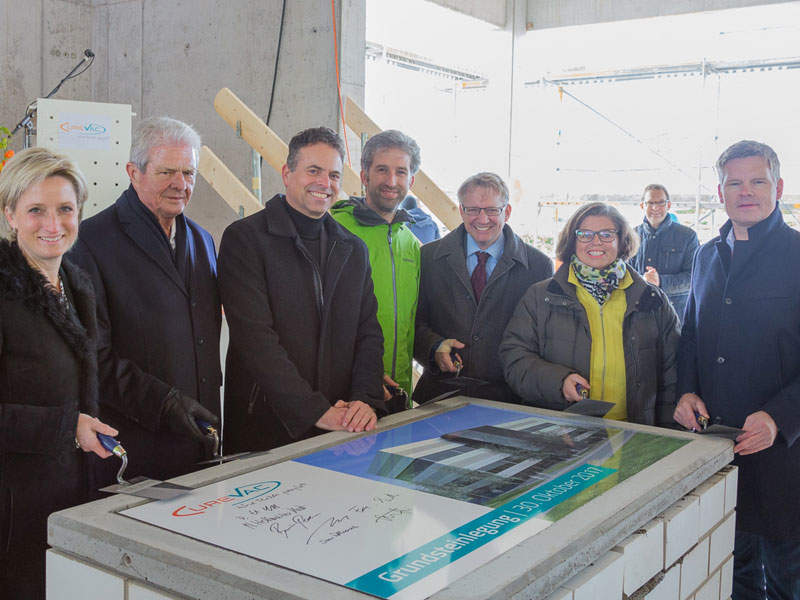

German pharmaceutical company CureVac is developing a good manufacturing practice (GMP) compliant ribonucleic acid (RNA) production facility at its headquarters in Tubingen, Germany.

Planned to manufacture 30 million doses of RNA-based therapeutics a year, production at the facility is scheduled to begin in 2018, with commissioning expected to be completed in 2019. Its construction began in October 2017.

The facility will expand CureVac’s manufacturing capabilities and meet growing demands for clinical trials and product commercialisation.

Details of the CureVac GMP IV facility

With an 8,800m² floor space, the facility will be used to produce a wide range of RNA-based products, including RNActive®, RNArt®, RNAntibody® and RNAdjuvant®. These products are approved for treating cancer and infectious diseases among other indications. The plant will also have the potential for future expansions.

Production process at the CureVac GMP plant

RNA active ingredients produced at the plant can be used to treat various diseases and infections. A patent-protected production process is standardised for all RNA constructs.

The plant can manufacture multiple products, smoothly switching from one production method to another in a matter of hours. The platform also removes the need to develop validation concepts for new products.

Production processes can be scaled according to different quantities, from small and customised batches to commercial-scale output.

RNA and vaccine production at the plant

The GMP-compliant plant will be used to produce vaccines in the event of a pandemic. Vaccines can be made quickly using a biotechnological in-vitro process that uses naturally occurring components as source materials.

The plant will also adhere to the PureMessenger® method of production, which ensures pure and consistently high RNA quality. It will be equipped to manufacture new RNA sequences in GMP quality within a few weeks. The production process also significantly minimises the cost per dose.

CureVac’s proprietary technology uses mRNA as a data carrier to instruct the human body to produce proteins capable of fighting various diseases. The company’s technologies are used to develop cancer drugs, vaccines and molecular therapies.

Marketing commentary on CureVac

Established in 2000, CureVac was originally a spin-off from the University of Tϋbingen.

It is one of the first companies to have initiated clinical trials on mRNA-based drugs, and has more than 17 years of experience in producing RNA molecules for various indications.

CureVac has been operating GMP-compliant RNA production plants, named GMP I and GMP II, since 2006. It also recently completed GMP III, a third in-house suite for manufacturing RNA products.