Sanitary Valves for Bulk Solids

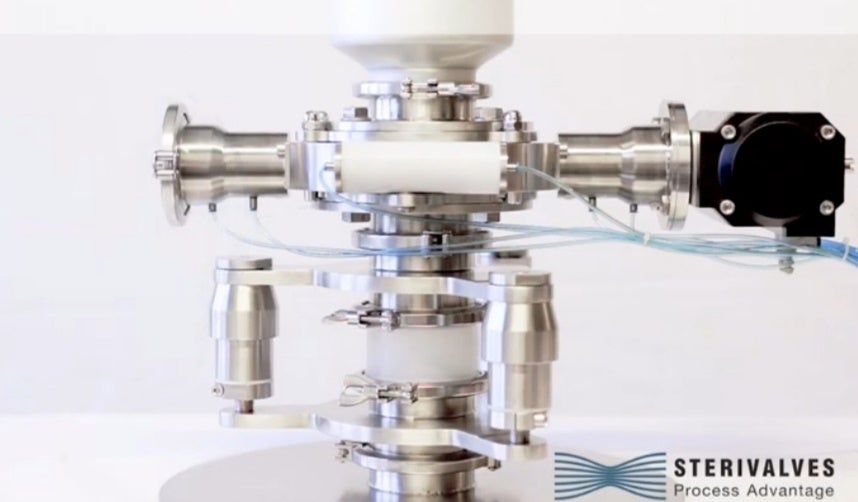

Sterivalve is part of the modular system (see modular system sheet). This valve is designed to interrupt bulk solid products (powders, granules, etc) flow.

SteriValves offers high-quality products and services to the pharmaceutical industry.

You have successfully submitted your enquiry. Someone from our company will respond ASAP

SteriValves offers high-quality products and services to the pharmaceutical industry.

We design and manufacture valves and accessories to adhere to the most applicable standards, with close cooperation of machine manufacturers and end-users.

Our core business is provided by interception butterfly valves and flow regulation rotary valves while remaining highly committed to developing innovative solutions and designing products such as SteriSplit, now at the point of reference for safe powder handling.

Containment is a critical issue throughout the pharmaceutical industry; it is crucial to preserve the safety of the operator, as well as the quality of the product. For this, Sterisplit is the solution.

Interception valves are butterfly valves comprising a vane that revolves around its axis to secure the free section down to close the passage, used when flow regulation is not essential.

The types of interception valve we provide include Sterivalve, Flexivalve and Pharmalite.

The flow regulation valve moving part is a rotor used to control the product flow rate through the cavity’s geometric capacity, as well as by the actuator speed.

Flow regulation valves we offer include Rotovalve Light, Rotovalve Plus and Rotosphere.

Fine dosing valves such as our Rotodoser are in place to ensure accurate product dosing. The valve has two moving parts, the main rotor to discharge the bulk of the product, as well as a small rotor to achieve precision.

Independent functioning of the two rotors allows fast and precise dosing, which is impossible with other valves.

Suitable for applications where the operator or product protection is pivotal to plant operation, high containment valves such as SteriSplit are composed of two half-valves, an active valve that carries the actuation, and a passive valve.

Once the two parts meet, the two half-vanes form a single interception device that allows product transfer. After discharge, the two half-valves limit environmental contamination.

Deviation valves for solid bulk products, such as our Diverter, comprise one inlet and two outlets. An interception device diverts product flow from one outlet to the other outlet alternatively.

A lump breaker, also known as a de-lumper, is a device used when powders form aggregates. These devices, such as our Rotocrusher, are used throughout the pharmaceutical sector in compliance with stringent safety and hygiene standards.

SteriValves works in accordance to the highest quality standards for manufacturing processes and the working environment. We work in compliance with quality criteria, both in processes and in working environment (ISO 9001:2015 and OHSAS 18001:2007).

We provide a wide range of accessories such as drums, part-turn actuators and motors, Silcap, Silend and vibrators.

Sterivalve is part of the modular system (see modular system sheet). This valve is designed to interrupt bulk solid products (powders, granules, etc) flow.

SteriValves was established in 1999 with the aim to supply high-quality products and services to the pharmaceutical, chemical, nuclear and food industries.

SteriValves will attend the upcoming Powtech in Nuremberg from 27 to 29 September 2022.

The case of an Italian company specialising in the production of APIs, pharmaceuticals and related packaging services.

From 3 to 6 May, SteriValves will exhibit at Pharmintech, the international event dedicated to the pharmaceutical, nutraceutical, cosmeceutical and biotechnology industries, which will be held at Fiera Milano Rho.

The pharmaceutical industry demands equipment that guarantees a safe and clean work environment.

The need for precision dosing of a product is one of the most frequent requests we receive from the pharmaceutical and food industries. It is sometimes necessary to divide a batch into smaller containers or packages; other times, it is essential to add an ingredient to a recipe with extreme precision and speed.

Vibrations are mechanical phenomenons whereby oscillations transpire around an equilibrium point, which can result in irritating sounds, as well as a waste of energy.

Those who work productively in ta pharmaceutical field understand the importance of maintaining a clean and hygienic process environment to guarantee product quality and purity.

Rotodoser is a solution developed for accurate dosing, comprising of two individually operated concentric rotors of varying volumes, which determine product flow and dosing.

Rotovalve Plus has been developed to assist with the feeding and volumetric dosing of bulk solid products.

Rotocrusher is a lump breaker with an output covering a flow rate from a 750 kg/h - 3 t/h.

Rotovalve Light is a rotary valve for use within the pharmaceutical field.

SteriSplit is a high-containment butterfly valve, which has been developed to safely transfer powders for sterile or potentially toxic products.

Rotovalve Light is a rotary valve for the pharmaceutical industry, designed to feed and continuously control the discharged flow, helping the product to be discharged homogeneously thanks to rotary alternating motion.

SteriValves' Rotometering Valve is a new advanced solution that guarantees increased dosing precision, speed and flexibility.