Vetter’s Skokie Site Successfully Manufactures Batches on New Clinical Syringe Filling Line

International contract development and manufacturing organisation (CDMO) specialising in aseptic filling Vetter has announced that its new clinical syringe line has manufactured a double digit number of batches for use in early clinical trials.

The line is part of growth expansion activities at the company’s Skokie facility, which has been undertaken to help satisfy growing customer demand. It also includes an increase in storage designed to help manage the continued growth in syringe fills and overall larger batch sizes.

Since the beginning of full operations in late 2011, Vetter’s clinical manufacturing facility at the Illinois Science and Technology Park in suburban Chicago has been expanding to meet growing customer demands. Recently, this included six new chest freezers, two upright freezers, and two refrigerator units. As a result, storage will be expanded by the end of the year to increase capacity by 150%.

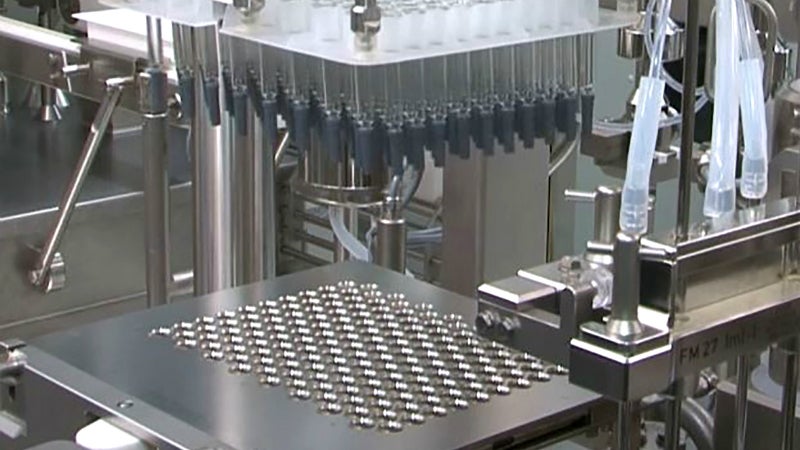

In addition to the many clinical batches filled for customers in vials, both for aseptic liquid and lyophilised products, the solution provider has successfully launched an aseptic syringe filling line.

President of Vetter Development Services USA Dr. Susanne Resatz says: "Year to date, a double digit number of clinical batches have been manufactured for customers and we anticipate a significant increase in the number of batches in the coming years".

This reflects the trend the company sees through its continuous dialogue with new and existing customers, as starting syringe work in the early clinical phases can cut up to 18 months off time-to-market.

She adds: "Given our experience at this facility with filling and lyophilisation, many of our customers are returning for development work for a second, third, or even fourth molecule. As a result of this, our outlook for future performance is very positive as demonstrated by a solid pipeline filled with high-quality customer projects for biologics".

Vetter’s Skokie facility is the company’s US clinical manufacturing site, providing development support for preclinical through phase II injectables, primarily complex biologics. The facility, currently operating with a growing staff of more than 60, has solid experience with a variety of complex compounds, and has already made more than five transfers to the company’s European commercial facilities to prepare for commercial launch, with more to follow in the near future.

The site offers all the resources needed for efficient early-stage clinical manufacturing, including chemical analysis and microbiology labs, material preparation, and compounding functions. At the heart of the facility are its cleanrooms, followed by visual inspection capabilities and good manufacturing practices (GMP) storage.

The facility has collaborated with pharmaceutical and biopharmaceutical companies from various continents including the US, Europe, Asia, and the Middle East.