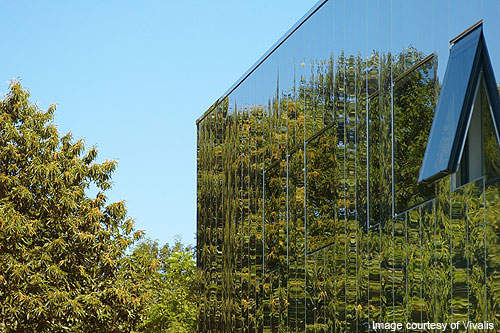

Vivalis opened a new R&D facility in Saint-Herblain, Nantes, France on 28 June 2010. The facility, located adjacent to its existing bio-production facility, has been designed to accommodate all R&D teams at one site. It has been constructed at an investment of approximately €6.5m, which includes €5.5m for the building and approximately €1m for the equipment.

The new facility will allow Vivalis to fast-track its development projects and simultaneously provide its employees with a better working environment. In comparison to the existing cGMP facility, the new facility is designed to consume 25% less energy.

Facility

The new facility is spread over 3,300m² and accommodates state-of-the-art cell biology research and discovery laboratories. It is installed with biological research equipment for virology, molecular biology, process development and activities related to drug screening.

The R&D activities were earlier carried out within Vivalis’ 2500m² cGMP production facility, also located in Saint-Herblain, Nantes, France. Opened in 2005, the facility included a separate unit dedicated for R&D activities. The facility additionally accommodates three separate multi-purpose suites that are equipped with up to 100l bioreactors. The suites conduct manufacturing of biologics in EB66 and CHO cells. The facility also houses a pharmaceutical filling room.

Production

The new facility will derive EB66 cell lines following the cGLP principles. Laboratories dedicated for cell biology research will conduct isolation, culture, and expansion of animal embryonic cells. EB66 cell lines are produced for vaccines as well as proteins. The EB66 cells for vaccines have the ability to replace the embryonated eggs or chicken embryo fibroblats (CEF) for the industrial production of several human and animal vaccine systems.

The discovery laboratories will perform research for anti-viral small molecules using the 3D-screen platform. The 3D-screen technology allows new chemical bodies to be identified in the framework of collaborative research and development partnerships in the field of anti-virals. The laboratories will additionally conduct research and development activities associated with the optimisation of processes for the production of recombinant proteins on the EB66 platform.

Vivalis EBx technology

The facility will derive EB66 cell lines, using the company’s patented EBx technology. Vivalis EBx technology platform allows production of both vaccine and protein under both research and commercial licenses. Besides being cost effective, the technology is simple, fast, more hygienic and a more robust system.

Using the technology, duck embryonic stem cells are used to produce substrate cell lines. The process starts with separation of the avian embryos at the developmental stage. This is followed by suspension of the avian embryonic stem (ES cells), derived by dissociation of avian embryos in a basal culture medium. The medium is supplemented by growth factors and foetal calf serum. The suspension of ES cells obtained is seeded on a layer of feeder cells and further cultured.

Another round of culturing is carried out after all the growth factors are withdrawn. To get a complete withdrawal of feeder cells, the concentration of feeder cells is gradually reduced after which the ES cells are cultured again.

Likewise the ES cells are cultured after the animal serum is gradually reduced.

At the end of this process, the adherent avian EBx cell lines are derived, which may then be further adapted to suspension culture conditions.

The cells produced demonstrate favourable characteristics including genetic stability, diploid karyotype, indefinite cell proliferation capability and strong expression of ES specific markers including telomerase.

Besides allowing the cells to be cultured in serum free media, the technology allows rapid proliferation in bioreactors at high cell densities as suspension cells.

Financing

The facility has been financed by a combination of sources including state and local bodies. Approximately €2.4m has been contributed by DIACT, Region Pays de Loire, Departement of Loire Atlantique and Nantes Métropole. Bank loans amount to €2.5m while the remaining €1.6m has been sourced by Vivalis internally.