Novo Nordisk has had research and production facilities in China since 1994 when the company set up Novo Nordisk (Tianjin) Biotechnology Co Ltd, which was later renamed as Novo Nordisk (China) Pharmaceuticals Co Ltd. In 1996, Novo Nordisk’s first modern insulin manufacturing plant in Tianjin started production.

In May 2002, the facility based in the Tianjin Economic-Technological Development Area underwent expansion with the construction of a new manufacturing plant. The 40,000m² plant, which cost ¥30m, passed GMP authorisation in June 2003 and started production in August of the same year, confirming Tianjin as the company’s major manufacturing site in China. Novo Nordisk has since become the leader in diabetes medication in China with a complete organisation system from R&D, manufacturing and packaging to sales and distribution.

LATEST EXPANSION

In 2004 Novo Nordisk made a decision to expand the production facilities at Tianjin again by building a new assembling and production facility there. The plant, which has been promoted as part of the company’s new expansion programme in China, was commissioned in the third quarter of 2006 and has provided employment for over 100 new personnel.

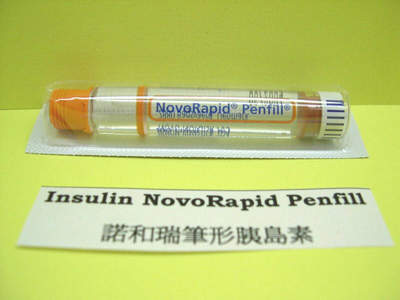

The new plant will meet the growing demand for FlexPen, NovoPen and Penfill products and will cater to both domestic and export markets in Asia. The new 40,000m² facility required an investment of US$128m (DK800m). Novo Nordisk has also expanded its packaging facilities for Penfill insulin cartridges and FlexPen prefilled insulin pens.

As is usually the case with Novo Nordisk plant construction, the work was carried out in a very small timescale and was achieved using modular engineering concepts. Novo Nordisk Engineering (NNE) was commissioned to construct the plant; this was carried out by plant modules being constructed simultaneously by several third party contractors with the modules then being shipped in for final assembly. The plant may go through further phases of expansion as the market develops and the need

arises.

Kåre Schultz, chief operating officer of Novo Nordisk, commented at the inauguration of the new plant in March 2006: “Our expansion in China reflects the internationalisation of our production base and our commitment to the Chinese market. The new plant is yet another example of the increasingly important role China is playing in Novo Nordisk’s global operations, and we will continue to build the Tianjin plant into a world-class insulin production base.”

MANUFACTURING

To aid in the coordination of manufacturing with the distribution of products Novo Nordisk has introduced lean manufacturing at the new Tianjin facility. The company contracted to carry this out was ICE (Intelligent Creative Engineering). With the help of ICE Lean, Novo Nordisk has minimised inventory, increased delivery accuracy and has levelled the resource load in their manufacturing processes.

PRODUCTS AT THE NEW PLANT

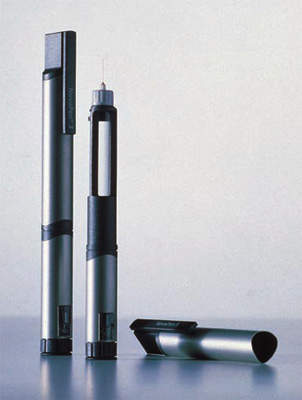

The new plant will assemble the NovoPen 3 insulin pen alongside the expansion of packaging facilities for Penfill insulin cartridges and Flexpen prefilled insulin pens. Flexpen is the latest insulin pen manufactured by Nordisk and will be used to administer the hormone to correct requirements. NovoPen 3 is the most popular and widely used insulin pen in the world with a customer base of about two million diabetics using it on a daily basis.

NovoPen 4 is the new improved version, released at the end of 2006. The new Novopen 4 contains the most successful and innovative features of NovoPen 3 with more user-friendly features and will also be manufactured at Tianjin. The existing NovoPen 3 production plant in Denmark was phased out when the Tianjin plant achieved full production in mid-2006. The Danish plant has been re-equipped, and employees have been transferred to the production of the new NovoPen 4 system.

INSULIN PEN

The Insulin Pen is an insulin delivery system that resembles a pen and uses needles and an insulin cartridge instead of vials and syringes. The pens may be fully disposable or may take an insulin cartridge. The needles for these devices are, however, always disposable and specially made for the insulin pen system, being shorter and thinner than the normal needles. To administer insulin, the cartridge is loaded and screwed on the pen needle. The desired dose is ‘dialled’ on the pen and the needle is injected before the button is finally pressed to deliver the insulin.

EDUCATION ABOUT DIABETES

Since diabetes is fast becoming a major health issue across China as well as other areas of the world, Novo Nordisk also supports various education and prevention programmes. In 2002, Novo Nordisk and the Chinese Ministry of Health launched a project that brings extensive diabetes education throughout China and addresses critical problems caused by the disease. Currently, it is estimated that more than 30 million people in China have diabetes, and that number is increasing rapidly. The education program is helping to make people aware of the risk of developing diabetes.