Sanofi Pasteur, the vaccines business of Sanofi-Aventis, is one of the largest seasonal influenza vaccine producers in the world.

With the increased risk of H5N1 bird flu being passed by human to human and also the increase in inoculations in Western countries of ‘at risk’ areas of the population against seasonal influenza the company has been increasing its production capabilities.

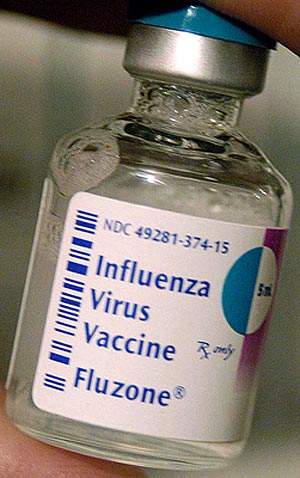

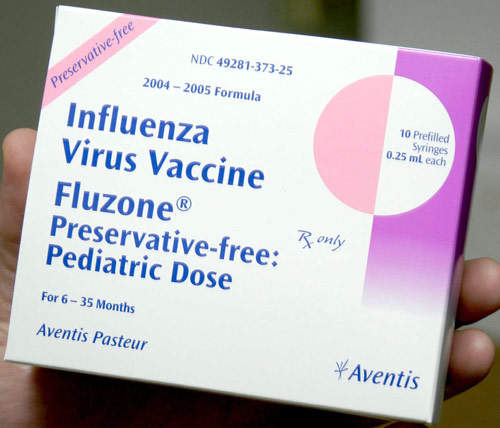

In 2005, Sanofi Pasteur initiated a $150m investment in the US at Swiftwater in Pennsylvania for a new influenza vaccine manufacturing facility, which is anticipated to double its US production capacity to over 100 million doses of influenza vaccine (Fluzone) per year (170 million doses in 2006 out of a total global production of 350 million doses).

The new production capacities were originally planned to come online for the 2008–2009 influenza season. However, the production could not be started till the FDA approval and licensing for the plant was obtained in May 2009. The company therefore planned to produce the vaccine for the 2009–2010 influenza season.

The Swiftwater plant will bring more than 100 new jobs, but will not speed up vaccine production which can take three to four months; it will just make larger batches at once.

A €160m investment, the largest capital investment to date for Sanofi Pasteur in France, has also been approved for a formulation and filling facility in Sanofi Pasteur’s Val de Reuil facility.

The new state-of-the-art facility will boost Sanofi Pasteur filling capabilities, thus significantly reducing time to market for the vaccine.

Construction completed

The construction of the new Swiftwater vaccine facility was completed in July 2007 and following FDA (Food and Drug Administration) validation and licensing approval obtained in May 2009, production of the vaccine has been underway for the 2009–2010 flu season.

The new 140,000ft² (13,000m²) facility will further enable Sanofi Pasteur to support public health and protect individuals against both seasonal and pandemic influenza. Sanofi Pasteur is the only company manufacturing inactivated influenza vaccine in the US.

Sanofi Pasteur chairman and CEO David Williams said: “As the world’s largest supplier of influenza vaccines, Sanofi Pasteur is committed to addressing current and future public health needs by investing in a robust research and development programme and an ambitious production plan for pandemic preparedness.

“The completion of this new facility, incorporating the latest technology in vaccine production, illustrates the company’s priority to produce the largest number of doses of vaccine in the shortest time frame to face the threat of seasonal and pandemic influenza.”

A further boost

The completion of construction of the new plant came after an announcement in June 2007 by the US Health and Human Services Secretary Mike Leavitt, which awarded Sanofi Pasteur a $77.4m contract to retrofit its existing Swiftwater influenza vaccine manufacturing facility (H5N1 readiness). Sanofi Pasteur will contribute approximately $25m toward the retrofit project.

Combining the capacities of new facility with the retrofitted facility should enable Sanofi Pasteur to triple its influenza vaccine capacity in the US. This will make the company the largest supplier of influenza vaccine in the US and the world.

Sanofi Pasteur has also led the way with the first US licensed avian influenza vaccine for humans and has successfully achieved manufacturing scale-up of this first-generation vaccine using proven, licensed and existing technology.

In April 2007 the FDA announced the first approval in the US of a vaccine for humans against the H5N1 influenza virus (avian or bird flu is a severe form of the disease and can cause multiple organ failure).

Andrew C von Eschenbach, Commissioner of Food and Drugs, said: “The threat of an influenza pandemic is, at present, one of the most significant public health issues our nation and world faces.

The approval of this vaccine is an important step forward in our protection against a pandemic.”

Two influenza subtypes, H5 and H7, have caused highly pathogenic avian influenza.

While most vaccine development has focused on H5N1 strains, avian H7-containing viruses remain a significant pandemic threat and have caused infections in humans in Europe over the last three years.

Contractors

Calori and Vanden Eynden were design consultants for the Sanofi Pasteur Swiftwater campus. Borton-Lawson Architecture and Engineering were also involved in the Swiftwater expansion particularly for the waste water treatment facilities. Vanderweil Engineers were selected to develop a concept design for the new vaccine research and development facility.

The facility, totalling approximately 140,000ft², provides space to support new vaccine development and production of clinical products. It consolidates and integrates all development and administrative functions into one building.

The current programme includes cGMP production and support space, GLP laboratories and support space, BSL-3 lab for tissue culture, office/administrative space for Clinical Development, Regulatory Affairs and related support functions. Sanofi Pasteur retained Global Project Services to manage and provide process engineering for the conceptual design and basic engineering of the facility.

Sanofi Pasteur also wanted to install over 20,000ft² of tile and stone in its main lobby, lobby staircase, cafeteria and other highly visible areas of its new administrative building, and the job was awarded to Fromkin Brothers painting and flooring contractors.

Influenza preparedness

Influenza is a highly infectious virus that spreads easily from person to person, primarily when an infected individual coughs or sneezes. According to the World Health Organization (WHO), 5–15% of the population is affected with upper respiratory tract infections in annual influenza epidemics.

Hospitalisation and deaths occur mainly in high-risk groups (elderly, people with chronic conditions/illness). Although difficult to assess, these annual epidemics are thought to result in between three and five million cases of severe illness and between 300,000 and 500,000 deaths every year around the world.

Most deaths currently associated with influenza in industrialised countries occur among the elderly over 65 years of age. It is the ‘at risk’ groups that are targeted for annual immunisation. According to WHO, the next pandemic is likely to result in 1 to 2.3 million hospitalisations and 280,000 to 650,000 deaths in the industrialised nations alone.

Its impact is expected to be even more devastating in developing countries. In an attempt to minimise the impact of a pandemic, many countries are developing national and trans-national plans against an eventual influenza pandemic situation.

Lucrative contracts for vaccines

As part of the ongoing bird flu pandemic preparation Sanofi Pasteur has received several contracts to support efforts in both the US and Europe. A $100m contract awarded by the US department of Health and Human Services (HHS) calls for Sanofi Pasteur to manufacture the vaccine in bulk concentrate form at its US headquarters in Swiftwater, PA from early September through to late October.

The agreement provides for additional fees to be paid to Sanofi Pasteur for storage of the vaccine as well as for formulation and filling of the vaccine upon government request. The contract with HHS is Sanofi Pasteur’s fifth pandemic-related agreement with the US government.

The Swiftwater plant was under warning from the FDA in 2006 due to some monovalent concentrate problems in the manufacturing process. The company also has ongoing supply contracts for bird flu vaccines with France, Australia and the UK.

The H7N1 vaccine (another virulent strain) was produced at Sanofi Pasteur’s Marcy l’Etoile facility in France using PER.C6 cell-based technology from its partner CRUCELL N.V., allowing an alternative production process expected to offer advantages over traditional manufacturing methods. The H7N1 vaccine strain was developed from an avian influenza virus by the UK’s National Institute for Biological Standards and Control (NIBSC) and the University of Reading, UK.