Entecon

Powder Handling and Conveying Solutions for Pharmaceutical Process Companies

Entecon supplies bulk material and powder handling equipment for pharmaceutical process companies, designed to suit clients' needs.

Subscribed

You have successfully submitted your enquiry. Someone from our company will respond ASAP

About Us

Entecon manufactures bulk material and powder handling equipment for pharmaceutical process, food, beverage, chemical, and paint companies.

Our products include aero-mechanical conveyors, dosing feeders, automatic sack openers, bulk bag filling stations and dischargers, and sack tip stations.

We offer custom-built systems to suit customers’ installation and specific product characteristics based on minimum lifecycle costs, reliability, production efficiency and safety.

Conveying solutions for bulk materials

Entecon offers customers the best powder handling conveyors for their applications and layouts, and for the flowability and cohesive character of their bulk materials.

Our conveyor systems are manufactured to high standards of quality, ensuring long working life with minimal need for maintenance. Entecon conveyors are custom-built to suit specific site conditions and applications, taking the characteristics of the material being handled into account.

Our conveying programme comprises aero-mechanical conveyors, solid screw conveyors, flexible spiral conveyors and pneumatic (vacuum) conveyors.

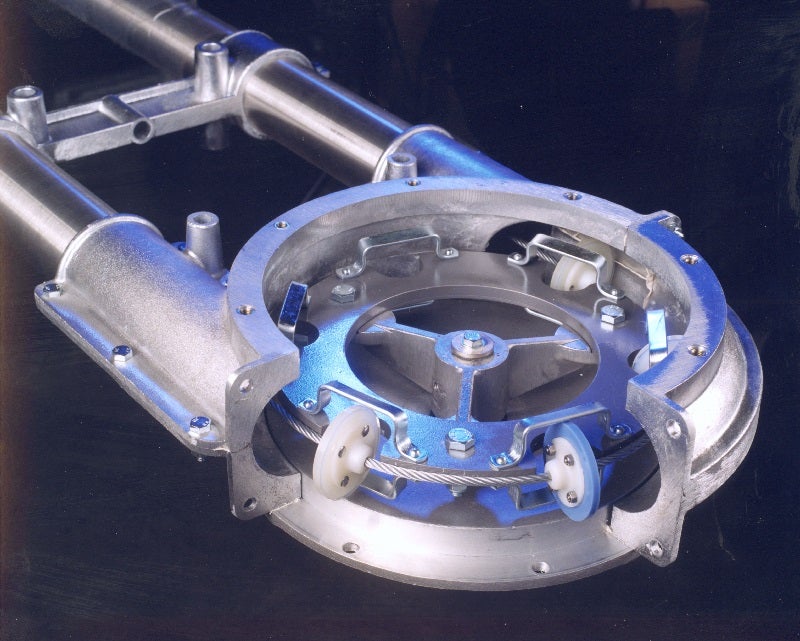

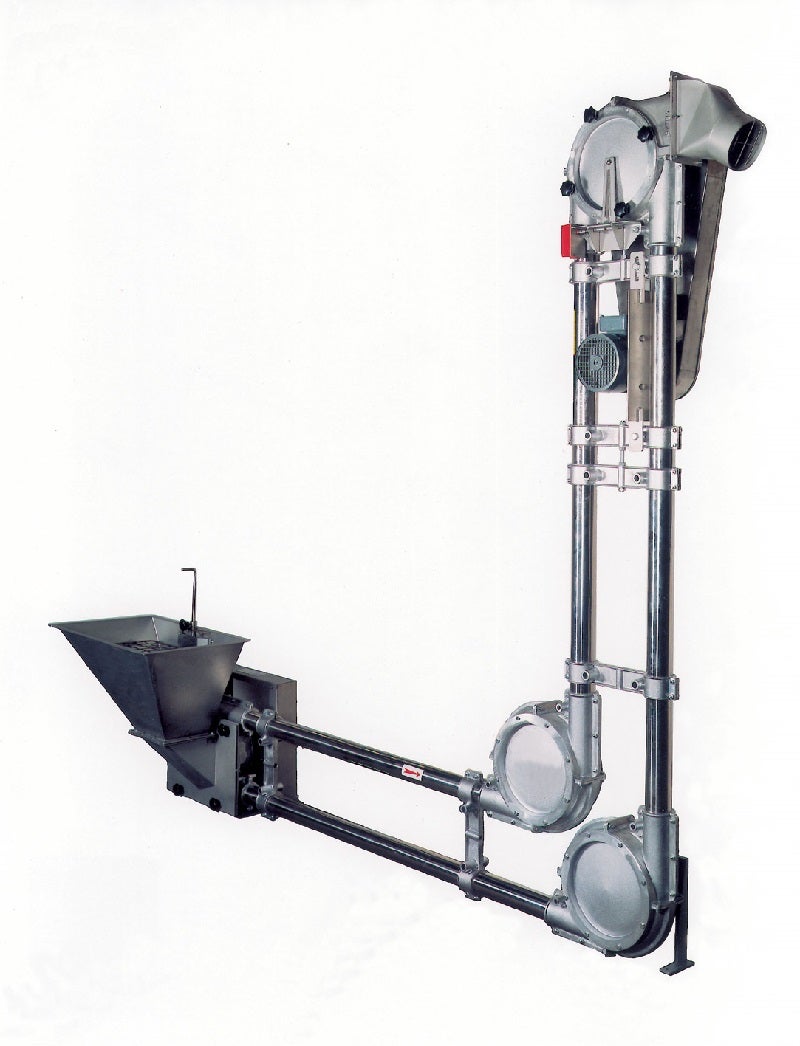

Aero-mechanical conveyors

Aero-mechanical conveying was introduced to the UK market by Entecon in 1963. Since then, thousands of these systems have been sold throughout the world to handle powders and granular materials cleanly, efficiently and in an enclosed environment.

Entecon conveyors are built to endure conditions in which materials may contain particularly abrasive or corrosive properties.

The fully enclosed construction helps to maintain a dust-free working environment as required by health and safety legislation, as well as energy-efficient running costs.

Equipment for full turnkey systems

The equipment offered by Entecon is often integrated into full (conveying) systems. We project manage and supply equipment for full turnkey systems requiring:

Conveyors

- Aero-mechanical conveyors

In-house powder conveying systems by airflow with no outside air. The conveying takes place in a tubular system that is sealed and completely dust-free. - Vacuum conveyors

Vacuum is used for hygienically conveying food, pharmaceuticals, and chemical dry powder products through dedicated tubes, with efficient layout and vacuum pumps eliminating the need for plant air. - Solid screw conveyors

Shaftless screw conveyors with a trapezoidal section ensure material is conveyed over the whole diameter of the conveyor. - Flexible screw conveyors

Conveyors with a tube diameter ranging between 40mm and 140mm suitable for the characteristics of the material being transported. Load capacity from 120kg/h to 10,000kg/h.

Sack openers

- Automatic sack openers

Highly safe, enclosed and efficient bag emptying stations for loading mixers and other processing equipment, capable of emptying up to 600 sacks an hour. - Manual sack tip stations

Hygienic solution for efficient and comfortable bag dumping.

Feeders

- Flexible dosing feeders

Universal volumetric and gravimetric feeders and discharge systems for many bulk goods, including powders, granules, flakes and fibres.

Big bag systems

- Big bag dischargers

Safe and dust-free flexible intermediate bulk container (FIBC) unloading stations for the complete and controlled emptying of big bags. - Big bag filling stations

Entecon’s heavy-duty bulk bag filling stations provide a dust-free method of filling all types of FIBCs.

Our full range of equipment is designed to CE machinery directives and supporting standards, ensuring long working life with minimal maintenance. For hazardous or explosive environments, ATEX certification will be supplied.

About Entecon

Since introducing the aero-mechanical conveyor to the market, Entecon has extended and developed its range of powder handling solutions and equipment with leading-edge technology.

Based in the UK and the Netherlands, the company continuously develops expert, reliable and safe bulk handling equipment for powders and granules, as well as hygienic solutions.

Contact Details

Website

Email Address

Address

Camberley, Surrey,

GU15 3DL,

United Kingdom