Iovance Biotherapeutics’ Cell Therapy Center (iCTC) for tumour-infiltrating lymphocyte (TIL) therapies is located in Philadelphia, US.

The commercial-scale hub was greenlit in May 2019 when the US-based biopharmaceutical company signed a lease for the site.

Construction began the following month and wrapped two years later, with the facility officially opening in September 2021.

Iovance Biotherapeutics invested $125m towards the development of iCTC. At full capacity, the facility offers regional employment opportunities to more than 100 individuals.

In February 2025, Iovance announced that it had begun expanding the iCTC campus, aiming to supply TIL therapies to over 5,000 patients annually in the coming years.

Iovance has obtained a letter of intent from the Philadelphia Industrial Development Corporation (PIDC) for a five-year option to obtain additional space to increase the capacity of the facility.

Location of Iovance Cell Therapy Center

Iovance Biotherapeutics’ Cell Therapy Center is located at 300 Rouse Boulevard, beside the Central Green Park at the Navy Yard in Philadelphia.

Spanning more than 1,200 acres, the Navy Yard is a former military facility redeveloped as a customisable space for corporate, residential and research and development (R&D) communities.

The site was strategically chosen for its proximity to several airports, which enhances the delivery of TIL cell therapy to treatment facilities.

The company leased 136,000ft² (1,2634m²) of commercial space to construct the new facility.

The site was designated as a Keystone Opportunity Improvement Zone, which offers incentives for business development. The company has received financial incentives from the Commonwealth of Pennsylvania, the City of Philadelphia and PIDC.

Iovance Biotherapeutics’ iCTC details

The iCTC is designed as a centralised manufacturing facility that utilises modular processes to improve the scalability of TIL products.

The facility comprises a single-storey cGMP building with an adjoining utility yard and a three-storey office and laboratory building that incorporates adjacent green spaces and external retention basins, along with 318 outdoor parking spaces.

The building includes medical labs and dedicated processing rooms, ensuring aseptic handling throughout the entire operation and effective control against cross-contamination.

It enables the company to manufacture products according to the US Food and Drug Administration (FDA) guidelines. The iCTC also adheres to good manufacturing practices (GMP).

The design of the iCTC incorporates substantial redundancies, ensuring its operational capacity throughout the year while helping to improve the company’s internal production capabilities and reduce the cost of operations.

Technology details at Iovance’s iCTC

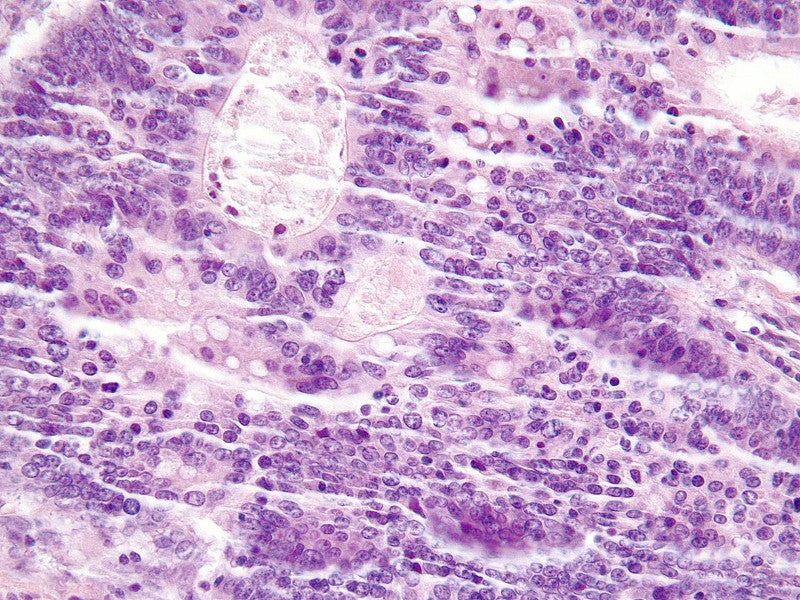

Iovance uses its proprietary Generation 2 (Gen 2) manufacturing process for the manufacturing and development of TILs for targeting heterogeneous solid tumours. The process has shown efficacy in melanoma, cervical, and head and neck cancers.

The technology is based on the natural TILs present in the human body, which target specific antigens related to a particular tumour. It was originally developed by Dr Steven A Rosenberg at the National Cancer Institute (NCI).

At the iCTC, the production process is patient-specific, with each product being uniquely crafted from the starting material of an individual patient.

The TIL cells are isolated from the patient’s tumour and are cultured and increased in number through tissue culture by stimulating them with interleukin (IL) 2.

The Gen 2 manufacturing process takes approximately 22 days to produce the final product, which is cryopreserved and shipped to sites across the US and Europe.

The potent and highly activated TILs are re-infused into the patients after preconditioning them to reduce the immune response after the therapy.

Incorporating the principles of Pharma 4.0, the company has created a chain of custody (COC) software system to meticulously monitor the journey of a patient’s sample from the hospital to the iCTC facility, through each stage of the production process.

Additionally, the facility includes a comprehensive electronic batch record system, coupled with continuous and centralised surveillance of every piece of equipment, ensuring a robust oversight of the production environment.

Environmental and sustainability details

The iCTC is Leadership in Energy and Environmental Design (LEED) certified, featuring environmental monitoring systems that are compatible with the advanced integration capabilities of Pharma 4.0.

The site incorporates a stormwater retention facility, with the entire courtyard area serving as a bioretention basin, with roof runoff being directed into this basin.

The iCTC’s planting scheme promotes biodiversity and provides habitats, utilising native and adaptive species that are primarily attractive to insects and birds.

Native trees, shrubs, and other plant varieties have been carefully chosen to flourish in an eco-rich landscape, offering the dual benefits of being low-maintenance and suitable for a dynamic floodplain environment.

Contractors involved

The facility was built by real estate company Gattuso Development Partners and design and construction management company CRB.

Law firm Morgan Lewis was the adviser to the company for facility development while real estate services company JLL advised on the lease transaction.

Construction management company Penntex Construction served as the lead construction manager for the facility, and landscape architecture studio Ground Reconsidered served as the landscape architect.

Environment and design company Digsau, landscape architecture and construction management company Synterra, Ensemble Real Estate Solutions and Investments, Graboyes Commercial Window Company, Leed Himmel Industries, Hatzel & Buehler and Pennoni were some of the other companies involved in the project.