Optima Pharma to Present at Pack Expo and Pharma Expo

Optima Pharma has announced it will present at packaging trade shows Pack Expo and PharmaExpo, which will take place at the same time.

At Pack Expo, Optima Consumer will be celebrating the premier of the OptiPouch system. It will be combined with the new rotary filling machine and the rotary closing machine to create a complete, continuous process.

The OptiPouch system processes up to 600 spouted pouches per minute. Only one operator is needed to provide the machine with prefabricated pouches, which can range in type and size from 50ml to 500ml without the need to change parts.

Various options are also available to enhance the highly compact system with various hygienic and sterilisation functions, such as clean-in-place (CIP) or sterilisation-in-place (SIP), laminar flow with Hepa filters, and UV light.

Optima also implements complete solutions including secondary packaging and palletising. The spouted pouches help reduce CO² footprint and approximately 1.8 million empty containers are transported per truckload.

Optima Consumer will also provide information about packaging solutions for foods, cosmetics, and chemicals. The company’s packaging systems process a wide variety of products from low to high-viscosity, powder or granulate, and serving-size packages or large containers. Everything from coffee capsules to mascara sticks and oil canisters can be processed.

The packaging systems presented by Optima Nonwovens at Pack Expo for paper hygiene products contain state-of-the-art technologies. Combining control and outer packaging functions form automated complete solutions. Through Total Care Asset Management (TCAM), the company also provides service functions for the age of Industry 4.0.

Optima will present at Pack Expo in Chicago from 6 November to 9 November. Its stall will be in the North Building in Booth N-6121.

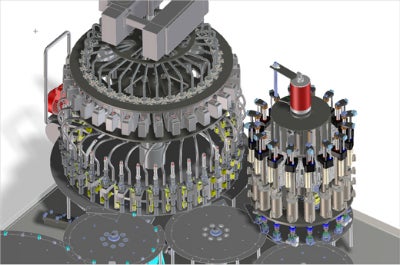

At Pharma Expo, Optima Pharma will be presenting details on its current turnkey projects in 3D using virtual reality. The exhibit will include large systems Optima Pharma has implemented, such as for filling and sealing under an isolator. In combination with freeze drying, various processing paths are available, which can be used in parallel.

Other systems for sterile processing of syringes, vials and diagnostic products will be shown in 3D, as well as the new, highly flexible Optima MultiUse Filler. This filling and closing machine is suited to laboratory applications and fully automated processing of small batches.

The system can process all types of nested syringe, vial and cartridge formats and is equipped with an innovative transport system, which processes large vial ranges at production rates of up to 150 products per minute without the need to change format parts. Its modular design gives the end-user flexibility for a quick response to all market and production demands.

Optima Life Science will also present the new OPTIMA TDC125 machine virtually at Pharma Expo. This machine manufactures transdermal patches (TDS) and oral filmstrips (ODF) on a laboratory or small-production scale. All production and packaging processes can be validated and later transferred to larger production machines if necessary. The scalable machine is suitable for manufacturing product samples for clinical tests, for market launch, and for subsequent production. In the simplest form the system operates intermittently. Alternatively, the system can be operated in a continuous mode with a high-output in series production. Both intermittent and continuous mode varients will be shown in 3D.

Optima Pharma and Optima Life Science will present at Pharma Expo in Chicago from 6 November to 9 November, 2016. Its stall will be in the West Building in Booth W-731.