark certification, demonstrating compliance with the latest international standards for mitigating the risk of AMR.

Sandoz’s antibiotic manufacturing facility details

Sandoz’s new three-storey building connects to the existing penicillin production facility in Kundl, expanding its footprint by 1,875m² (20,182ft²).

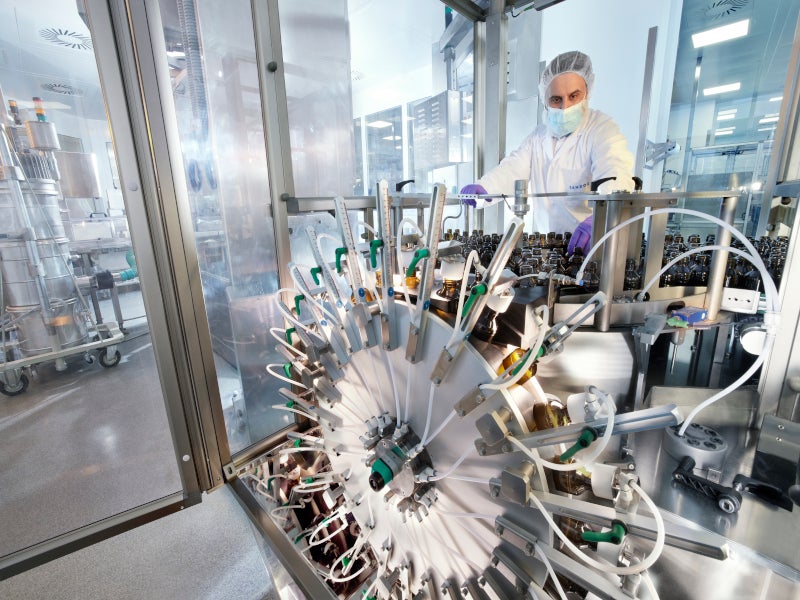

The facility focuses on bulk formulation and fill-finish activities for penicillin, intended for global distribution.

The facility includes automation and state-of-the-art technology for active pharmaceutical ingredient (API) manufacturing and FDFs. The simplified processing enables Sandoz to integrate all production steps into one site, boosting capacity and enhancing supply consistency.

Utilising innovative technologies within its 3,000m² manufacturing area, the facility enables the production of an extra one billion penicillin tablets and a twofold increase in the quantity of powder oral suspensions (POS), primarily utilised in paediatric medications.

The facility and automated production lines enhance production capacity by 20% in comparison to the existing annual capacity of 200 million packages. The expansion in FDFs signifies that Kundl’s production capacity stands at 240 million packages a year, representing more than double the output levels observed in 2021.

The latest manufacturing technology implemented at the site facilitates the production of oral amoxicillin, serving as the API for its primary penicillin product.

Investment details

The project involved an investment of €150m ($160.4m), including a €100m investment from Sandoz and €50m from the Austrian federal government.

The investment enables Sandoz to strengthen its foothold in Kundl, positioning it as the core of Europe’s sole comprehensive antibiotics supply chain, encompassing all stages of production from API to FDFs for numerous prominent antibiotics.

The investment is part of a more than €250m ($248.8m) planned investment into the Sandoz antibiotics network across Europe.

Sandoz’s additional investment in biosimilar capabilities

Sandoz invested approximately €25m in its site in Holzkirchen, Germany, to transform it into a biopharma technical development hub, expanding its biosimilar development capabilities for future growth.

The investment allows the site to become the leading analytical characterisation centre for biosimilars. The facility was inaugurated in November 2023.

Sandoz is investing an additional €50m ($60.7m) for sterile API production at Palafolls, Spain, for new production technology and improved capacity to produce sterile penicillin APIs and sterile API mixtures.

As a component of its network modernisation strategy, Sandoz intends to discontinue the current manufacturing of oral APIs at the Les Franqueses site in Spain, slated for closure in 2024. The transfer of sterile API production from Kundl to the new Palafolls facility is scheduled for 2025.

Additionally, Sandoz is building a new biologics manufacturing plant in Ljubljana, Slovenia. It involves an investment of approximately $90m to grow its global biosimilar portfolio. The proposed facility is expected to be fully operational by late 2026 and is estimated to generate 200 new jobs.