Gritgen Therapeutics has launched operations at its commercial GMP facility in Suzhou Industrial Park, China.

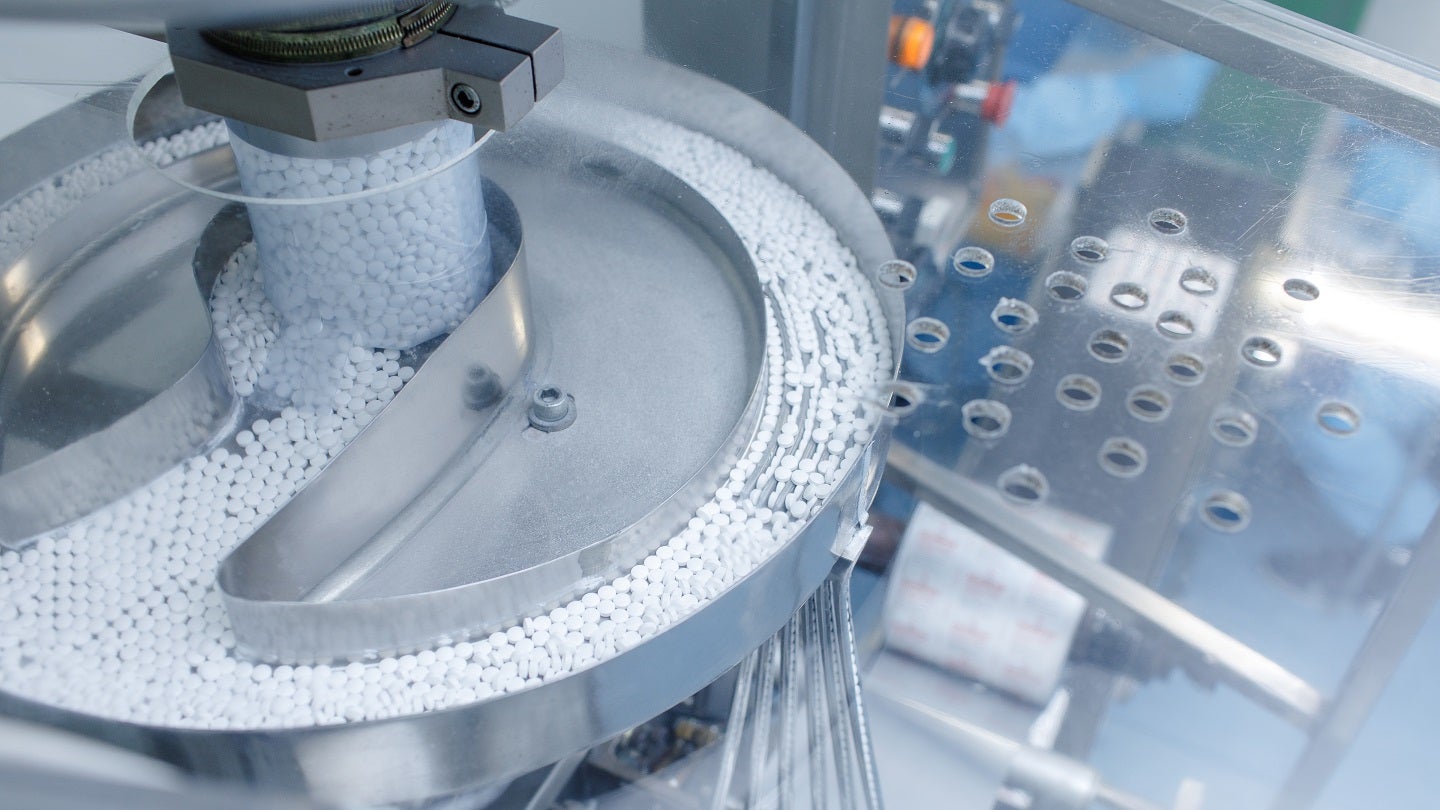

Gritgen will begin production of AAV [adeno-associated virus]-based products including its Phase III clinical and commercial product for haemophilia A.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

The 8,600m² facility covers plasmid production and AAV production lines.

The production lines are based on a downstream process with chromatography platform technology and an upstream process with mammalian cell suspension.

They are equipped with disposable bioreactors of varying scales, the largest with the highest capacity of 1,000 litres.

The facility also features pilot filling lines and commercial fill-finish lines to meet the needs of drug manufacturers.

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalDataA quality control laboratory covering physicochemical, biochemical, molecular biological and microbiological tests is also available.

Production lines in the facility are completely physically separated, controlling cross-contamination risk.

Gritgen Therapeutics co-founder and CEO Dr Wu Fenglan stated: “The validation and operational launch of our GMP facility represents a pivotal juncture for Gritgen, which provides an important vector foundation for the company to realise commercialisation.

“At present, a bottleneck of gene therapy is the manufacturing process, a challenge resonating globally.

“The production capacity of large-scale, high-quality, cost-controllable vectors is an important driving force for the development of the gene therapy industry.”

Cell & Gene Therapy coverage on Pharmaceutical Technology is supported by Cytiva.

Editorial content is independently produced and follows the highest standards of journalistic integrity. Topic sponsors are not involved in the creation of editorial content.