Join SEPHA at ProPak Asia

Sepha will debut two of its innovative range of non-destructive leak test machines at ProPak Asia in Bangkok.

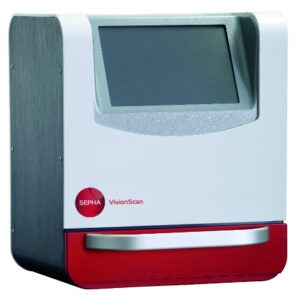

Taking place from 12–15 June, ProPak Asia will see demonstrations of the Sepha VisionScan and Sepha Multi-Q, which will be available at the booth of agent KTBel #AG39 in Hall 98.

The Sepha VisionScan is a small, non-destructive, tool-less leak test solution for pharmaceutical blister packs. The machine uses a combination of imaging technology and differential pressure and can detect leaks in individual blister packs down to seven microns (pack dependent). It offers pharmaceutical manufacturers a cost-effective alternative to methylene blue dye testing as the blister packs aren’t destroyed during testing enabling product to be returned to the production line.

The non-destructive method provides reliable, objective and deterministic results. And as the machine doesn’t require tooling, it’s ideal for production lines running multiple products.

The Sepha Multi-Q is a multi-functional leak test device, designed to operate in combination with different testing methods aimed at testing the integrity of different pharmaceutical containers. Testing methods that are compatible with the Multi-Q are:

- Vacuum decay – Utilises the ASTM F2338-09 (2013) test method to test vials, ampoules, bottles, pre-filled syringes, blow filled seals, medical devices and trays. The non-destructive, deterministic leak test device can identify leaks and channel leaks as low as 5µm and gives a pass/fail result in 10 seconds

- Pressure decay – Non-destructive, reliable and repeatable test method, ideal for testing the integrity of lyophilised and liquid filled vials, ampoules, bottles and other containers. The device shows a pass/fail result in 10 seconds and can identify leaks and channel leaks as low as 5µm

- Flexible Membrane – Non-destructive, tool-less leak detection device designed for flexible or semi-flexible packaging. Using hybrid membrane technology, the flexible head utilises the ATM F2338-09(2013) test method to perform the leak test. Ideal for testing gross or micron holes in pouches, sachets and bags that contain tablets, capsules, powders or devices

These non-destructive and deterministic test methods provide quick, reliable and repeatable results enabling customers to improve the accuracy of their leak detection procedures and reduce cost as the method prevents the packaging from being damaged.

To see a demo of the machines, visit us at the KTBel booth #AG39 in Hall 98 at ProPak Asia.