BioCentriq is a clinical manufacturing facility for cell and gene therapies located at the New Jersey Institute of Technology (NJIT) university in Newark, New Jersey, US. It is the first cell and gene therapy development and manufacturing centre established on a university campus in the country.

The manufacturing centre, also the first such facility in Newark, was developed by the Biopharma Division of NJIT’s New Jersey Innovation Institute (NJII).

It is housed at NJIT’s Life Sciences and Engineering Centre and came after the opening of BioCentriq’s centre for process development at the Rutgers Medical School in Newark in 2019.

The cell and gene therapy process development and clinical manufacturing centre was inaugurated in October 2020.

Details of BioCentriq cell and gene therapy manufacturing centre

The advanced therapy development centre is located on the top level of the Life Sciences and Engineering Centre. It complies with the standards of the US Food and Drug Administration (FDA).

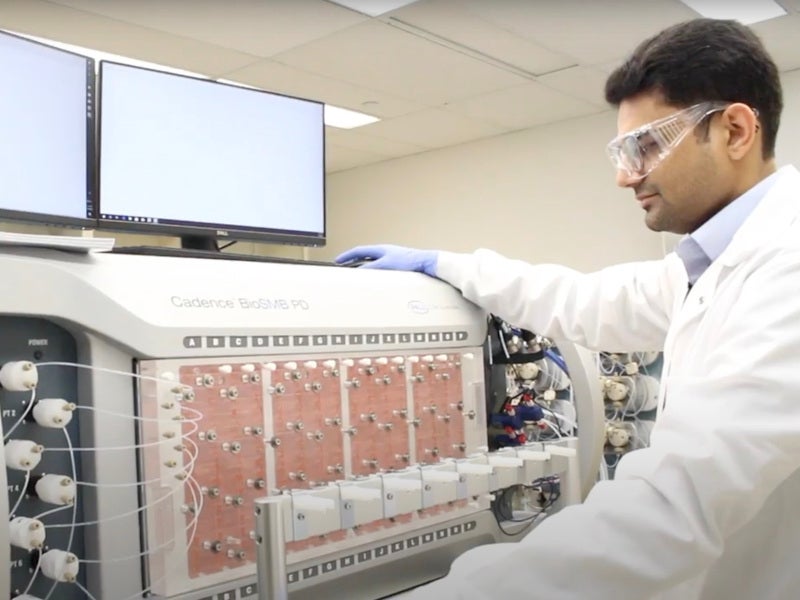

The current good manufacturing practice (cGMP) facility of the process development and clinical manufacturing organisation (CDMO) features process development, automated stations for clinical manufacturing, analytical test centres and advanced quality systems.

It includes two controlled-access ISO 7 cGMP suites, one each for the clinical production of cell therapy and gene therapy. A pilot plant dedicated to therapy process development has also been created to increase the production of cell and gene therapy products.

GMP suites are installed with dedicated heating, ventilation and air conditioning (HVAC) systems and have the capability to process multiple samples. The suites and cryo-storage lab are supported by a live monitoring system, uninterruptible power supply (UPS) systems, and a back-up generator.

The suite designed for cell therapy has a US Food and Drug Administration (FDA)-compliant manufacturing execution system (MES) to document and track the processing of products. Two Grade B cleanrooms have also been provided, including five laboratory benches.

BioCentriq also offers workforce-development programmes to improve skills of students and future workforce by partnering with leading pharmaceutical industries, training institutes, the US Federal Government and funding agencies, such as the National Institute for Innovation in Manufacturing Biopharmaceuticals (NIIMBL).

The programme aims to offer custom and general training to prepare the workforce with the skill sets required for the manufacturing of biologics and cell therapy.

Products and services

BioCentriq supports the development and optimisation of cell and gene therapy products by involving a dedicated team of scientific experts in that particular field. Included factors in optimisation are vector selection, cell growth and yield.

Types of cells covered are natural killer (NK) cells, T-cells, T-NK cells, stem cells, antigen-specific T-cells and HEK 293.

The facility can replicate the research and development processes with transformation and optimisation. It can fast-track the production of clinical-grade material for investigational trials.

BioCentriq is also equipped with a dedicated single-use bioreactor production suite for viral vector manufacturing with a 200L production capacity.

It features suspension and adherent cell culture, formulation and final purified bulk production capabilities. Customers can use purification services provided through ultracentrifugation or chromatographic techniques.

Marketing commentary on NJII’s Biopharma Division

The Biopharma Division of NJII was formed in 2015 and includes BioCentriq and a programme for workforce development, as well as an incubator initiative known as BioFoundry.

The Biopharma Division is focused on helping the pharmaceutical industry overcome the challenges in the development of potential cell and gene therapies.

The incubator supports early-stage biotech companies in securing capital, mentor guidance and resources required for growth. BioFoundary has tie-ups with 33 universities in New Jersey, along with 3,000 connections and helped approximately 12 new start-ups.

NJII is a non-profit organisation that supports cell and gene therapy development and manufacturing through cooperation and transformation.