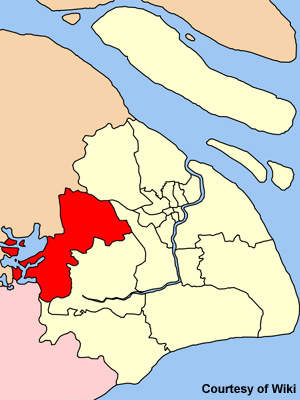

China-Biotics is one of China’s largest suppliers of probiotics. In 2009 it opened a bulk additive production facility in Shanghai Qingpu Industrial Park, Qingpu County, Shanghai. The facility began commercial production on 1 March 2010. The facility was constructed at an estimated cost of $18m, funded partially from the company’s existing and operating cash flows.

The facility obtained Good Manufacturing Practice approval from the Shanghai Food and Drug Administration in April 2010.

Facility

The state-of-the-art facility consists of three buildings situated on a 54-acre site. It has approximately 20,000ft² of production space and a world-class fermentation workshop. The workshop’s control system is custom-designed to use China-Biotics’ proprietary fermentation technology.

The facility also houses a multi-purpose office that will serve as an education centre to demonstrate the company’s products and educate visitors on the manufacturing process of probiotics.

Construction

Construction began on 30 November 2007. By the end of August 2008, approximately 130,000ft² of manufacturing space across two-levels was complete. Phase I included the construction of three buildings and the installation of equipment. Testing and trial production took place between July and October 2009. Phase II will oversee further expansions to scale-up production capacity to 300t a year.

Probiotic health benefits

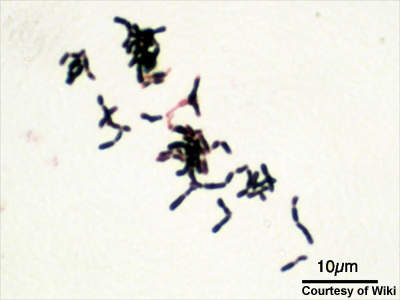

Probiotic bacteria are commonly used as a food supplement and additive, especially in dairy products such as yoghurt. It purportedly benefits gastrointestinal health and digestion and improves the immune system. Probiotics reduce the intolerance of lactose and fight allergies. The demand for probiotics for use in the bulk additive market is rapidly increasing and is currently being met by imports.

Production

The facility will produce probiotic-based products including synbiotic capsules, gegen capsules, probiotics tremella polysaccharide capsules and chewable tablets.

Synbiotic capsules, made primarily of lactobacillus thermophilus, infant bifidobacterium, bifidobacterium bifidum and oligofructose, boost the immune and gastrointestinal system of adolescents.

Gegen capsules include lactobacillus acidophilus and bifidobacterium bifidum (LA-BB). Probiotic tremella polysaccharide capsules, composed of LA-BB and tremella polysaccharide, boost the immune system and gastrointestinal health of elderly people. Chewable probiotic tablets, made of lactobacillus acidophilus, infant bifidobacterium and taurine, reduce the build up of enteric pathogenic bacteria and enhance energy levels.

To supply probiotics as bulk additives for yoghurt and other beverage products, China-Biotics entered into a contract with four food manufacturers on 14 January 2009. Under the one-year contract, China-Biotics will supply probiotics to Shanghai Yuejia Food, Shandong Huwa Dairy Industry, Qinghai Xuefeng Yak Dairy Industry and Shaanxi Yulin Dairy Product.

The number of bulk customers had reached 39 by the end of June 2010. Four are producers of animal feed, while the remainder are dairy enterprises.

Capacity

The facility is designed to produce 150t of probiotics per year. In the second quarter of 2010, the facility produced more than 15t of probiotic products. By the end of June 2010, the production capacity at the facility was ramped up to 60t per year, and this is expected to rise again to 75t per year by the end of December 2010.

The annual production capacity of China-Biotics is currently 12t, met primarily by its facility in Pudong in Shanghai.

The Pudong facility can produce up to 3.5 million capsules every month. The patented production process of the facility is ISO 9001, ISO 14001, OHSAS 18001 and HACCP-certified. All certifications have been verified by TÜV Rheinland/Berlin-Brandenburg Group of Companies.