The University of California, Santa Cruz (UC Santa Cruz) Biomolecular Engineering team has developed new methods for the production of HIV vaccines in the US.

Led by professor Phil Berman, the team aimed to address the existing technical difficulty with producing vaccines depending on the envelope proteins of the virus.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

Such technical problems with manufacturing are believed to have led to a delay in evaluation of majority of HIV vaccines in clinical trials.

Berman said: “Dozens of interesting vaccine candidates have been described, but most have not been tested in humans because it has not previously been possible to manufacture them affordably and in a timely fashion.

“The technology we developed should break the logjam in HIV vaccine development, because it tremendously shortens the time, improves the yield, and lowers the cost.”

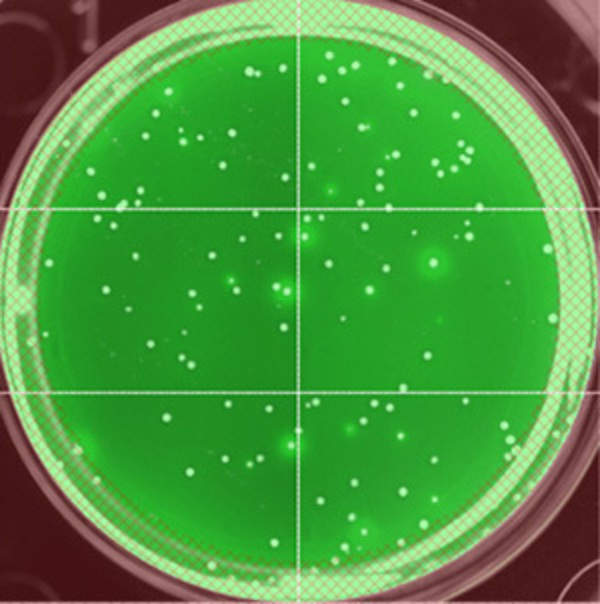

The team used robotics to reduce the time taken to produce stable cell lines and make proteins for a vaccine, along with increasing the amount of proteins produced by the cell lines.

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalDataAccording to the researchers, the improved yield enables decrease in size of the bioreactor used to produce vaccine for large clinical trials, leading to savings in the equipment and material costs.

Berman added: “The carbohydrates attached to the protein are really important, something no one realised until recently. The conventional way of making these envelope protein vaccines incorporated the wrong kind of carbohydrates.

“We now know that destroyed many of the important antigenic sites recognised by protective antibodies.”

Berman’s lab created a robotic method to separate high-producing cell lines making HIV envelope proteins, resulting in shortening of the time required for manufacturing stable cell lines from 18-24 months to two or three months.

They used new gene editing technology called CRISPR / Cas9 to develop a new cell line named MGAT CHO that produced proteins similar to those found on a HIV envelope.