HVAC and Cleanroom Design: ZETA Is Expanding Its Service Portfolio

Acting as a one-stop-shop for its customers in the pharmaceutical and biotechnology industries and meeting all their requirements is a top priority for ZETA. The Austrian company is now expanding its service portfolio with innovative services, as well as a new team of fifteen HVAC and cleanroom design experts.

High quality and safety standards are fundamental criteria in the planning and development of production facilities for the pharmaceutical and biotech companies. Building services engineering aspects are no less significant, however, and demands in this field have been increasing steadily over the past few years. HVAC (heating, ventilation and air conditioning) is a central factor in this context and is subject to strict regulations, in cleanrooms, in particular.

Cleanrooms in pharmaceutical and biotechnological production processes minimise the airborne particles either introduced into the room or generated there. Simultaneously, the precise number of these particles, and also the germ count, are closely monitored, because any deviations can harm production. Meeting these exacting standards requires powerful and precise HVAC systems that create optimum conditions for particle and germ-free cleanrooms.

ZETA is your one-stop-shop partner

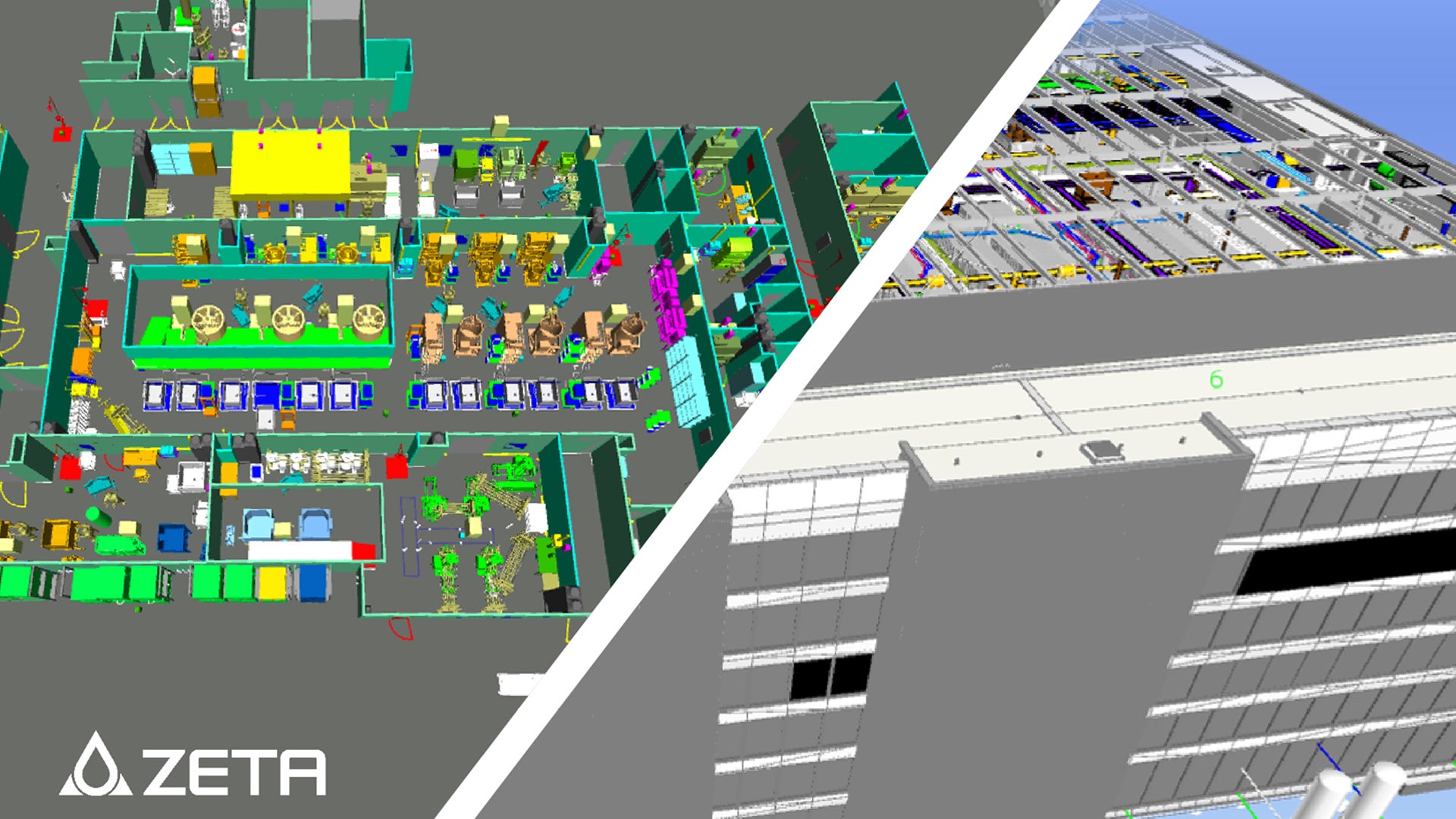

With this in mind, the engineering specialist ZETA expanded its service portfolio to include HVAC and cleanroom design, provided by a new team of 15 highly qualified experts.

ZETA managing director, in charge of production and technology, Alfred Marchler explained: “The demands heating, ventilation and air conditioning must meet in the pharmaceutical and biotech industries have increased significantly in recent years. This is why it is of central importance to have process plants and technical buildings services planned, designed and built in a totally coordinated manner.”

The new team adds to ZETA’s expertise as a one-stop-shop for the pharmaceutical and biotech sectors.

Marchler further explained: “In addition to the end-to-end planning and design of the process systems from concept stage to detail engineering, ZETA is now able to also offer expert planning of cleanrooms and ventilation systems. This means we can ensure the perfect alignment of process system and technical building services, ie ZETA is able to tailor cleanrooms perfectly to its customers’ demands.”

For more information, please fill out the enquiry form attached to this page.