by B Fretter (SDC) and H vom Bey (Gerteis).

Abstract

Press force and the gap between the press rollers are the main drivers in dry granulation, also known as roller compaction. Both influence the ribbon and granule properties. In general, a greater specific press roller force results in ribbons with higher density.

Depending on the material’s properties, the resulting granules are often coarser but generate mostly softer tablets. The impact of the gap is the opposite; a wider gap results in less densified ribbons, which lead to smaller granules and more robust tablets. The extent of this influence depends on the compacted material itself.

Introduction

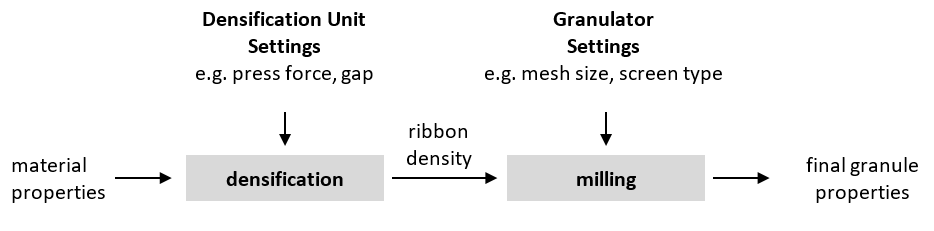

A roller compactor consists of three different functional units: the dosing unit, the densification unit and the milling unit. The dosing unit is responsible for providing material to the densification unit, which densifies the material between the two counterrotating press rollers into a powder band called a ribbon. The applied press force during roller compaction is called the ‘specific press roller force’, specified in kN/cm; the minimum distance between the press rollers is the gap [mm]. Force and gap are the main drivers affecting ribbon density in roller compaction.

Further, ribbon density is the main determining factor for granule properties. To understand the influence of press force and gap, ribbon density and granule properties must be under consideration. Additionally, the properties of the material, which is densified and milled, has a tremendous impact on the final granule properties.

Influence of the specific press force[kN/cm] in the roller compaction process

An example of the influence of the specific press force on the ribbon density is given in Figure 2.

Figure 2: Influence of specific press force [kN/cm] on ribbon density [g/cm³].

Starting from the initial bulk density at 0kN/cm, a greater press force results in ribbons with higher mass. The increase in weight is non-linear and flattens towards greater densities, as added force is required to densify the material.

Ribbon density influences granule properties, especially their re-compactability, which is the ability of the granules to generate robust tablets. As the material is densified once into the ribbon, the re-densification into a tablet is called ‘re-compaction’ or ‘second densification’. In Figure 3, re-compactability is shown for two different substances, depending on various roller forces; the impact of the press force is strongly substance-specific. While Microcrystalline Cellulose (MCC) shows a sharp decrease of achievable tablet strength, Lactose shows barely any impact. Most substances, which are roller compacted, show a specific loss in binding capacity because the bonding sites of the particles are used for making the ribbon. Nevertheless, both substances can achieve 2 MPa tablet strength, which is generally the target value for tablets.

Figure 3: Impact of the specific press force on the re-compactability of two different substances.

In addition to the re-compatibility of the material, the particle size distribution of the granule is affected by ribbon density. In general, a higher specific press force results in granules with coarser particles. In Figure 4, an example is provided for this relationship.

Figure 4: Example of the relationship of press force on the particle size distribution of granulates MCC in roller compaction.

Influence of the Gap [mm] in roller compaction

Besides the specific press force, the gap has a powerful impact on ribbon density. For a constant press force, wider gaps result in ribbons with lower density. An example is given in Figure 5, in which the ribbon density as a function of press force for two different gaps is displayed. For example, at an equal press force, the 4mm gap results in lower ribbon densities than the 2mm gap.

Figure 5: Example of the influence of press force and gap on ribbon density.

The thin layer model, described by Peter et al[1], explains the influence of the gap on ribbon density. A wider gap results in larger nip area, therefore the applied press force distributes over a greater area with less densified powder. The extent of this reduction depends on the densification properties of the material being compacted and cannot be generalised.

Consequently, roller compacting a material at the same specific roll force, but different gaps will result in different ribbon densities, leading to different granule properties, especially regarding the re-compactability and particle size distribution.

Comparing the extent of the influence of press force and gap on ribbon properties, the specific press force has a greater influence than the gap. Based on the example in Figure 5, doubling the force from 3kN/cm to 6kN/cm increases the ribbon density by approximately 31% (0.70g/cm³ to 0.92g/cm³) for the 2mm gap, whereas maintaining the press force and increasing the gap by a factor of 2 from 2mm to 4mm, the density is reduced by approximately 13% (for 6kN/cm: 0.92g/cm³ to 0.80g/cm³).

At higher specific roll forces, the impact of increasing the force gets smaller, as the material is already highly densified and further densification requires disproportionally higher press forces to achieve higher densification. The influence of the gap is also reduced at larger specific roll forces.

Conclusion

Constant press force and gap are the main influencing factors for consistent ribbon density and, therefore, for the granulate properties of re-compactability and particle size distribution. Whereas greater specific press forces result in higher ribbon densities, this is the opposite for the gap: wider gaps result in lower ribbon densities. The influence of the specific press force is greater than the influence of the gap. The extent of the influence depends on the properties of the material being compacted.