When developing a dry granulate with GERTEIS® roller compactors, trials are initially performed with very small amounts of material. Sometimes, the densification step for the small amount of material can also be simulated by a compaction simulator. Using conventional small lab-scale mills for milling the compacts results in different particle size distributions (PSD), as the functional principle cannot be compared to later production-scale roller compactors.

To allow more reliable predictions during early development, GERTEIS has developed a Small Scale Mill (manual mill) that eliminates the described difficulties. The GERTEIS Small Scale Mill inherits the same milling principle as the GERTEIS PACTOR® production machines, but generates PSD that provides reliable indications about the granule characteristics of future production, making it an excellent scale-up tool.

Influencing factors of the milling step on particle size distribution

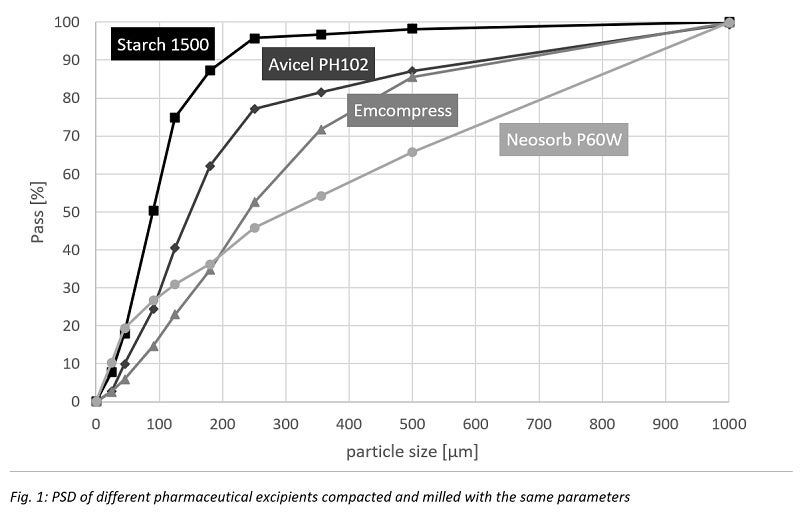

One important influencing factor on the PSD of granulates is, of course, the material itself, which is milled. Excipients, active pharmaceutical ingredients (APIs) and mixtures all have a significant impact on the PSD. An example for pure excipients is given in Fig 1.

Depending on the properties of the milled excipient material, major differences in PSD can be observed, and these impact granulate flowability. Milling a weak (softer) material results in smaller particles, whereas stronger and likely more dense materials will produce coarser granulates. Material properties such as plasticity, elasticity and brittleness also influence PSD.

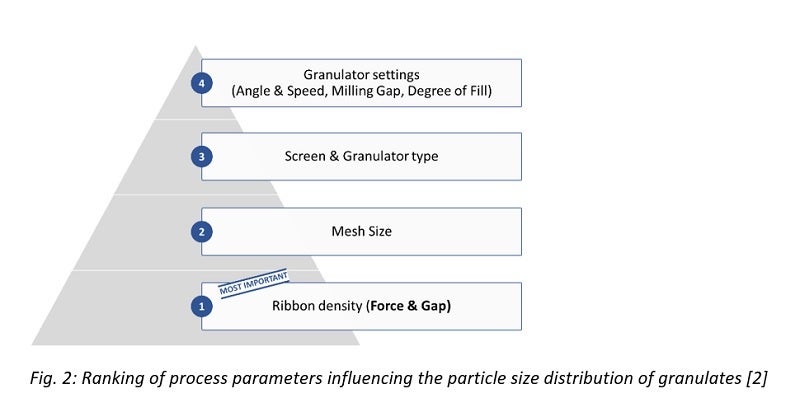

As well as the material or formulation, roller compaction process parameters can also affect the PSD of the granulate. Fig 2 shows a ranking of the influencing process parameter for roller compaction. The most important parameter is the ribbon density, which is a result of the specific roll force and gap used in the roller compactor. This applies to production roller compactors from GERTEIS in the same way as to lab roller compactors. A higher ribbon density, which is achieved by increasing the specific roll force, results in stronger ribbons and, therefore, larger particles (more details below).

Of course, the used mesh size also has an important influence on the final PSD because it limits the upper particle size. Using a smaller mesh size usually causes a shift towards smaller particles. This effect is more pronounced for the upper end of PSD rather than the amount of fines. During development, the influence of the mesh size is often examined. Other influencing factors include the screen and granulator type, as well as several granulator settings such as rotating angle and speed. These factors have the smallest impact on PSD.

How does specific roll force affect particle size distribution?

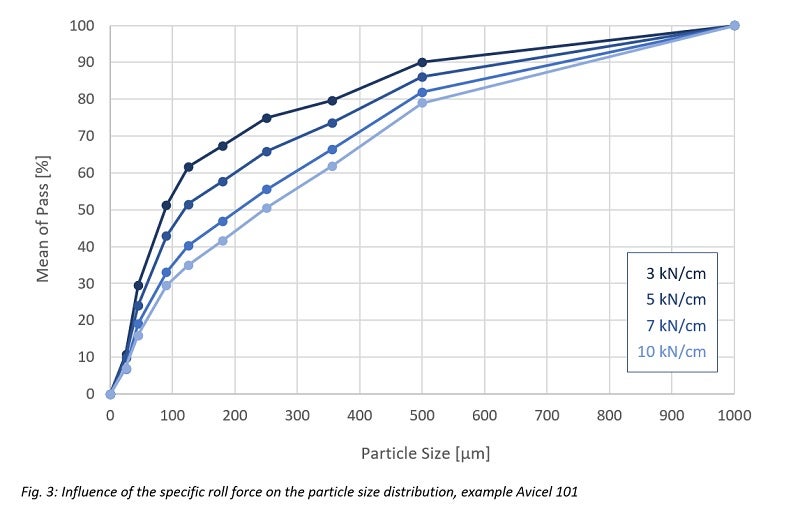

The influence of the specific roll force on PSD has the greatest impact on roller compaction granulate qualities and should, therefore, be the focus of development work for the dry granulation process. In Fig 3, Avicel 101 is used as an example of this effect. Increasing the densification by using higher specific roll forces results in coarser particles, although the width of their distribution remains constant.

At the upper range, PSD is limited by the mesh size. The largest shift in PSD can be seen for the middle-sized particles of 100-500µm. The impact on the amount of fines is nonetheless smaller, and the fines are reduced at higher roll forces during roller compaction. However, the extent of the influence of roll force depends on the pharmaceutical formulation being used ‒ it cannot be generalised.

Features of the GERTEIS Small Scale Mill

In some situations such as during development, when the API is rare or very expensive, it is desirable to be able to mill small amounts. Previous studies have shown that small lab or household mills are not suitable for achieving the same PSD as roller compactors for production. Because of this, GERTEIS developed a manually operated Small Scale Mill that can reproduce the grinding principles of the PACTOR line. The various wire mesh screens and rasping screens are interchangeable, which allows the user to mount different mesh sizes depending on their requirements.

The material ‒ either tablets or roller compactor ribbon pieces ‒ is forced through the screen by milling bars, which are operated manually. The material is then processed into the milling chamber and the final granules are collected in a drawer. Up to 50g of material can be milled in one pass, which is often enough for initial tabletting experiments. The manual mill’s overall design is intended to provide easy use so that mounting and cleaning of all parts is simple and fast. In addition, the material used for construction complies with all pharmaceutical requirements.

Comparing the MACRO-PACTOR and Small Scale Mill

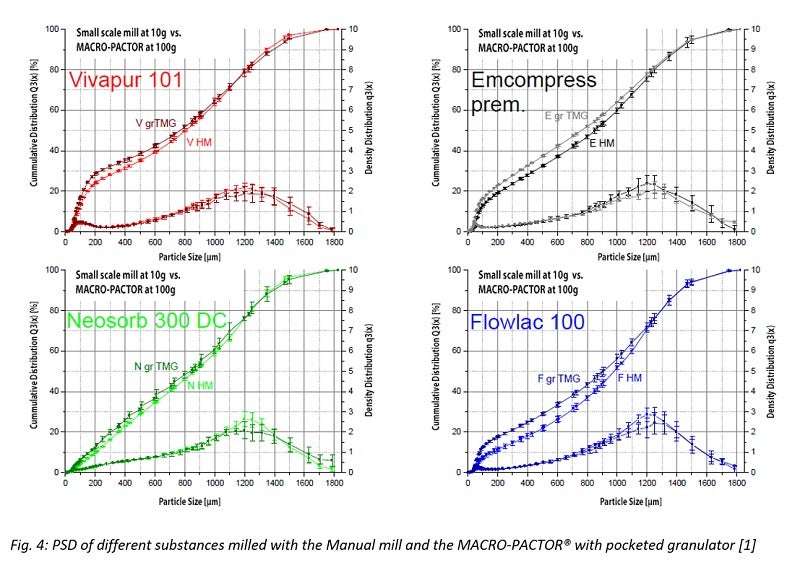

To evaluate the performance of the Small Scale Mill, four different excipients were tested. The same material in terms of densification and strength was milled with the Manual mill and the MACRO-PACTOR® (production scale roller compactor) equipped with the pocketed granulator rotor.

The results in Fig 4 show clear correlations between the granulates obtained by Small Scale Mill and MACRO-PACTOR for all four substances. All granulates follow the typical PSD of dry granulates, which is fairly broad. There are a certain amount of fine particles (particles below 100µm) present, but this is below 10-20%. Small differences between the Small Scale Mill and MACRO-PACTOR can be observed in the extent of the strongest particle fraction between 1,000µm and 1,400µm, which creates a slight shift in PSD towards coarser particles for the Small Scale Mill.

The extent of this small deviation seems to be material-specific. This is caused by the MACRO-PACTOR’s other process parameters such as granulator settings (as shown in Fig 2), which cannot be transferred to the manually operated Small Scale Mill. During scale-up, these process parameters will be optimised, meaning the small differences in PSD can be neglected during development.

From the results, it can be concluded that both the Small Scale Mill and the MACRO-PACTOR show almost identical PSD and that, therefore, the Small Scale Mill is ideal for milling small amounts of material to representative granulates.

Sources

1: Potschadl, J, PhD Theses, ‘Scale-down des Walzenkompaktierprozesses Entwicklung eines Trockengranulats im Kleinstmaßstab’, University of Bonn (2013)

2: Wiesweg, S, PhD Theses, ‘Einflussfaktoren des Walzenkompaktierprozesses auf die Partikelgrößenverteilung von Granulaten’, University of Bonn (2009)