Christ Packing Systems Receives Patent For Innovative Sealing Technology tn The FilmTeq 250 Stretchbanding Machine

Christ Packing Systems GmbH & Co. KG, a leading manufacturer of packaging machines for the pharmaceutical and medical device industries, has been granted a patent for the newly developed sealing unit of its FilmTeq 250 stretchbanding machine. This award-winning technology marks a milestone in the advancement of end-of-line packaging and was specifically designed to meet the demanding requirements of the pharma and medical device sectors.

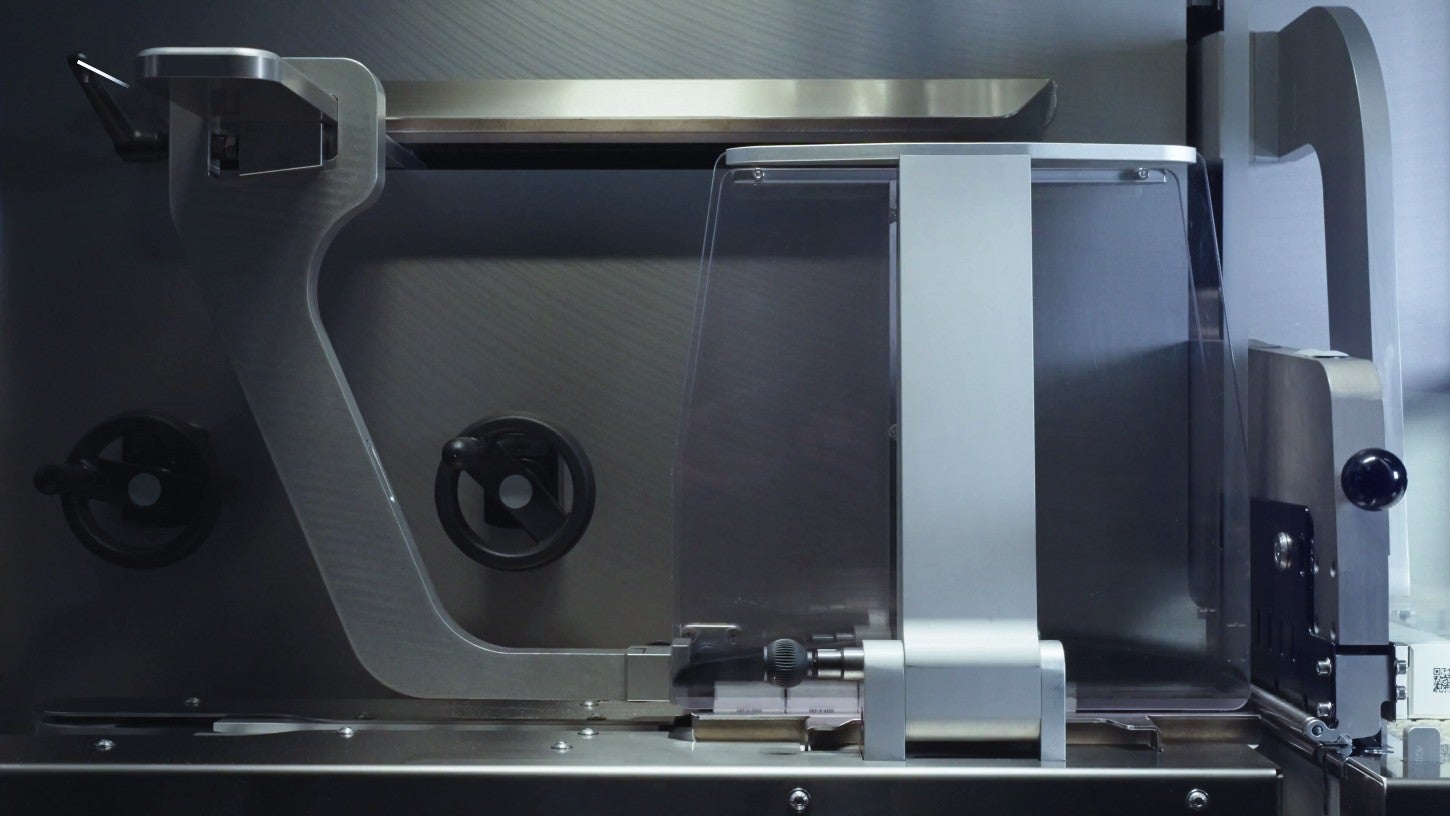

Top-down sealing: setting new standards in sealing technology

Conventional stretchbanding machines seal the film from below, which results in undesired heating of the sealing table. This leads to several disadvantages, including product heating, the need for extensive cooling, and increased mechanical complexity. In contrast, Christ Packing Systems’ patented solution uses an innovative top-down sealing process. This means that no heat is introduced into the sealing table, preventing product heating and reducing the need for complex cooling systems.

At the same time, the process allows for a much more compact machine design with a smaller footprint – a clear advantage for modern production environments.

Mechanically synchronised sealing and clamping motion for higher efficiency

A key feature of the new sealing unit is the mechanically synchronised movement of the sealing and clamping bars. The entire unit is powered by a single servo motor, which not only simplifies machine control but also significantly shortens setup times. The precise, synchronised motion also ensures consistently high-quality seal seams, which is a crucial factor in highly regulated industries like pharma and medical devices.

Sustainability through extended component lifetime: reversible plates

The patented sealing unit includes a “reversible plate” function, allowing both the sealing and clamping bars to be used twice. By simply flipping the bars, their lifetime is doubled – reducing downtime, spare parts consumption, and contributing to overall sustainability.

Statement from Jörg Aurbacher, managing director of Christ Packing Systems: “Our development combines several key benefits: less complexity, easier operation, higher seal quality, and greater sustainability. With this, we are setting new standards in stretchbanding for the pharmaceutical industry and helping our customers succeed in a highly competitive market.”

Video showcases technology in action

To illustrate the new sealing unit, Christ Packing Systems provides a video that demonstrates the functionality of the FilmTeq 250 and the advantages of the patented solution. The video is available at [https://youtu.be/12tNE29V3uQ].