Serologicals Corporation finished the construction of a new biotechnology production facility in Lawrence, Kansas, US, in April 2004. The new 45,000ft² facility was constructed to manufacture the company’s new serum-free cell culture supplement, EX-CYTE, for use in the preparation of media for biopharmaceutical production. The plant was constructed on a 12.5-acre site in the East Hills Business Park in the south eastern part of the city of Lawrence along the K-10 corridor. The project cost was reported as $28m.

The site was chosen from more than 30 other possible cities in the USA. The reasons for the choice were given as the proximity of the University of Kansas and its team of life science experts and the incentives offered by the City and the State in the form of tax credits and abatements, which were granted in January 2003 just before the ground breaking ceremony.

The University of Kansas has an unrivalled reputation for its expertise in biotechnology and the company has forged strong links with the university by locating to Lawrence and also by funding a student scholarship scheme.

The company could receive nearly $3m in tax credits from the State if it fulfils its wage and training requirements. The new plant will create 40 jobs, and the average wage per new employee is set to be $47,000 per year.

BIOTECH PRODUCTION PLANT CONTRACTOR AND CONSTRUCTION

The construction contract for the plant was awarded in December 2002 on a design/build basis. The designer was Clark-Richardson and Biskup (CRB) Consulting Engineers Inc., of St Louis. The construction contractor was Clark-Richardson and Biskup (CRB) Builders LLC of Kansas City. Construction started in the first quarter of 2003 and was scheduled to be complete within 15 to 18 months; it opened on 23 April 2004.

The plant was designed to manufacture 100,000l of EX-CYTE per year from two processing suites. Long-term plans were made for an expansion to four processing suites if the demand for the product increased. The Phase 2 expansion could be carried out at minimal cost since the first phase building allowed additional space.

The first phase building was constructed with four distinct areas: administrative, warehousing, processing/production and utility. The facility was designed to exceed all cGMP design requirements. The other design features of the building include a single central corridor for ease of communication and good process control.

The building also has security controlled inward and outgoing areas, classified production suites, pharmaceutical grade materials in the construction and supporting utilities including Clean in Place (CIP) systems, clean steam and high purity water (Water for Injection). Validation of the facility by regulatory bodies and customers started in April 2004 and was completed by September 2004.

EX-CYTE GROWTH ENHANCEMENT MEDIA SUPPLEMENT

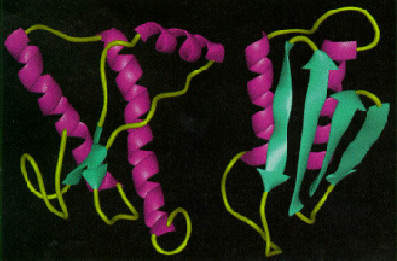

EX-CYTE is a growth enhancement media supplement manufactured from bovine serum. This processed serum is then marketed as a concentrated mixture of cholesterol, lipoproteins and fatty acids that can replace animal serum in cell culture when used in combination with other media components. However, it is mainly used for supplementing serum-free media to boost cell growth and productivity. The obvious advantages of using serum-free media is that there is no possibility of a biopharmaceutical batch being contaminated by microorganisms or prions, which could occur with animal-based serum media.

In the first quarter of 2004 Serologicals Corporation were awarded a patent on the purification process used in the manufacture of EX-CYTE that inactivates prions; the patent will run to 2021. EX-CYTE sales increased by 90% during the period 2002-03 and the product was evaluated by 100 companies in 150 different projects.

The product is certified using 9 CFR 113 to be free of bovine viruses and mycoplasma. It is also heat pasteurised and guaranteed to be free of organic solvents and detergents.

The bovine serum which forms EX-CYTE is purified by a combination of Serologicals prion removal technology, sterile filtration processes, charcoal stripping, ethanol precipitation/fractionation, dialysis and the use of specific binding columns for Immunoglobulins such as IgG.

PLANT CLOSED AND SEROLOGICALS BUYOUT

In January 2006 Serologicals announced plant consolidation across the company. This resulted in a decision being made to move all of the manufacture of cell culture products to the Kankakee, Illinois plant and to close the new Lawrence facility before it really got started in production. Consequently the Lawrence facility was written off against the fourth quarter of 2005 financial results and was put up for sale.

In July 2006 Millipore completed its acquisition of Serologicals Corporation for the sum of $1.4bn. Millipore gained R&D capacity and also a global sales team. In addition Millipore has gained access to the biological and bioprocessing market of Serologicals Corp. The Lawrence facility is still mothballed and its fate at the current time has not been decided.