When formulation scientists in the lab want to develop new drug products, they typically use small equipment to make tablets either by lack of powder available, cost of API or for ease of use.

What happens fairly often when a formulation is being transferred from lab onto production machinery, is that only at the scale-up stage tablet defects start to show. Those defects originate from the different size of the equipment as well as from the higher production speed at which those tablets are made.

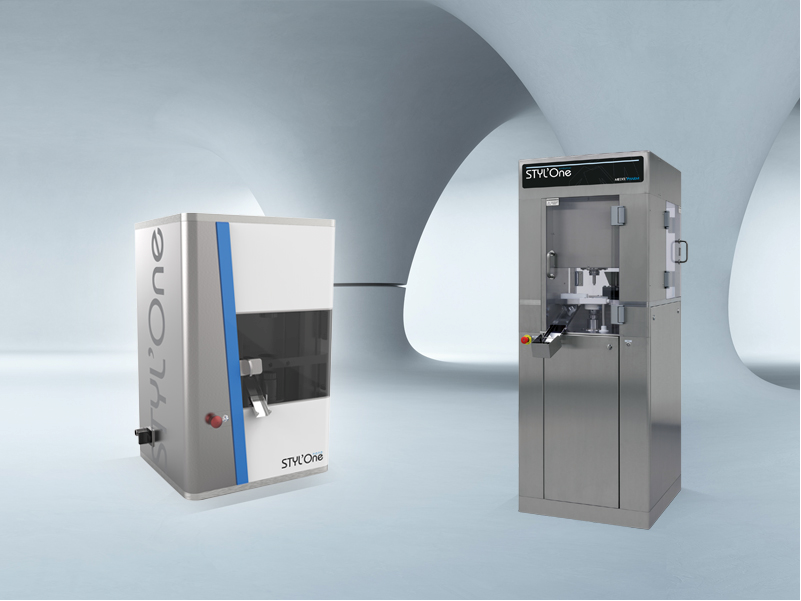

Compaction simulators

More than 30 years ago, people started to think of having systems in the lab that could replicate the dynamics or kinetics of the industrial-sized rotary tablet presses.

Those lab machines are called Compaction Simulators.

These R&D machines are built to mimic the kinetics of the punches and they can move those at the same speed as in production.

At Medelpharm, we have designed a new concept of compaction simulators, which has now become affordable for most scientists. The STYL’One boils down to one-third of the previous price with double the versatility.

We are using servo motors from the latest technology which deliver speeds which were reserved to servo-hydraulic actuators. Medelpharm was the first company to introduce a technology called ‘planetary roller screws’, allowing us to squeeze the size of the press, but still keeping performances similar to the hydraulic system.

This technology enables us to mimic the kinetics that is required to confirm that the formulation is scalable. On top of that, we are also capable of adding sensors on those instruments to gather more in-depth knowledge of the compaction itself.

All the above combined with in-house developed software, that offers the customer a perfect ease-of-use in performing complex functions, make our instruments unique on the market.

The result is a powerful R&D tabletting instrument with a user-friendly data acquisition.

Assessing feasibility of granulation

There are three ways to prepare your powder formula before compaction.

Either you are in a position to directly compact that powder with active ingredients. This is called direct compression.

Unfortunately, not all active ingredients are suitable for direct compression.

The second process is the wet granulation, where some liquid and binders are added onto the blend and are then dried to form granules. These granules flow very well and they allow you to transfer it into a tablet press, but the cost of such a process is high.

And the third type is called dry granulation. You need a separate piece of production equipment called roller compactor. Availability of this equipment, as well as the amount of API, needed to make this evaluation very costly in R&D.

With the help of a dedicated piece of software, Medelpharm has developed a solution where we can use our instruments to mimic that dry granulation process on our press.

The key point is that we are easily targeting different density using a small amount of material. It’s called a material sparing method, wherewith 20g of API, you’re able to assess if you would be able to use a dry granulation process.

Dry granulation is an inexpensive process compared to wet granulation, hence the interest.

It’s something fairly new on the market and technology now enables to assess easily this dry granulation with a very small amount of material.

Bruno Leclercq is the strategic marketing director at Medelpharm. Click here to find out more about the company’s technologies.