The 3V TECH Group is a global supplier of process equipment and systems for the chemical, pharmaceutical and environmental industry. The Group is comprised of the following companies:

- 3V COGEIM: a market leader in solid-liquid and vacuum drying technology

- 3V MABO: a reference in the field of thin film and short path evaporation

- 3V GLASSCOAT: high-quality glass-lined equipment, with the most modern manufacturing plant in the world

- 3V GREEN EAGLE: a unique and self-developed technology for the treatment of wastewater and sludges

- SOFFIERIA SESTESE: components, equipment and plants in borosilicate glass 3.3

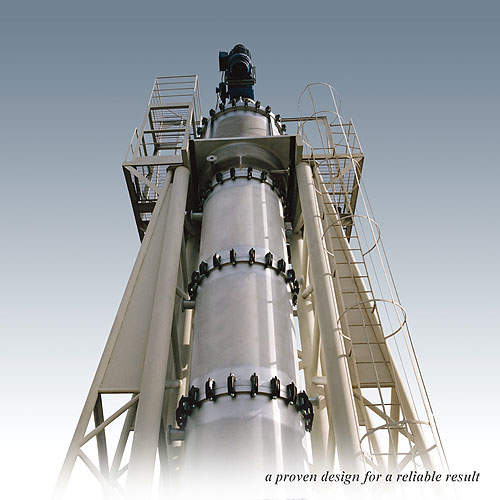

Filter dryers for solid-liquid separation

Solid-liquid separation can be obtained using pressure filters. In case drying is requested 3V COGEIM offers filter dryers that combine two process operations, filtration and drying, in the same equipment. The design can include:

- Fixed or removable bottoms with several closure options

- Various types of filter media

- Discharge systems suitable for wet or dry products

- Different agitator models

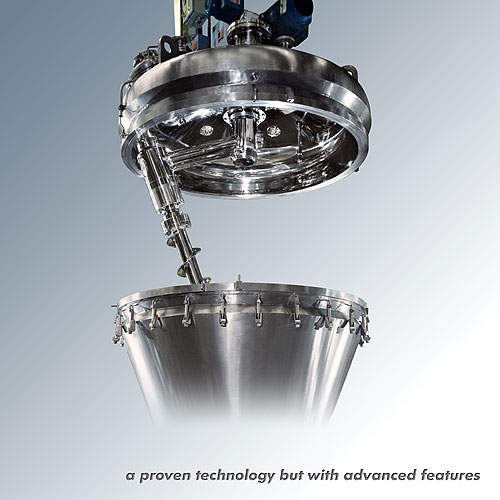

Vacuum dryers for batch production

In the area of batch production, vacuum drying is the most efficient method to dry filtered or centrifuged wet cakes. 3V COGEIM offers two different types of designs:

- Agitated vacuum vertical and conical dryers (pan dryers)

- Agitated, horizontal, vacuum dryers (paddle dryers)

3V COGEIM also offers equipment for continuous processes like the rotating pressure filter and semi-continuous processes like the leaf filter with centrifugal discharge.

Thin film and short path evaporation units and complete skids

Since the early 60s 3V MABO’s specialities have been thin film and short path evaporation units and complete skids, which allow the distillation of high-viscosity and thermo labile fluids under vacuum. The product range starts from small laboratory or pilot plant evaporators up to turnkey production plants with evaporation surfaces of 50m².

Specific process and technical expertise in this field, combined with a cost-effective manufacturing structure and the possibility to perform pilot tests in our pilot plant, makes 3V MABO a good choice for any evaporation challenge. Today 3V MABO is seen as a flexible and reliable partner in its sector.

Carbon steel glass-lined equipment

3V GLASSCOAT combines a state-of-the-art manufacturing plant with latest generation equipment, together with an experience of more than 50 years in this field, offering standard and tailor-made high-quality carbon steel glass-lined equipment, such as:

- Reactors

- Storage tanks

- Heat exchangers

- Double cone rotating dryers

- Filters

- Bottom outlet valves

- Piping

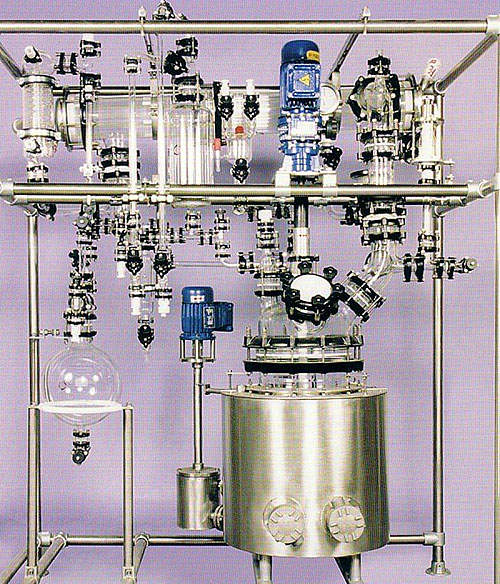

Furthermore, 3V GLASSCOAT has created a special glass-formulation which allows the glass-lining of stainless steel. This type of product, with an excellent internal and external cleanability, dead space reduction, and other features, has been designed for sterile pharmaceutical processes as well as for cryogenic applications (up to -140°C).

In order to complete its strategic vision as a global supplier, 3V TECH, in partnership with SOFFIERIA SESTESE, presents a modern and fully equipped glass factory: components and equipment in borosilicate glass 3.3 up to a nominal diameter of DN600, in a very high quality and fully interchangeable with most common flanged systems are offered at a cost-effective price.

The possibility to combine a glass-lined reactor from 3V GLASSCOAT with borosilicate 3.3 components (vapor column, condenser, piping) furthers strengthens the Group’s capabilities of supplying complete systems and packages.

Purification of wastewaters and sludges

3V GREEN EAGLE is specialised in purification of wastewaters and sludges from sewage treatment plants.

Our integrated treatment plant offers an in-house developed technology (TOP technology) of wet oxidation, certificated by IPPC as a best available technique (BAT). The TOP technology works in a continuous reactor at high pressure, high temperature and with direct injection of oxygen, converting non-bio-degradable components into bio-degradable components which are later treated in the biological plant.

The technology is multi-stream, as it works with a wide variety of contaminants. Furthermore, it is a zero emission technology, without the disadvantages of dioxin or small particles emission which we have when using other technologies such as incineration.

3V TECH can adapt this process to specific requirements anywhere in the world, supplying the complete process and turnkey plant.