piFLOW®p SMART

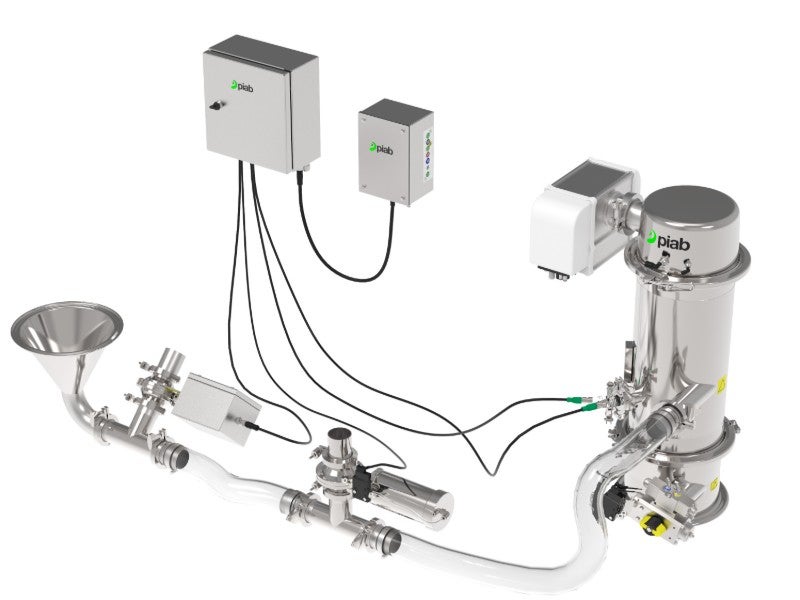

piFLOW®p SMART is based on the traditional piFLOW®p technology. piFLOW®p SMART is a stand-alone system with machine learning software and sophisticated algorithms that run the application to reach the maximum capacity for the conveyed material, basically, it is a self-optimising conveying system.

To reach the maximum material capacity an air carrying unit is integrated into the piFLOW®p SMART system. The carrying air ratio is automatically set and continuously adjusted during the entire cycle using algorithms. Eliminating the need for manual feed adapter tuning, this guarantees optimal transportation of materials and ensures applications run at premium capacity.

If there is a vertical lift higher than 8 meters in the conveying pipeline, Piab is offering a pipeline emptying unit to prevent blockage of the pipeline.

All the vacuum conveying functions are controlled by the electrical control unit ECU-15S and its software.

Integrated into the main body module are two sensors, that does not only prevent overfilling, risking damaging the filters, they are also used to optimise cycle time, by calculating expected emptying time, which increases productivity.

piFLOW®p SMART is a self-optimising vacuum conveyor targeting primarily at industries handling many different materials and/or those in which frequent changes need to be made and focusing on ease of use. This also means that even if there are not frequent material changes, but production capacity/stability is an issue, this system takes away the operator interference from the operator, adjusting traditional process parameters by operators are now fully automated. piFLOW®p SMART uses machine learning to automatically tune the process, resulting in a flawless flow of materials. Smart enough to configure itself and quickly adjust settings, considering environmental conditions such as temperature and humidity, it beats even the most experienced operator adjusting process parameters every time! Operated through a user-friendly touch screen, piFLOW®p SMART is easy to learn to use and operate. Installation is straightforward, and built-in features, such as the anti-blockage function and air-assisted sensor cleaning, resulting in a system that requires only a minimal amount of maintenance.

piFLOW®P smart is available in four different sizes, from five litres to 33 litres, covering most of the applications and throughput needs within the food industry.

Due to built-in intelligence, all manual settings are removed, and fully automated and as consequence, piFLOW®p SMART is only offered with vacuum generators based on coax technology.

Customer benefits:

- The level sensors guard against overfilling and monitor the emptying process.

- In each cycle, sensors are cleaned by a shock of air, ensuring long life and optimal function.

- The ability to store material settings to speed up the start process next time the material is conveyed.

- Easy to learn and use, thanks to the user-friendly touch screen and self-adjusting settings.

- Operator-skill independent, thanks to software, sensors and air carrying unit.

- Anti-blockage function ensures a safe and smooth conveying.

- Air-assisted sensor cleaning results in a system that requires only a minimal amount of maintenance.

This system is: “To automate and simplify the vacuum conveying process and make life easier for our customers by delivering a SMART solution- solving known customer pains.” In essence this main, you install the system- fill-in material- and push the start button- and conveying starts, and within two minutes is running at full production capacity, continuously adjusting the parameters for any changes.

piFLOW®p SMART can be operated fully automatic (recommended), semi-automatic, or in manual mode (conventional standard conveyor)

There are six types of different filter types available, all with a standardised interface, so different filter types can be used in the same conveyor, all depending what material that is conveyed at different times. The filters have different total filter area, and filters available from 0,5 µm to 5µ. There is always a filter suitable for different materials. (Everything from bridging, sticky and free-flowing materials).

Filters are automatically cleaned by at least one filter shock after each conveying cycle, and available with up to 5 shocks, depending on chosen setting through HMI. The system can be equipped with a vibrator, but our tests show that the optional fluidisation function works better for bridging / ratholing materials.

Naturally- all components that are in material contact have all the global certificates to fulfil the high demands within food processing needs, such as FDA, EN1935 / 2004 and EN 10 / 2011.

Significant for all conveyors is safe material transport compared to other ways of moving materials.

piFLOW®p SMART comes with an annual service package including software upgrades and system check-up.