A Contract Testing Laboratory always tries to ensure that, wherever possible, it has more than one of any particular piece of equipment to ensure continuity of service. Maintaining a back-up is achievable for smaller instruments that tend to only require a standard electrical connection and a workstation PC. It becomes a more complex matter for larger instruments that require additional services and have sizeable footprints and significant purchase and running costs

The Pharmacopoeia General Chapters allow alternative validated/verified methods to be used in place of the prescribed tests. However, customers of Contract Testing Laboratories are often reluctant to use these. It is therefore necessary for the laboratory to prove the value in the alternative method.

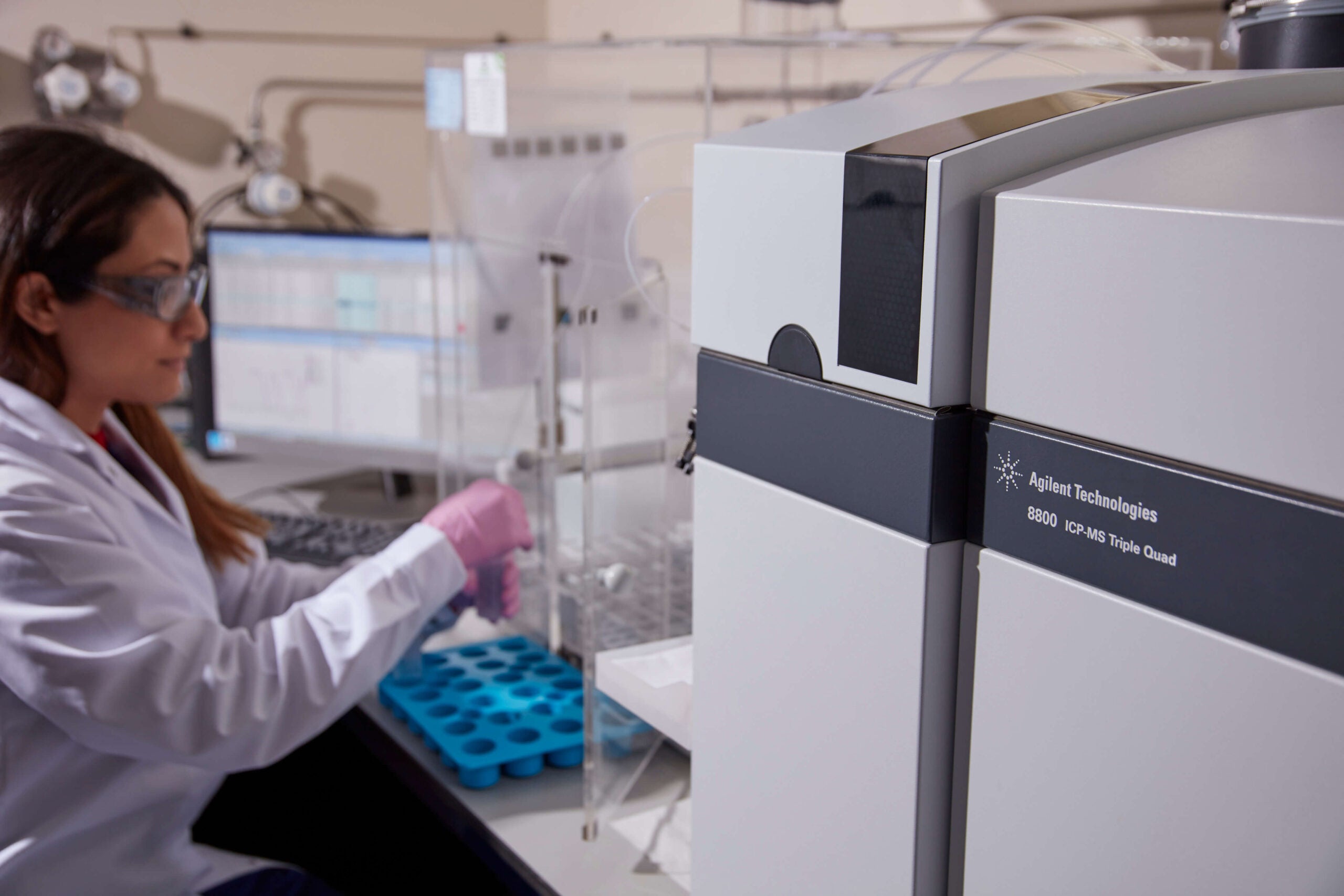

The Heavy Metals colorimetric limit test that was a staple of pharmacopoeia testing has long been recognised as an imperfect and out-of-date procedure. The International Committee of Harmonization (ICH) Q3D process covering the risk assessment of Elemental Impurities has now reached implementation stage via Step 5. This gives guidelines to the industry on how to risk assess Elemental Impurities in pharmaceutical products. Over the past few years the Pharmacopoeia have updated or replaced their General Chapters to remove the wet chemistry Lead equivalent colorimetric test with new testing guidance. Elemental Impurities testing is now routinely carried out using ICP-MS, which enables the required quantitation limits to be reached. To be able to perform ICP-MS analysis, laboratories are required to invest in new instrumentation and the installation of the necessary infrastructure to handle liquid Argon and other gas and electrical resources.

Like many laboratories, Butterworth has equipped itself with back-up instrumentation to ensure an ongoing service is always available. This means methods we may have developed using AAS are now performed using ICP-MS as an alternative. The result is that our AAS is now used far less frequently and almost exclusively when customers require us to follow a monograph to the letter.

At the time of the implementation of ICH Q3D, along with a number of other companies, we began assessing what the future would hold for monographs containing AAS tests. One such example is the Ph.Eur monograph for Magnesium Stearate, which requires Lead, Cadmium and Nickel to be quantified using Graphite Furnace AAS (GFAAS). GFAAS is a powerful technique in cases where large numbers of samples require a single element analysis on an ongoing basis. Butterworth Laboratories has extensive experience of this testing and has found that in the laboratory environment it may be prone to contamination and precision issues. Using ICP-MS as an alternative can enable the laboratory to determine the three elements listed in the Magnesium Stearate monograph simultaneously. In addition, the further 21 elements in ICH Q3D can also be assessed to the same degree of accuracy in a much shorter timescale.

As instruments get older, laboratories now need to consider whether they replace their ageing GFAAS capabilities, and, if so, with what? Can the investment in a new GFAAS instrument be justified if the laboratory already has an alternative instrument capable of producing superior data using a different technique? Investing in a back-up ICP-MS may be the preferred option instead, given the investment in the facilities already made.

The question remains: when will the Pharmacopeia update the monographs that use GFAAS with the superior technique of ICP-MS? Nearly 10 years on from the introduction of ICH Q3D and the recognition of ICP-MS as a pharmaceutical technique, we appear to be no nearer finding out. But perhaps the need to update older techniques and meet Data Integrity requirements may finally move this question up the agenda.