Seqirus, an influenza vaccine maker, is building a new cell-based influenza vaccine manufacturing facility in Melbourne, Australia.

The facility will be a significant addition to the company’s global manufacturing and supply chain for the influenza vaccine, including the facilities in Holly Springs, North Carolina, US, Liverpool, UK, and Parkville, Australia.

The new plant will be utilised to manufacture influenza vaccines for both pandemics and seasonal vaccination programmes, using advanced cell-based technology. It will produce products for the domestic market and export, help Victoria’s 1,000+ STEM workers, and have an estimated supply chain of more than $300m a year.

The development of the facility will cost approximately A$800m ($581.4m). Construction should begin in February 2021, while operations could commence by mid-2026.

It will create approximately 520 jobs during the construction phase and will employ several hundred people upon completion.

The Victorian Government will support the project to expand the globally active community of medical research and biotechnology in the state.

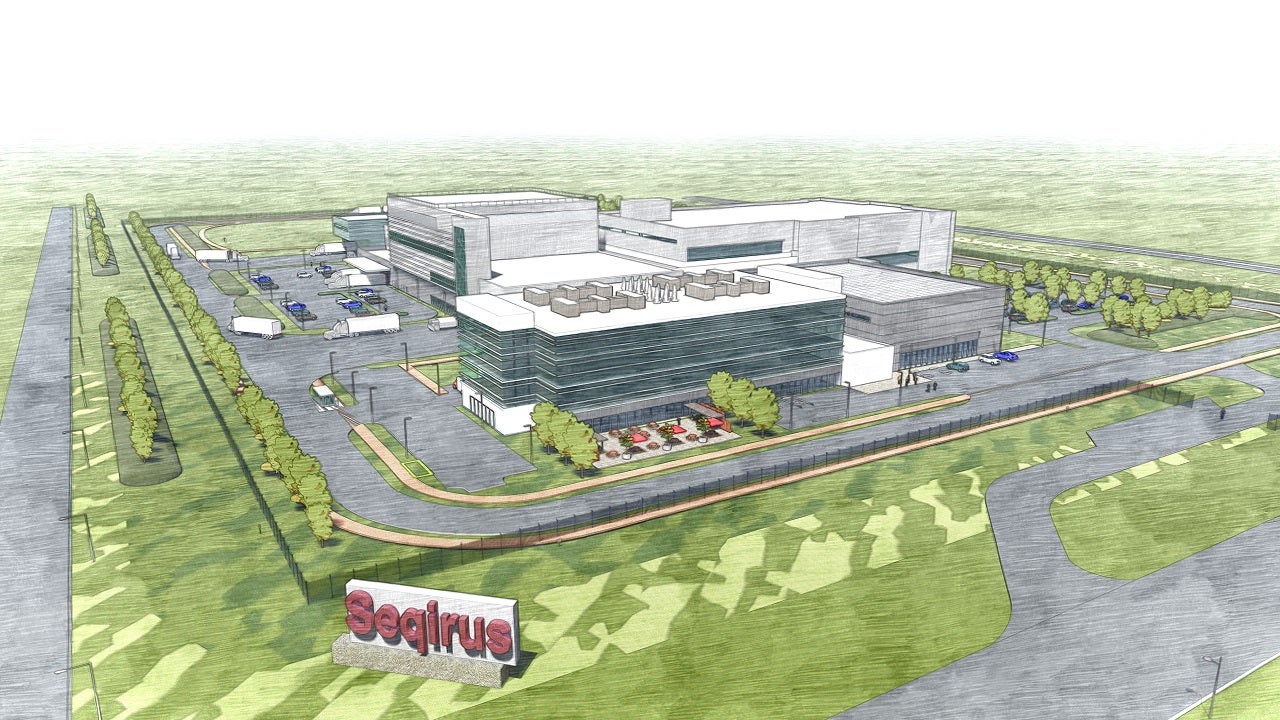

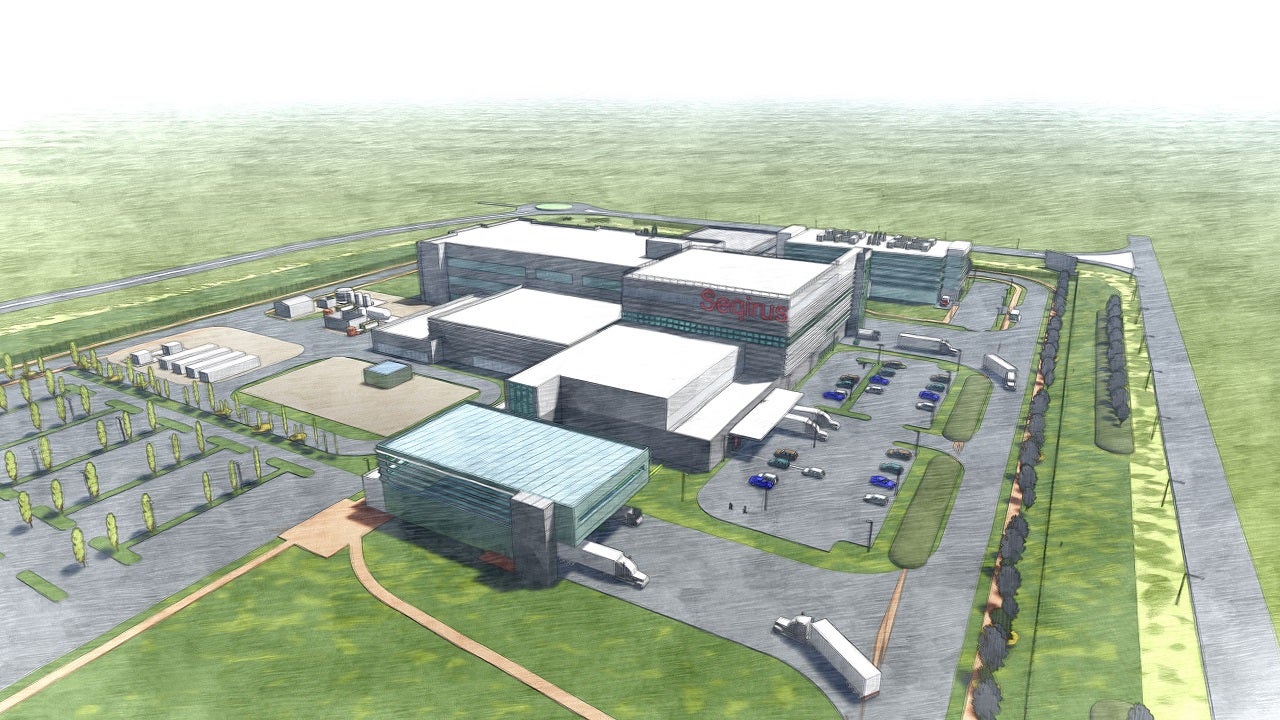

Seqirus’ vaccine manufacturing facility location

The influenza vaccine manufacturing facility will be in Tullamarine in the Melbourne Airport Business Park in Victoria, Australia.

It will utilise the airport’s transportation facility to supply vaccines round-the-clock.

Vaccines produced at Seqirus’ new manufacturing facility

The purpose-built, state-of-the-art facility will be in place to develop MF59®, a proprietary supplement of Seqirus added to certain vaccines to boost immune response and to reduce the amount of required antigen in each vaccine, facilitating rapid and increased manufacturing of doses.

The products specifically essential to Australia’s public health needs, including antivenoms for Australian snakes, spiders, and aquatic species and the world’s only human vaccine for Q-fever, will also be developed in the facility.

Seqirus signed an agreement with the Australian Government to ensure the on-shore manufacturing and delivery of influenza pandemic vaccines, anti-venom and Q-fever vaccines for more than ten years. The supply contract will last until 2036.

Influenza vaccine technologies

Seqirus’ research and development (R&D) produces improved influenza vaccines based on proprietary cell culture and adjuvant technology.

The cell-based technology platform provides a number of advantages over the traditional egg-based manufacturing, including improved scalability, high efficiency, and rapid production of vaccines.

The company introduced the influenza vaccine modernisation with the development of FLUCELVAX® QUADRIVALENT, a four-strain formulation where the vaccine components are grown in state-of-the-art cell-culture bioreactors at its Holly Springs facility. The strategy has several potential benefits, including better manufacturing efficiency and better matching of circulating virus infecting individuals with the virus strains used in the vaccine.

Marketing commentary on Seqirus

Established in 2015, Seqirus is an influenza vaccine company with state-of-the-art production facilities and R&D hubs in the US, UK and Australia. The company boasts of an internationally integrated supply chain and marketing footprint in more than 20 countries.

In September 2020, the company partnered with the Australian Government to supply 51 million doses of V451, the Covid-19 vaccine candidate of University of Queensland, and approximately 30 million doses of AZD1222, AstraZeneca’s COVID-19 vaccine candidate, upon successful clinical trials from 2021.