In July 2008, Gedeon Richter, one of Hungary’s largest pharmaceutical companies, started building a facility for the development and manufacture of biopharmaceutical products in Debrecen. The facility is the first of its kind in Central and Eastern Europe.

The manufacturing facility is part of Gedeon Richter’s long-term strategy to develop its business and expand into new European and international markets.

The construction project required a Ft25bn ($110m) investment and the plant became operational in April 2012.

During the initial operating period, the plant produced samples for clinical trials. drugs for the commercial market are planned to be manufactured from 2016.

The facility created more than 200 jobs. The company is investing Ft15bn ($54.5m) in the biopharmaceutical plant to expand its production capacity for biosimilar products. The expansion is expected to create a further 125 jobs.

History of the Gedeon Richter manufacturing facility

In 2007, Gedeon Richter decided to enter the field of biotechnology and biopharmaceuticals by establishing biotechnological R&D and manufacturing facilities. In August 2007, Gedeon Richter and German pharmaceutical company Helm AG formed a joint venture company, with 70% and 30% ownership respectively, to develop a biotechnology business using their combined knowledge and finance.

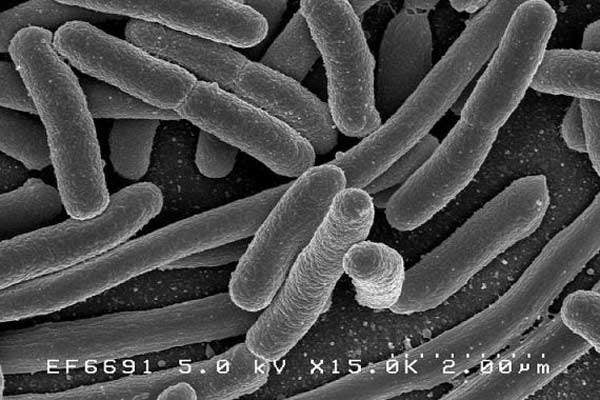

Part of the joint venture involved taking over Strathmann Biotec for a €22.9m ($27.2m) consideration. The new entity, Richter-Helm Biologics, included a state-of-the-art biotechnological plant for the bacterial type of biotechnology, laboratory R&D and pilot plant capacity.

This entity has 81 employees across three German sites and has enhanced Gedeon’s new business. Gedeon had established a small-scale laboratory in November 2005 in Hungary, to be used for the large-scale fermentation of recombinant proteins for human use.

Details of the Gedeon Richter facility in Debrecen

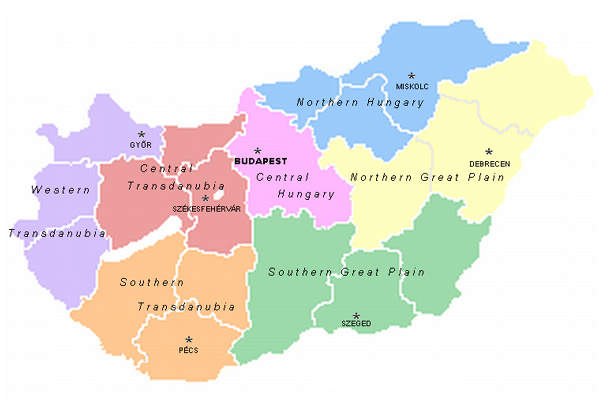

The site for the biotechnology facility was affected by a number of factors, including transport access to a motorway, the provision of industrial-scale services and surrounding infrastructure capacity. Gedeon Richter’s management decided to build the facility at the Debrecen industrial park.

Gedeon Richter applied for a preliminary environmental permit in February 2008 and subsequently received the resolution of the regional Inspectorate for Environmental Protection, asking for a detailed environmental impact assessment and documentation relating to an integrated permit for the use of the environment.

These documents were submitted in May 2008. A public hearing was held on 25 July 2008 to answer any questions.

Gedeon also submitted its application for a business licence to the Hungarian National Institute of Pharmacy (OGYI) in May 2008.

The Hungarian Government provided financial incentives to the project because of its creating jobs and its contribution to the economy.

Construction of the Hungarian plant

In September 2008, US-based company Jacobs Engineering Group announced that it had received a contract from Gedeon Richter to provide engineering, procurement and construction management services and validation assistance for the Debrecen facility.

The plant has a flexible manufacturing unit that can produce therapeutic proteins using insect and mammalian cells and recombinant technology. It can also be used for other technologies with minimal modification.