Telstar Integrates New Soft Sensor Technology to Monitor Global Batch Product Temperature During Primary Drying in GMP Industrial Freeze-Dryers

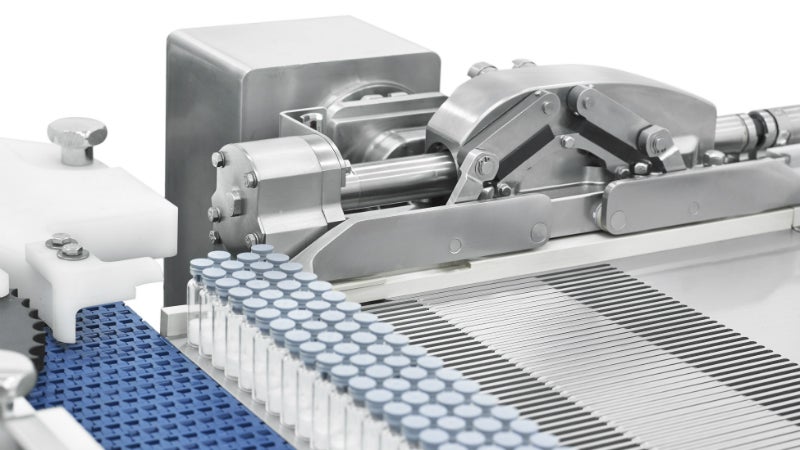

Telstar has incorporated an innovative soft-sensor temperature monitoring system in the new good manufacturing practice (GMP) industrial freeze-dryers with automatic loading / unloading systems.

Lyometrics is a new non-invasive monitoring technique enabling measurement of interface temperature during primary drying under developmental or full production conditions, collecting more accurate, complete, and reliable information, rather than physical probes.

Unlike classical temperature gauges, the new development utilises a soft sensor technology that provides on-line monitoring of the global batch temperature without the limitations and interferences imposed by physical probes, which, as a consequence of its obliged physical location within the vials, are becoming progressively unreliable and impractical as levels of automation and containment increase.

The new soft-sensor solves the limitations offered by the most common tools used to acquire product temperature which are thermal probes, namely resistance temperature detectors (RTD) thermocouples or wireless probes. These physical probes have certain drawbacks and are not reliable in reflecting product temperature. Their presence within the vials can modify the process itself, and may also influence the stopper position and consequently the drying conditions in comparison to neighboring vials, which do not contain probes.

In addition, their physical size and location within the vial only permits meaningful measurements of the some vials, unlike the new system which offers online monitoring of the global batch temperature during the primary drying without the limitations imposed by physical probes.

Furthermore, Lyometrics can obtain reliable and accurate information related to the ice temperature at the sublimation front, one of the most critical parameters in freeze-drying processes. The new software system installed within the control system of a freeze dryer enables the determination of the average sublimation interface temperature of an entire product batch, unlike static physical probes which cannot measure this because of the continuous motion from the upper surface of the product to the lower regions whilst drying progresses.

The Lyometrics system, fully developed by Telstar, is applicable to production environments and is particularly useful in situations where automation and physical barriers make the use of physical probes impractical.