Benefits of Single-Pot Solutions for the Production of Pharmaceutical Granules

Pharmaceutical products such as ordinary or effervescent tablets are manufactured from powdery raw materials.

Lödige Process Technology (Lödige) offers high-quality customised machines, systems and services for process technology applications for mixing, granulating, coating, drying, reaction and related processes in the pharmaceutical industry.

You have successfully submitted your enquiry. Someone from our company will respond ASAP

Lödige Process Technology (Lödige) offers high-quality customised machines, systems and services for process technology applications for mixing, granulating, coating, drying, reaction and related processes in the pharmaceutical industry.

More than 500 patents and 35,000 machines and systems attest to Lödige’s experience with customer-oriented system solutions. The company operates with over 500 employees worldwide and supports its customers with a network of subsidiaries, technical offices and agencies.

Lödige has a subsidiary coordinating the entire North America business in Florence, Kentucky, US, as well as subsidiaries in Spain and France, and joint ventures in India and China. Additional licensees situate in Brazil and Japan, and worldwide representations complete the worldwide Lödige network.

Lödige has a broadly diversified international customer base, consisting of companies from the pharmaceutical, food and cosmetics industries, as well as construction materials, chemistry, metallurgy, cellulose, starch, minerals / ores and the environment.

The company’s customers appreciate the high quality of mixed products, together with the speed and efficiency of its machines individually tailored to the specific requirements of the respective industries.

As a solution and service provider for all processes, Lödige delivers sophisticated, bespoke operational subsystems and offers turnkey installations. The company assumes all work stages from set-up to installation and commissioning of the turnkey solution for the customer. As well as focusing on core industries, proximity to the client is key to sustainable corporate development.

In addition to the individual application-specific design of each machine, this calls for reliable customer service by experienced engineers ranging from the installation, subsequent upgrades and modernisation to dismantling and disposal, including emergency support in the unlikely case of a breakdown.

In-depth knowledge in processing for mixing, granulating, drying and coating systems forms the basis for the development of innovative system solutions for the pharmaceutical industry.

Lödige adapts perfectly to various on-site production conditions, enabling customers to master the challenges currently faced by manufacturing plants.

High-quality, cost-effective machines and services provided by experienced professionals make Lödige a valuable partner of the pharmaceutical industry, demonstrated by close long-term cooperation with well-known pharmaceutical manufacturers.

Across the world, the highest possible standards of safety, purity and reproducibility govern pharmaceutical production. Lödige’s products and services are subject to these same international quality standards.

In the context of this criteria, the company’s specific processing knowledge for mixing, drying, granulation and coating systems forms the basis of Lödige’s innovative system solutions for the pharmaceutical industry.

The customisable design of Lödige’s machinery conforms to all current good manufacturing practice (GMP) directives, US Food and Drug Administration (FDA) regulations and requirements for the production of wash-in-place (WIP) / clean-in-place (CIP) systems.

The company has developed close cooperation with leading pharmaceutical manufacturers and its expertise is regularly incorporated with the production of more than 1,000 customised systems.

A test centre for pharmaceuticals is available at Lödige’s facility in Paderborn, Germany, for process development and achieving a reliable scale-up of machines on a production scale.

The test centre is equipped with all necessary devices for mixing, wet granulation, sieving, drying and coating, and meets the requirements of GMP-compliant series of trials and small production batches.

Pharmaceutical products such as ordinary or effervescent tablets are manufactured from powdery raw materials.

With coaters from the LC and LC light series, Lödige Process Technology offers two different machine concepts for the film coating of tablets. Pharmaceutical companies have a choice when looking for the optimum task-specific solution. Systems can thus be realised that precisely meet the respective requirements.

Due to improved product attributes, the agglomeration of powdered or fine-grained substances is continuing to gain in importance. Although this classical process still places special demand on the machines used in particular for high-quality products.

In view of the many advantages, continuous processes are also becoming more and more popular in pharmaceutical production. For the production of solid dosage forms Lödige Process Technology offers the pharmaceutical industry machines and systems that combine the continuous process with the proven GMP standards.

Most medication is taken orally and pressed into tablet shape for ease of use. In order to ensure reliable production of pharmaceuticals with optimal and reproducible quality levels, the raw materials are processed into free-flowing granules. Granulation involves various essential process steps such as mixing, liquid addition, accretion of granules and drying. The single-pot method developed by Lödige allows all of these steps to be performed in a single system, saving space, time and money.

Optimum process control guarantees the best results during tablet coating.

Nutraceuticals like vitamin preparations, mineral nutrients or dairy products, mostly contain more than 50 different products.

Characterised by a standardised design, Lödige Process Technology has developed the LC light series.

Enhanced process and tablet film coating quality.

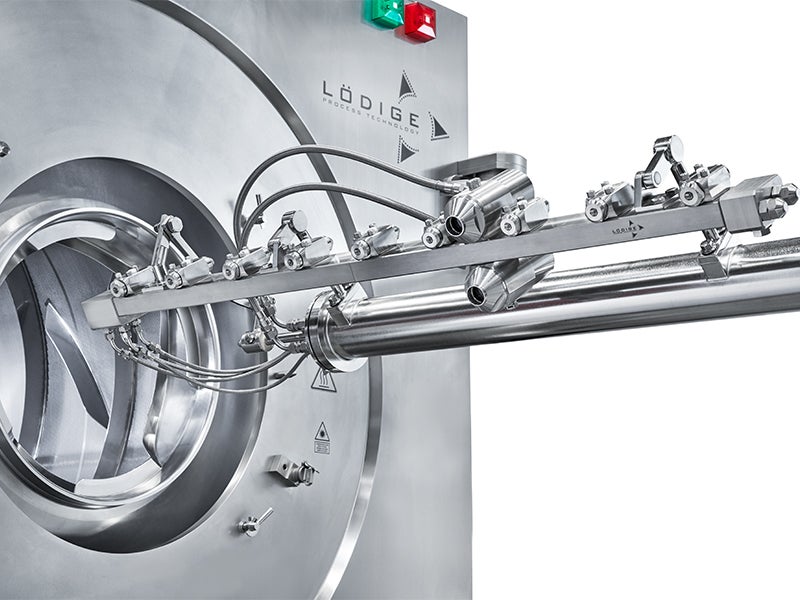

In addition to reliable process functionality, an efficient cleaning process of the horizontal mixing system like the Lödige Ploughshare® Mixer is becoming increasingly important.

To meet the highly specific requirements of the high-containment segment, Lödige Process Technology has developed the smallest machine in the entire history of the company.

Ploughshare® Mixers are proven systems that are used in the pharmaceutical industry. For many decades these machines have been successfully employed for mixing, granulating and drying high-quality pharmaceutical products.

Lödige shovel dryers are batch vacuum dryers whose mixing elements are frequency-controlled for ideal adaption to the process.

The Lödige fluid bed processor is designed for drying, instantizing, granulating and coating. The processor runs in batch operation.

During granulation, small particles are bonded to form larger clusters. The aim is to enhance the flow properties of the material for the downstream process stages.

Many products obtain their specific shape and property once they are covered or enveloped by particles, in a process known as coating.

The Lödige coating system, LC,ensures excellent tablet quality and optimal coating uniformity.