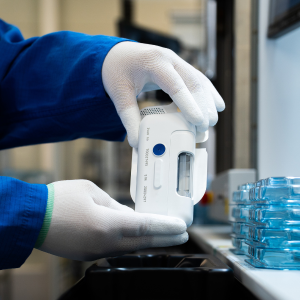

Clean Room Monitoring

Since product quality is often affected by the environmental conditions in a clean room, it is essential to monitor critical parameters such as particle concentration,temperature, differential pressure and humidity. In addition air flow (speed and direction) and door interlocking must be controlled.

Endress+Hauser provides the whole monitoring system,

incorporate sensors from your favored suppliers or simply add the Endress+Hauser monitoring system to existing equipment. In each case it offers a fully documented process according to GAMP 4/5, in accordance with FDA requirements to be GMP compliant.

Endress+Hauser’s clean room monitoring package offers five levels of sophistication:

- Level 1: data acquisition

- Level 2: visualization

- Level 3: data recording and qualification

- Level 4: data recording and SCADA software

- Level 5: rule 21 CFR part 11 compliance

Our project team accompanies and advises you from

concept to realization, ensuring a smooth passage through

qualifications and audits.

This includes specifically:

- Project management

- Basic, detail and implementation engineering

- Supply of measuring technology

- Complete monitoring system

- Qualification: design qualification

- Factory Acceptance Test (FAT)

- Commissioning

- Installation Qualification (IQ)

- Calibration of measuring points

- Operational Qualification (OQ)

- Training and instruction

Customer training, annual software assessment, recalibrations and instrument maintenance by Endress+Hauser service centers.