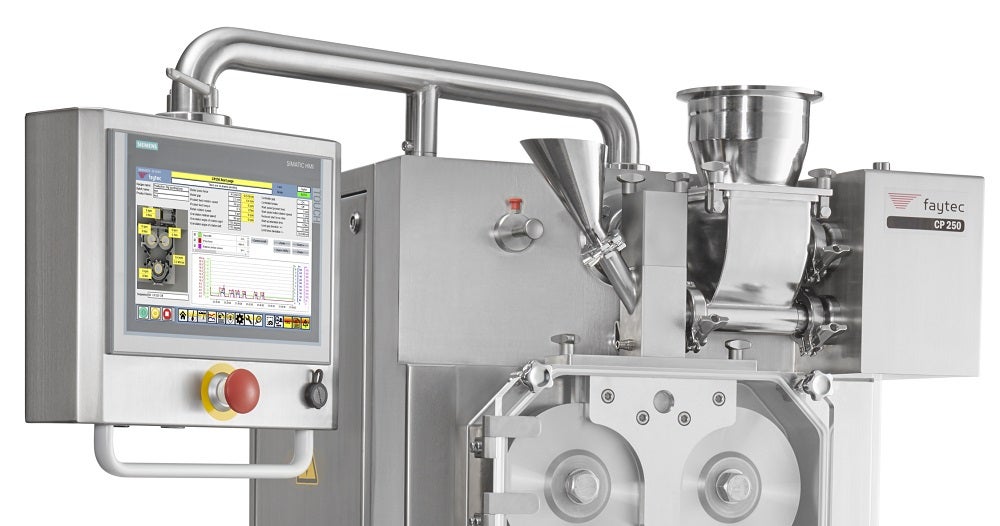

FAYTEC is a Swiss manufacturer of high-quality roller compaction technology for optimum dry granulation solutions for the pharmaceutical industry.

Founded in 2010, the company specialises in innovative roller compactor design.

Combining extensive knowledge and high flexibility for clients’ projects, we aim to meet the needs of our customers and adapt our systems with intelligent solutions.

Dry granulation technology for the pharmaceutical industry

Due to lower production costs, the straightforward and rapid process of roller compacting against wet granulation is becoming more renowned. We offer fully programmable logic controller (PLC) automated and sensor-controlled roller compactors to increase the production performance while retaining high quality.

We equip all our roller compactors with an efficient de-aeration system that enables the compaction of materials with low bulk density. The variable press roller gap control in full automatic run modus help to maintain the quality during the compaction process.

Continuous compact and granulating processes, together with direct handling and short cleaning time for a product change, are responsible for the reasonably priced product manufacture.

Large production roller compactors for dry granulation

The CP 1000 is FAYTEC’s top highend and largest roller compactor. The device has a throughput of up to 400kg an hour and its granulator rotor measures 250mm in diameter.

The rollers apply constant pressure, together with a variable roller gap controlled precisely by a hydraulic system, to ensure the density of the pressed strip stays constant.

There is enough space underneath the roller compactor for containers of up to 200l.

Press roll cooling for temperature-sensitive loads

The CP 1000 can be equipped with press roll cooling for when preparing temperature-sensitive products. All metering screw units can be disassembled or extended easily for quick cleaning.

The roller compactor has a transparent security door, allowing users to monitor the whole production process.

Wash-in-place for dangerous pharmaceutical substances

Many newly active pharmaceutical ingredients (APIs) are highly toxic. Therefore, we have an option for wash-in-place (WIP) of these substances.

WIP is an ideal solution for protecting both the user and the working environment.

Roller compactor powder feed systems

Two metering screw feeding systems for all FAYTEC roller compactors are responsible for the efficient vertical powder feeding of the press roller.

To avoid powder jamming when feeding the product to the process chamber, the metering screw of our roller compactor always has the same diameter and can, therefore, run at the same rotation speed. This feeding concept, coupled with sophisticated air deaeration, guarantees a constant powder feed to the press rolls without air inclusion.

Network connection for roller compactors

FAYTEC manufactures all roller compactors with the latest technology, easily connected to our clients’ networks, connections, batch protocol and alarm history, as well as audit list, back-up, open platform communications (OPCs) and much more.

The CP 1000 roller compactor can be connected via an RJ45 network to the machine supplier. Its optional process analysis tool (PAT) offers high-quality data processing and the controller can process data according to CFR 21 / part 11 (Audit Trail).

To book a technical consultation or find out more about what FAYTEC can offer, please use the enquiry form attached to this page and one of our representatives will be in touch.