Across the pharmaceutical sector, governments in major markets are placing increasing pressure on the industry for full visibility and traceability across the supply chain. Strict regulations require that every batch of product, all movements (such as transfers between facilities or during distribution), and every temperature reading (essential to maintain product efficacy and safety, especially for sensitive drugs like vaccines and biotech products) are meticulously documented – and regulatory frameworks are getting more complex in parallel to 21st century scientific discovery and innovation.

Outside the manufacturing facility, the distribution chain must include systems that can protect the quality of medicine ultimately administered to patients, meet all compliance demands and balance that with speed to market all while keeping a lid on costs in an expensive operating environment.

It’s fair to say that pharmaceutical distributors have their work cut out for them in 2026 – and Ocado, the UK business that has blazed a trail in grocery ecommerce logistics since the early 2000s, believes it has the expertise and technological leadership to support the industry’s ability to reinvent its supply chain at this critical time.

The imperative of rewiring pharmaceutical logistics

The Ocado Smart Platform (OSP), a configurable end-to-end ecommerce, fulfilment and logistics solution, has become the backbone of online grocery for more than a dozen global supermarkets, transforming a sector notorious for low margins and delicate dynamics.

Now the firm has brought its pioneering automation software and hardware to support the pharmaceutical sector as it strives to reinvent itself and create value against a volatile macro and micro-operating environment.

Ocado’s first deal for its hi-tech automation software and robotics outside grocery was inked with Canada’s biggest pharmaceutical distributor McKesson Canada, a milestone for the firm and a sandbox moment for the sector worldwide, which will be watching progress closely once the Ocado Storage and Retrieval System (OSRS) goes live at McKesson Canada’s Montreal distribution site.

In this exclusive Q&A for Pharmaceutical Technology, Andy Ingram-Tedd, VP of Advanced Technology at Ocado Intelligent Automation, discusses the imperative of reimagining pharma logistics and his vision for Ocado’s game-changing automation technology and grid design to become the gold standard for safe, scalable, data-driven medicine supply chains.

Q: Andy, Ocado is a household name in online grocery, but you’re now deploying your automation in the pharmaceutical sector. What gives Ocado the edge here?

Andy Ingram-Tedd: Our experience means we have technology that is proven in the most sophisticated and profitable fulfilment centres in the world, developed to meet the demands of a sector with incredibly tight margins, vast product ranges, and every imaginable compliance hurdle. In pharma, the need for accuracy and real-time visibility is just as great, if not greater, than in grocery.

“We’ve helped McKesson Canada consolidate seven separate zones into one unified platform. This is going to empower McKesson to more than double its productivity, which honestly is phenomenal” – Andy Ingram-Tedd, VP, Advanced Technology, Ocado Intelligent Automation

Could you walk us through how Ocado’s Storage and Retrieval System (OSRS) works and what makes it unique?

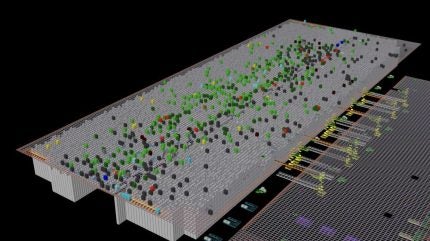

Absolutely. Our proprietary Ocado Storage and Retrieval System – OSRS – is a cubic-based design. We’ve got storage containers stacked on top of each other inside a storage grid, and on top of this, we can run anything from a few robots to a fleet of thousands at once. They glide over the grid like rooks on a chess board, each only occupying a single grid cell, so you can run a lot of them at super high speeds. This set-up allows for much higher throughput.

Each bot is hollow inside, with what we call a ‘grabber.’ When a bot comes over a particular section of grid, the grabber lowers, picks up the top container (or tote) in the stack, and stores it inside the bot’s belly before moving it to wherever it’s needed, be it a station for picking, inventory control, or a machine to outload completed orders ready for dispatch. Crucially, any bot can access any grid cell location.

The system’s modular too. Depending on the client’s requirements or the nature of what’s being picked, you can have human workers at stations when it’s needed – say, for especially delicate products – or you can let robots handle it end-to-end. And, importantly, we operate our own sites, so we know first-hand what happens when things go wrong. Everything we’ve learned over the past 25 years has fed directly into making this a truly resilient solution.

Let’s talk about the software powering this automation. What role does software play in enabling all these capabilities?

Software is absolutely at the heart of what we do, it’s what ties everything together. Before anything is built, we use simulation to create a highly accurate digital model of a proposed warehouse. Using real order data, layouts and operating rules, we can test different design options, explore “what-if” scenarios and predict how the site is likely to perform. The clever bit is that the exact same software driving the simulation is what ends up running the live system, so when we move from design to reality, we know precisely what to expect. AI is a key part of this. We use it for things like route optimisation, deciding which bots move which containers to which stations, and in what order, to maximise efficiency. Advanced computer vision powers our robotic systems, and predictive modelling is essential for everything from stock forecasting to compliance.

What’s more, the software supports regulatory compliance and smarter inventory management. For instance, we can run first expired, first out (FIFO) to reduce waste and improve patient safety by ensuring drugs close to expiry are dispatched first. But it’s flexible too. Hospitals might need last in, first out for certain SKUs. Take something like epi-pens, which must be ready for emergencies and need the longest possible shelf life because they live in the portable storage cabinets in hospitals that only get replenished each season. Typical pharmacies, by contrast, can have anything approaching expiry sent out first. Our system does all that control and prioritisation automatically, tailored by customer type.

Another innovation is the ability to pick items directly into customer delivery containers. The software will track partially picked orders, strategically store and retrieve them, and balance workloads throughout the day. When an order is ready, the bot fetches it for dispatch, ensuring maximum fill and efficiency. All of this is coordinated seamlessly by our unified platform.

What makes your system so powerful for traceability and compliance?

Every product in pharma comes with strict requirements. You’ve got temperature control, batch and lot management, expiry tracking, full traceability from source to delivery. Managing all that manually introduces risk and cost. Our strength lies in our end-to-end scanning. Absolutely everything gets scanned, we know in a system like this the location of every single item, every single step of the way. Orders, whether destined for large hospitals, clinics or smaller pharmacies, are tracked with intelligent lot tracking, adjusting for different packaging sizes and picking requirements.

Incidentally, the sector is moving from older 1D barcodes to GS1-compliant 2D barcodes. That greatly improves traceability and helps with regulatory compliance and the systems we have (including McKesson) already support this.

What’s your main advice for pharma companies considering automation?

Automation enables high volume, high accuracy fulfilment, all the while maintaining full product integrity and compliance. Every unit, every pack, every case, can all be tracked from the point of induction into storage all the way through to dispatch, providing complete visibility and traceability.

However, there’s no single blueprint for automating a pharma operation. Every site has its own mix of product types, order patterns, regulatory requirements. Remember, you’re not choosing a vendor, you’re choosing the operating model that will determine your speed, your cost, your compliance and your resilience for the next decade.

We’ve helped McKesson Canada consolidate seven separate zones into one unified platform. This is going to empower McKesson to more than double its productivity, which honestly is phenomenal, and that’s the level of improvement automation can deliver when the hardware and the software are fully integrated.

To see Ocado’s advanced automated warehouse technology in action and hear more from Andy Ingram-Tedd, watch the webinar available below.