Every year, millions of disposable gowns end up in medical waste incinerators. But a new generation of sustainable textiles is changing that story.

Healthcare facilities are under growing pressure to reduce waste and demonstrate environmental responsibility. In a sustainable circular economy, this translates to developing products that can be reused rather than discarded after a single use.

According to the European Textile Services Association (ETSA), textile service providers are increasingly adopting circular systems in healthcare to reduce environmental impact and improve operational efficiency. Its Sustainability and Corporate Responsibility in the Textile Services Industry report outlines the sector’s commitment to circular, service-based models built on rental, reuse, repair, and recycling. The report also highlights transparency, lifecycle accountability, and data-driven benchmarking as key tools for aligning the textile services industry with EU circular economy goals and the European Green Deal. ETSA members pledge to minimise environmental impact through resource-efficient laundering, reduced emissions, and extended textile lifecycles, while upholding rigorous hygiene and labour standards.

A life cycle assessment published in the American Journal of Infection Control found that reusable isolation gowns consume 28% less energy, emit 30% fewer greenhouse gases, and generate up to 99% less solid waste than disposable equivalents. Hospitals adopting reusable systems also report substantial financial savings: Each use of a disposable gown produces medical waste that must be handled and incinerated at cost. Reusable systems eliminate most of that burden.

In 2023, a pilot programme across two hospitals, involving more than 200 clinical staff and over 600 operations, found that switching from disposable to reusable surgical gowns reduced around 170kg of solid waste in just a few months and delivered measurable cost savings per procedure. Staff satisfaction also improved significantly as confidence in the reusable system grew, from roughly a quarter of participants at the start to more than half by the end of the trial.

By 2030, medical textiles sold in the EU will need to be durable, repairable, and largely made from recycled fibres, criteria that Asiatic Fibre Corporation (AFC) already meets. The company’s AFC CIRCULAR™ range of surgical textiles replaces the high-waste culture of single-use garments with durable, recyclable alternatives. Healthcare facilities across the Americas, Asia, and Europe have already adopted reusable AFC textiles, with reported improvements in waste reduction and increased staff satisfaction. Clinicians reported improved comfort and reduced fatigue after long operations, and each piece is designed for longevity, lasting between 75 and 100 wash and sterilisation cycles, significantly cutting both material waste and long-term costs.

Technical performance and sustainability integration

Environmental measures must be implemented without compromising clinical protection. EN 13795 and AAMI PB70 are two of the most important international standards governing protective apparel used in surgical and clinical settings. EN 13795, established by the European Committee for Standardization (CEN), sets out detailed performance and testing requirements for surgical gowns, drapes, and clean air suits. It focuses on factors such as barrier resistance to liquid and microbial penetration, linting, cleanliness, and fabric strength, ensuring that textiles maintain safety and performance throughout their intended use and reprocessing cycles. AAMI PB70, developed by the Association for the Advancement of Medical Instrumentation in the United States, classifies protective garments into four levels based on their liquid barrier effectiveness, from minimal to high protection.

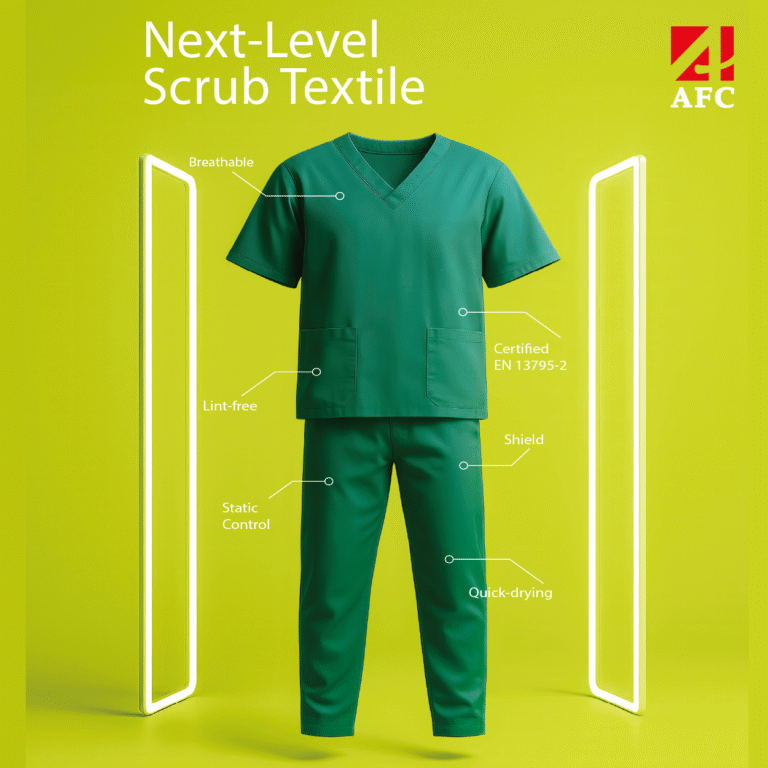

AFC’s surgical barrier textiles are rigorously tested and certified to EN 13795 and AAMI PB70 standards. The garments are also manufactured under an ISO 13485–compliant quality management system, the global standard governing the design and production of medical devices, to ensure that every stage meets strict regulatory and traceability requirements.

AFC’s barrier textiles are engineered from 100% microfibre polyester with embedded conductive filament yarn, providing electrostatic discharge control, enhanced tensile strength, and consistent barrier protection. Compared with traditional cotton or poly/cotton fabrics, AFC’s textiles demonstrate higher resistance to wear, superior fluid repellence, and stability across repeated wash and sterilisation cycles.

The AFC Circular system incorporates several eco-designed innovations:

- Recycled yarns to improve resource efficiency

- PFAS-free coatings to eliminate persistent fluorocarbons

- Dope-dyed fibres, which substantially reduce water and energy use during production

- Compliance with the EU Eco-design for Sustainable Products Regulation (ESPR) and the European Commission’s Transition Pathway for the Textiles Ecosystem

Ergonomics and user comfort

Beyond protection and sustainability, usability is becoming a key differentiator in next-generation medical textiles. AFC integrates ergonomic design and comfort science to meet the real-world demands of healthcare professionals. Healthcare professionals often work long hours in demanding conditions, where heat, restricted movement, or fabric discomfort can contribute to fatigue, distraction, and reduced concentration. Breathable, lightweight textiles that regulate temperature and allow freedom of movement help maintain focus, dexterity, and accuracy during extended procedures. By reducing physical strain and improving wellbeing, comfortable garments ultimately support both staff efficiency and the overall quality of patient care.

Traditional medical apparel often relies on dense or non-breathable fabrics that restrict mobility and trap heat. Resistance to Evaporative Heat Transfer (RET) is a measure of how easily perspiration vapour can pass through a fabric; the lower the RET value, the more breathable and comfortable the material. Textiles with values below 6 are typically classified as highly breathable, helping to regulate body temperature and reduce heat stress during long procedures.

AFC’s material engineers applied ergonomic design principles and moisture management technologies comparable to those used in high-performance sportswear. The C-R15 Air Scrub Suit is made from lightweight microfibre polyester with a moisture permeability (RET) of 2.54, offering high breathability and rapid drying.

Supporting circular healthcare systems

With more than five decades of experience in technical textile development and the production of over 50 million garments, AFC collaborates closely with healthcare providers and laundering partners to implement closed-loop textile management systems. Each garment is collected, disinfected, and reintroduced into service according to validated sterilisation and inspection protocols, reducing waste while maintaining product integrity and compliance.

This model enhances supply-chain resilience and transparency while supporting alignment with emerging EU sustainability frameworks. It demonstrates that clinical safety, operational efficiency, and environmental stewardship can coexist within a unified system of care.

As healthcare systems transition toward carbon-neutral operations, the adoption of reusable textile systems represents a practical and evidence-based route to reducing emissions and waste. AFC’s ongoing commitment to PFAS-free chemistry, recycled materials, and verified performance standards contributes directly to that transformation.

For more information on AFC’s circular textile solutions visit https://asiatic.com.tw/en/afc-circular/